Building a Culture of Hygiene in the Food Processing Plant

One of the crucial building blocks for a successful food safety or quality culture is basic food hygiene

It seems that today's world is becoming one of different cultures in all walks of life and business. In the food processing and handling industry, "food safety culture" is a growing and evolving concept. Food quality cultures have been established in the past, but the fact remains that one of the crucial building blocks for a successful food safety or quality culture is basic food hygiene. It is a logical progression that the industry must make a commitment to creating a hygiene culture. Far too many problems can be traced back to failures in basic hygiene such as poor cleaning, insufficient pest management, inadequate personal hygiene, improper clothing, or a failure to follow basic procedures.

In 1778, Reverend John Wesley used the phrase, "Cleanliness is next to Godliness" in a sermon. He was urging his parishioners to live a clean life with God and humankind. The author mentions this because of the importance of cleanliness in the world of food and how the commitment to what seems so simple can minimize a myriad of problems in a society that seems to become more litigious by the day. It is imperative that processors try to do all that can be done to protect their business.

So, where does hygiene start in a food processing facility? How about the entrance(s) to the facility? This means the front door where visitors and office staff enter, the access point(s) for plant workers, and the entryway that more and more facilities have established—the trucker's entrance. Depending upon the operation, there may be another one or two entrance points.

Building Access

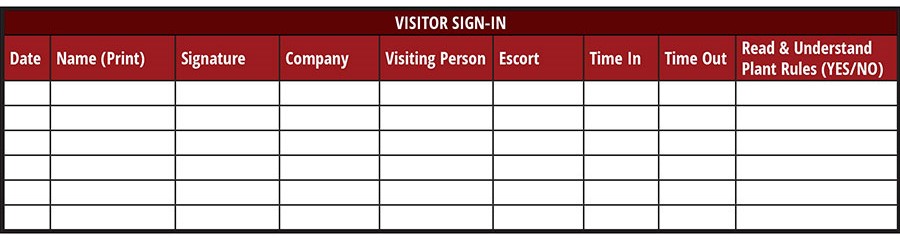

Everyone entering a food processing facility needs to know and adhere to a set of rules that address food safety, basic sanitation, proper hygiene, and safety. This includes visitors of all kinds—customers, regulators, auditors, salespeople, and any other visitors. This is something that an auditor will expect to see, and it will be included in the auditing process. The expectation today is that anyone entering the facility will be presented with a list of plant rules that they must read, as well as a form they must sign acknowledging that they have read and understand the rules. The sign-in form may look something like that shown in Figure 1.

The rules vary between plants, but they will usually include requirements regarding the following:

- Handwashing

- Clothing

- Hair and facial hair covers

- Jewelry

- Makeup and perfume

- Illness/injury

- Cellphones

- Photography

- Escorts.

Details as to what each of these points require in terms of hygiene will be addressed later in this article.

Some operations have set up small projection rooms near access points. Visitors of all persuasions will be asked to watch a short video that addresses plant rules; a picture is worth a thousand words. The visitors are then asked if they understand the rules and to sign a form that they watched the video and understood the contents. The author has also visited facilities over the past few years that have a second set of rules addressing COVID-19 protocols.

What is Expected from Visitors and Staff

Visitors to a facility only need to read and understand the rules and follow them. They will also be escorted whenever they are in the production area or warehouse, so there will be a member of the team supervising their conduct within the facility. The supervising staff will be expected to remind or reprimand a visitor if an incident occurs that is against the rules.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

The author witnessed such an incident during his work in industry. A corporate staff member from the main office visited the plant and wanted to tour the production floor. A junior member of the quality group refused to let him onto the floor until he was properly kitted up—meaning a hair net, work coat, proper shoes, etc. The corporate guy ranted and raved in response to the request, and then stormed upstairs to the main office with the quality person trailing behind. He burst into the plant manager's office and demanded that the junior quality worker be fired. After getting to the bottom of what had happened, the plant manager brought the quality worker into his office, commended him in front of the corporate guy, and asked that the man apologize because the quality worker had done his job.

