How Proactive Listeria Testing Helps Prevent Six- and Seven-Figure Recalls

Recent multistate recalls prove that one missed Listeria cell can shut down production and erode consumer trust. Learn how proactive PCR-based testing and data-driven monitoring protect food brands.

A Costly Wake-Up Call

In 2025, there have been five to ten recalls linked to Listeria contamination. According to the U.S. Food and Drug Administration (FDA),1 when a food product poses a reasonable probability of causing serious illness or death, a company may be asked or required to initiate a recall. In outbreaks involving Listeria monocytogenes, the risk is particularly high, as symptoms can be mild yet lead to severe and sometimes life-threatening complications in vulnerable groups.

The average cost of a Class I recall in the U.S. now exceeds $10 million2 in direct expenses, not counting litigation, retailer penalties, and long-term brand damage. For small and midsize processors, one contamination event can threaten viability altogether. To avoid those losses, food manufacturers are adopting validated molecular testing solutions3 that deliver rapid, accurate results and support audit-ready compliance.

Why Listeria Remains a Persistent Threat

Unlike many pathogens, Listeria monocytogenes4 thrives where most bacteria perish. It can survive in cold, damp environments, where biofilms and residual moisture protect it from routine cleaning. It can survive refrigeration, freeze–thaw cycles, and standard cleaning, if sanitation gaps persist.

Since ready-to-eat (RTE) products often lack a final kill step, microscopic cross-contamination with raw materials or environmental exposure can make its way into finished goods. In 2025 alone, FDA and the U.S. Department of Agriculture's Food Safety and Inspection Service (USDA-FSIS) issued over 50 Listeria-related recall notices, spanning frozen entrées, deli meats, dairy, and fresh-cut produce.

Beginning in January 2025, USDA-FSIS expanded its testing to detect all Listeria species5 on food contact surfaces, a move signaling that regulators expect processors to move from reactive to proactive monitoring.

The Hidden Costs of Waiting for the Lab

End-product testing at batch release is too little, too late. By the time contamination is detected in finished goods, the product is already packaged, shipped, and potentially consumed.

Every testing delay adds risk and cost. What looks like a short wait in the lab can quickly cascade into operational losses:

- Storage and hold costs: Chilled warehouses fill while results are pending.

- Rework and disposal: Destroyed product adds material waste.

- Audit pressure: Unvalidated methods can fail under regulatory review.

- Consumer trust: One social media photo of a recall notice travels faster than any press release.

In today's 24-hour news cycle, prevention is not just about compliance; it is about survival.

When Testing Happens Outside Your Walls

For many food processors, third-party laboratories are essential partners in ensuring objective, defensible results, especially for environmental monitoring and regulatory verification. However, outsourcing can introduce unavoidable time gaps: every shipment of samples must be logged, transported, queued, and processed before results return. Those added hours or even days can delay product release and create scheduling pressure across the production line.

The most effective programs strike a balance between external verification and internal visibility. Many brands now pair contract lab testing for confirmation with rapid in-house screening tools, allowing facilities to identify potential issues early while still relying on accredited labs for official confirmation. Hygiena® supports both approaches, offering validated PCR assays like the BAX® System Q76 or foodproof® assays3 and easy-to-use environmental monitoring tools that integrate seamlessly with external laboratory workflows.

Building a Proactive Monitoring Program

Effective environmental monitoring is built on four pillars:

- Frequent, zone-based sampling: High-risk areas (e.g., drains, joints, conveyor undersides) should be tested pre- and post-operation.

- Rapid screening tools: ATP tests verify cleaning efficacy in minutes; presumptive Listeria genus screens flag contamination within 24–48 hours.

- Molecular confirmation: PCR assays validate presumptive positives with definitive results.

- Digital recordkeeping: Trending data pinpoints recurring trouble spots before they escalate.

When these steps are integrated, detection shifts from post-event confirmation to real-time prevention.

Case in Point: West Liberty Foods

When West Liberty Foods,7 an award-winning U.S. co-packer of sliced meat and cheese, faced unreliable results from its previous PCR platform, the company halted testing entirely until a better option emerged. After adopting the BAX® System, its corporate lab regained confidence in DNA-based detection.

"With just 24 hours of incubation, we save an entire day compared to our previous method," notes the laboratory manager. "The BAX® System's [lyophilized] reagents reduce setup time and eliminate mixing errors."

The switch also freed bench space and cut consumable costs by removing redundant control runs. Most importantly, consistent results meant fewer product holds and stronger audit performance, proof that validation and efficiency can coexist.

Why Validated PCR Matters

Regulators and auditors alike now expect laboratories to employ globally recognized validations (e.g., AOAC, ISO, Health Canada, AFNOR, NordVal). Validated methods ensure reproducibility across matrices and labs, giving processors confidence in the data, when inspected.

Hygiena's molecular portfolio, anchored by the BAX® System Q7 and foodproof® assays, delivers detection for Listeria, Salmonella, E. coli O157:H7, Cronobacter, spoilage organisms, and many other microorganisms of public health concern. Internal controls and multiplex PCR designs minimize retests and false negatives, enabling faster release decisions that directly reduce inventory costs.

