BIZTRACKS

Continuous Improvement Model for Reducing Salmonella in Poultry

Credit: Elanco

Since the U.S. Department of Agriculture (USDA) launched its initiative to reduce the number of Salmonella illnesses associated with poultry, there has been an increased focus on the importance of pre-harvest food safety solutions. Part of USDA’s initiative includes increased quantitative microbial monitoring of incoming flocks to processing plants, focusing on serotypes of concern.

Practical, data-driven approaches to measuring and improving Salmonella loads at pre-harvest exist, such as increasing flock monitoring for quantitative bacteria and the use of a pre-harvest food safety model based on continuous improvement (CI).

Pathogen reduction is most successful when various strategies are implemented at multiple points along the supply chain, from farm to processing plant. Improved technologies in Salmonella quantification and detection pre-harvest have made measuring the impact of pre-harvest interventions easier.

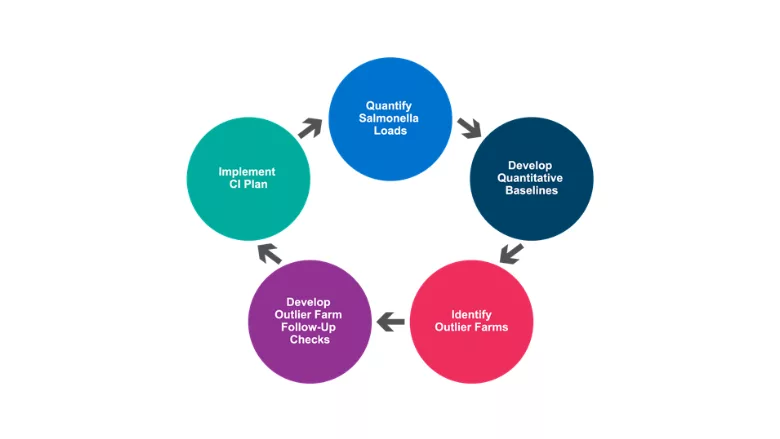

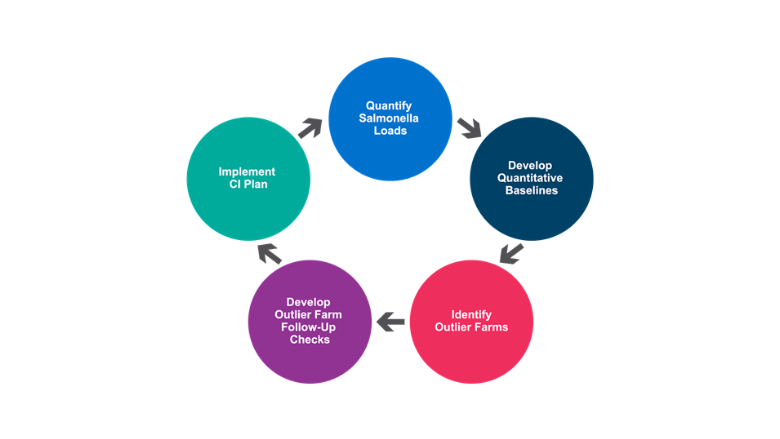

Data can be a powerful tool in driving decisions. Every CI process is based on data that is collected periodically or continually to describe and understand the process, and principles of the traditional “Plan, Do, Check, Act” cycle of CI can be applied to pre-harvest food safety. A practical approach to the cycle can be broken down into the following five steps, as depicted in Figure 1:

Step 1: Quantify Salmonella Loads

Quantitative measures for Salmonella can provide an accurate picture of incoming loads to plants, which, when converted to log counts for best interpretation, allow managers to not only confirm the presence of Salmonella but also understand the extent of the pathogen’s presence. Sample collection can be scheduled for random flocks or be ongoing.Lab technologies have improved significantly in recent years, making it easier to obtain quantitative measures of Salmonella. Some of these measurement techniques include quantitative polymerase chain reaction (PCR), most probable number (MPN) methods, and automated mini-MPN methods.

It is also essential to determine which pre-harvest measurement is most relevant to each complex. For example, measurements can be taken at the farm (i.e., boot covers, environmental swabs, cloaca swabs, etc.) or at the plant (i.e., pre-scald rinses, hot rehang, or ceca sampling). It is important to focus on a limited number of measurements to start; fine-tuning the data collection process can happen over time.

Step 2: Develop Quantitative Baselines

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Mangers have multiple options when designating baselines for each plant or complex. Using principles of statistical process control (SPC), baselines may be developed by taking a specified number of samples per farm, and determining the complex mean and standard deviation.

The management team can then determine an acceptable baseline standard for the complex to identify outliers. For example, a baseline standard may be developed according to the upper 80th or 95th percentile, or by setting upper limits based on SPC principles using standard deviations. Statisticians or SPC experts can help develop practical baseline standards.

Step 3: Identify Outlier Farms

Once the quantitative baselines are determined, ongoing monitoring consists of taking a set number of samples per farm or per week. Complexes may choose to sample all farms or a percentage of farms based on lab capabilities. If not tested weekly, flocks should be tracked to ensure that they are all sampled periodically throughout the year.

To best understand flock quantitative loads, it is optimal to take multiple samples in a flock and then average the results for that flock. If a flock is historically high in Salmonella loads, management may choose to take additional samples for those flocks.

Outlier farms would be identified as farms with quantitative results higher than the designated baseline standard for that complex.

Step 4: Develop Outlier Farm Follow-Up Checks

Once outlier farms are identified, company field service supervisors, managers, veterinarians, or designees can conduct follow-up farm audits. An audit checklist can be designed based on best management practices to prevent or reduce Salmonella on the farm.

The checklist should include all factors on the farm that could contribute to pathogen loads: biosecurity practices, integrated pest management, litter and water management, bird health, and other components.

Step 5: Implement CI Plan

After a thorough audit of outlier farms, a formal CI plan can be created to help reduce Salmonella loads. The plan may include a combination of actions recommended by technical experts inside the company or based on external vendor resources.

Common initial CI steps may include:

- Reducing litter moisture

- Increasing pest elimination

- Modifying house cleanout

- Implementing Salmonella vaccines

- Using probiotics or other supplements

- Implementing litter amendments

- Improving water treatment.

A CI plan can be customized to each farm or all outlier farms. Rather than being a fail-pass approach, this process focuses on CI over time.

Vendor Partnership in the CI Process

As part of the food safety CI process, poultry companies can leverage vendor partners to help develop new strategies, technologies, and ideas to address pathogen concerns. Vendors can offer services such as serotype lab analysis to verify vaccine effectiveness, field evaluations to understand the impacts of feed additives, and vector analysis to measure the effectiveness of insecticide rotations in reducing farm pests.

Elanco’s food safety advisors, veterinarians, nutritionists, and technical consultants can help drive CI in pre-harvest pathogen reduction.

Elanco: www.salmonella360.us