The procedures and restrictions making up the plant rules are all elements of a good hygiene culture and are there to minimize the potential for cross-contamination of foods, equipment, utensils, other people, and ultimately your customers. Some of these rules have other roles, such as personal safety.

Handwashing

Handwashing is perhaps number one on the list of good hygienic practices that protect products and people. Every year, numerous outbreaks are caused by fecal-to-oral transmission of pathogens. Processors must mandate and indoctrinate their employees on the importance of good handwashing practices. They must ensure that the facility is equipped with enough hands-free handwashing stations, and that these stations are properly supplied at all times. Instilling handwashing discipline starts with the orientation of new employees, continues with yearly (or more frequent) refreshers, and perhaps includes surprise hand swabbing.

Two excellent programs can be used to help demonstrate the importance of handwashing. One is to bring your team together and have several individuals place their unwashed fingertips on petri dishes with plate count agar. Have them wash and dry or wash, dry, and sanitize their hands, and then repeat the exercise. It is a graphic demonstration of the efficacy of handwashing. Another program entails the use of a proprietary hand oil, followed by handwashing and examination of the hands under ultraviolet (UV) light to expose how well the person has washed their hands.

Clothing

Clothing should be designed to be comfortable, yet pose no potential risks for product contamination. Buttons and chest or shoulder pockets should never be part of the uniform or clothing provided to plant workers. Buttons can pop off and end up in product, so snaps or Velcro are recommended. If the garb has pockets above the waist, one tempts fate. Someone will put something in the pocket that can fall out into product on the processing line. Many operations mandate that the shirts, lab coats, or smocks they provide have long sleeves with elastic wrist bands at the end to further protect product from sweat or hair shedding. Uniforms should be tight-fitting and made of materials that do not easily tear or shred and are easily cleanable. This for both comfort and safety. Loose-fitting clothing can get caught in belts or moving parts and result in injury to the worker. The clothing must also be appropriate for the operation. People working in meat processing operations (which generally are held at 50 °F/10 °C or below) must be provided with warm clothes befitting the environment.

Most companies provide their plant or warehouse workers with some kind of uniform. What kind depends upon the type of operation. A processor whose operation consists of a "kill step" of some kind will clothe the workers on the "raw/uncooked" side of the plant with a uniform or hat of one color, whereas those working on the cooked side, after the kill step is implemented, will be outfitted with different colors. If one wishes to move between the two sides of such an operation, they must pass through a changing room, where they will wash hands and change uniforms and boots or shoes, to avoid cross-contamination from raw to cooked product. Some processors do allow their teams to work in street clothes, but these are typically low-risk products such as soft drinks. In these operations, the processing system is closed and the lines are high-speed, so the chances of product contamination are low.

Finally, let us touch on uniform cleaning. More and more companies have moved to a service that provides uniforms, repairs them, and picks up the clothing for cleaning. This can also be done in-house. The bottom line is, if a company does elect to use a uniform service provider, it is important to treat the candidates as one would any supplier—e.g., subject them to the vendor approval process, which includes conducting an audit of their facilities. It is important to ensure that the uniforms are not only being properly cleaned but that they are also being cleaned and handled under conditions that will ensure product safety and minimize the potential for contamination. Lastly, do not rely on your workforce to bring work clothing home and launder it themselves. I have seen companies who have established this as a policy and had it backfire on them.

Additionally, many companies will fund the purchase of a specific kind of work shoe that can only be worn in the plant. These are often non-slip and have steel toes or shanks for safety, and are cleanable.