Four Tips for Smarter Listeria Testing

- Choose sampling tools that technicians will actually use: Hard-to-reach drains and seams require ergonomic devices. All-in-one tools such as InSite® Listeria simplify collection and testing and boost compliance.

- Screen broadly, confirm precisely: Use genus-level PCR screens to broadly detect potential contamination, then confirm and, where applicable, quantify results for greater precision.

- Tailor enrichment protocols: Different surfaces and swab materials influence recovery. Hygiena's applications team tested 13 enrichment conditions for environmental sponges to confirm that BAX® System Listeria assays deliver accurate results with any sample or method. Results from InSite® Listeria screens can also be confirmed using the BAX® System for definitive identification, providing a clear, streamlined path from presumptive detection to validated confirmation.

- Invest in people and training: Even the best technology depends on skilled technicians who know how to interpret and act on results. A strong food safety culture is not about avoiding positives—it is about responding quickly, tracing the source, and preventing issues before they escalate into recalls.

Turning Data into Decisions

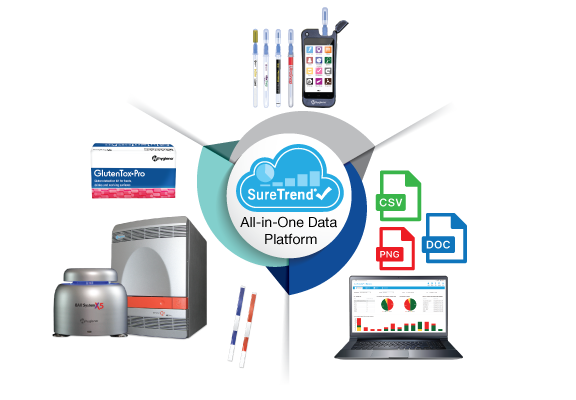

Modern facilities generate thousands of data points weekly, from ATP results to PCR cycles. Centralizing those insights turns reactivity into prediction.

Platforms like SureTrend® software, integrated with the EnSURE® Touch luminometer8 and the BAX® System, visualize contamination patterns across rooms, shifts, and sites. Managers can compare facility performance, set alerts, and demonstrate continuous improvement during audits. The result: fewer surprises, faster corrective actions, and measurable ROI through reduced downtime and waste.

Beyond Listeria: A Comprehensive Approach

While Listeria dominates headlines, most recalls involve multiple pathogens or spoilage organisms. Hygiena's integrated solutions cover:

- Pathogens: Listeria, Salmonella, E. coli, Cronobacter, and others.

- Spoilage organisms and yeast/mold: Aspergillus, Alicyclobacillus.

- Allergens and GMO verification using foodproof® PCR.

- Environmental water testing via microproof® assays.

Consolidating these solutions under one data platform simplifies training, validation management, and reporting, reducing the total cost of ownership across quality assurance programs.

The Bottom Line

Every recall tells the same story: a missed hotspot, a delayed result, and a brand left to rebuild. With proactive testing and validated molecular tools, those outcomes are avoidable.

Preventive testing is not just compliance; it is an investment in uptime, brand equity, and consumer trust. Before the next recall makes headlines, evaluate whether your monitoring program could catch contamination today—not after tomorrow's audit.

Call to Action/Contact

Don't wait for a recall to review your food safety protocols. Explore Hygiena's suite of environmental monitoring and molecular diagnostics solutions to safeguard your operations from costly disruptions.

https://www.hygiena.com/pathogen-and-spoilage-organism-detection

References

- U.S. Food and Drug Administration (FDA). "Investigations of Foodborne Illness Outbreaks." Current as of October 22, 2025. https://www.fda.gov/food/outbreaks-foodborne-illness/investigations-foodborne-illness-outbreaks.

- Food Safety Magazine Editorial Team. "Recall: The Food Industry's Biggest Threat to Profitability." Food Safety Magazine. October 11, 2012. https://www.food-safety.com/articles/2542-recall-the-food-industrys-biggest-threat-to-profitability.

- Hygiena. "Real-Time PCR Pathogen Detection for Food Safety Testing." https://www.hygiena.com/food-safety/pathogen-detection.

- U.S. Centers for Disease Control and Prevention (CDC). "Listeria Outbreaks." March 17, 2025. https://www.cdc.gov/listeria/outbreaks/index.html.

- U.S. Department of Agriculture (USDA). "Constituent Update—July 11, 2025: FSIS Publishes Article on Modernizing Campylobacter Screening Process." July 11, 2025. https://www.fsis.usda.gov/news-events/news-press-releases/constituent-update-july-11-2025.

- Hygiena. "BAX® System Q7." https://www.hygiena.com/instruments-and-automation/real-time-pcr-instruments/bax-system-q7.

- Hygiena. "BAX® System Helps West Liberty Foods Save Time and Money." https://www.hygiena.com/news/bax-system-helps-west-liberty-foods-save-time-and-money.

- Hygiena. "Food Safety Data Management: SureTrend®." https://www.hygiena.com/analytics/suretrend-analytics.

By Hygiena