Hair and Facial Hair Covers

Hair restraints are essential for all employees and must be worn so that all hair is covered and held within the restraints. Many companies mandate that hair restraints cover both the hair and ears to ensure that a worker's hair is fully contained. If a man is wearing a moustache and/or beard, then it must be covered with a snood (beard cover). Companies should not try to regulate how much facial hair a man can have before it must be covered; both pencil-thin and bushy moustaches need to be covered. Some plants have strict rules against facial hair, negating the need for snoods.

Hair restraints also have another benefit—worker safety. Many years ago, the author was asked to be an expert witness in a case in which a woman with long hair was killed because her hair became caught in the moving parts of a piece of equipment. It turned out that she had lobbied her boss to waive the hair restraint requirement because she did not want her hair to become messy.

Hats may also be worn, and the industry is moving toward mandating hats that can be easily washed and sanitized. This means that baseball caps are now forbidden in many plants. Why? Baseball caps go everywhere—fishing trips, softball games, gardening rounds. They cannot be cleaned well, and they are often downright filthy.

Jewelry

Jewelry is also not allowed in food processing facilities. Why? It poses a potential risk of product contamination. This includes visible piercings—even oral jewelry, such as a tongue piercing. The only pieces of jewelry that are allowed in some plants are plain wedding bands and medical alert bracelets or necklaces. The latter must be completely covered by a long-sleeved garment with elastic wrist bands. Medical alert necklaces must be worn underneath the shirt. Many operations mandate that any person wearing a plain wedding band must wear a glove over the hand with the band.

Let us not forget gloves. Most food processors mandate that any worker handling food must wear gloves of some sort, depending on the operation. The food industry has evolved in this area. Industries using disposable gloves now use gloves made of nitrile, as latex gloves are associated with severe allergies in some people. Many operations use gloves that can be worn repeatedly. If this is the case, then the workers and management need to monitor the gloves for wear and tear and replace damaged gloves. It is important to remember that just because one is wearing gloves does not mean that they cannot contaminate product. Gloves must be cleaned and sanitized or replaced if they get dirty or if someone does work away from the line, such as dumping a trash barrel.

The author has visited food processing facilities that post photographs of exactly how a worker or a visitor should dress, including a step-by-step progression of how each item—from smock to boots to hair nets—should be worn. This provides visitors with an excellent road map on how to dress, and a constant reminder to the workforce of what is expected of them.

Makeup and Perfume

Processors also need to establish policies regarding makeup, scents, and accoutrements like false eyelashes, nail polish, and false nails. These items are simply not allowed in food plants. Nails and eyelashes can fall into product; nail polish can chip, and makeup can flake off. Perfumes, aftershave lotions, and other scents may be absorbed by foods, especially foods that contain fats. These policies may seem discriminatory, but the bottom line is product and consumer protection.

Illness/Injury

The COVID-19 pandemic raised awareness around the world regarding contagion and the spreading of disease. This was an event in which the food processing industry was ahead of the curve. Most food processors had established policies regarding sick or injured workers and their participation in process operations. Some companies already mandated masks for workers in the pre-COVID-19 days.

The illness rule for food plant workers is very simple: if you are sick, then you do not work. This basic rule is addressed during orientations for new employees and during refresher sessions. Workers who have infections or open wounds either do not work (depending upon the severity of the wound or infection), or must keep the injury completely covered. The industry has evolved in the area of bandages. Today, processors usually maintain a stock of brightly colored (blue or green) metal-detectable bandages. The bright colors make them visible if they fall off, and the metal component allows them to be detected by a metal detector if they happen to end up in a food product. Of course, each delivery of metal-detectable bandages must be checked to verify that they are metal-detectable when they are delivered. A sub-sample from each lot will need to be tested.

Challenges with employee health are a continuing issue. It is up to workers to indicate to management that they are ill, and it is up to management to monitor workers to ensure that someone who is ill is taken off the line. Workers may not want to report a problem because they "need the hours," so what should a processor do? Hopefully, the company has a fair sick leave policy in place that allows people to miss a few days due to illness. Some companies deal with a sick employee by giving them a task where they are not exposed to products on the line or to other people.

If one has had a chance to travel in other countries, one may have observed much more stringent policies regarding worker health than those established in the U.S. Some countries subject potential food plant employees to a battery of tests including tuberculosis, blood tests, stool samples, urine samples, and a complete physical exam. Both new and existing employes can be subjected to this kind of screening. If they fail, then they are not allowed back to work until they test negative. This practice would be deemed "discriminatory" in the U.S.

Cellphones

Let us touch on another point: cellphones. Processors should mandate that personal cellphones be kept in the employee's car or locker. Cellphones pose a risk because they cannot be sanitized and they have a camera, which are not allowed in most plants and which are both a potential distraction and safety risk. Keep cellphones out of the plant and warehouse.

Photography

It is up to each and every food processor, handler, and warehouser to develop, document, and implement a policy regarding photography of their operations. This is a much greater challenge today compared to 20 years ago because nearly every cellphone has a high-quality camera with the ability to capture both pictures and video. Additionally, most people tend to carry their cellphones on their person at all times, which means they are always in possession of a portable camera/video recorder. With this in mind, every thorough photography policy must include a ban on cellphones within the plant, as explained above. This should be described in a separate policy that specifically addresses cellphones.

Food processing operations that are regulated by the U.S. Food and Drug Administration (FDA) must also factor the agency into their camera policy. Ideally, every processor or handler should have established, documented procedures on how to address a regulatory inspection—a procedure that should start with the receptionist or whomever is responsible for meeting visitors to the facility. The Investigations Operations Manual (IOM) emphasizes that FDA investigators have the right to take photographs:1

Since photographs are one of the most effective and useful forms of evidence, every photo should be taken with a purpose. Photographs should only be taken for evidentiary purpose, e.g., to document violations and environmental surface subsample sites. Photographs should be related to insanitary conditions contributing or likely to contribute filth to finished product, or to practices likely to render it injurious or otherwise violative.1

The IOM lists seven specific conditions or examples of insanitary practices that could be photographed:

- Evidence of rodents or insect infestation and faulty construction or maintenance, which contributes to these conditions

- Routes of, as well as, actual contamination of raw materials or finished products

- Condition of raw materials or finished products

- Employee practices contributing to contamination or to violative conditions

- Manufacturing processes

- Manufacturing and various control records showing errors, substitutions, penciled changes in procedure, faulty practices, deviations from GMPs, NDAs, or other protocols, altered or inadequate assays or other control procedures, and any variation from stated procedure

- Effluent contamination of water systems.1

The IOM also describes two court cases that support FDA's position on its legal right to take photographs. The food industry may not agree with FDA's policy, but industry must abide by it. One point that should be mentioned is that the photography policy may vary between investigators and districts. This situation has created some tension between the industry and FDA.

Now, this is not to say that pictures should never be taken in a warehouse or plant. There are many conditions that might demand a photograph or two. Examples would be the delivery of a damaged or contaminated load, or a photograph of a rail car or truck to verify that it was properly loaded and that dunnage is properly located. With these kind of situations, it is the responsibility of management to give a one-time approval to document the situation. An example of how a photography policy for a food processing facility might read is described in this article.2

Escorts

As previously explained, all visitors to a facility will be escorted whenever they are in the production area or warehouse. This means that a plant staff member will supervise their conduct within the facility at all times, and the supervising staff will be expected to remind or reprimand a visitor if an incident occurs that is against the rules. Neither visitors nor staff may bring unexpected visitors into the plant without approval from the appropriate person in charge. Also, it is recommended to record which staff member(s) served as the visitor escort(s) on the visitor sign-in sheet at the time of reception, in case any questions arise later pertaining to the visit.

Keeping the Plant Clean

An integral element of hygiene culture is making sure that the plant and grounds are kept clean. Most food processors have a dedicated sanitation crew that cleans up at the end of the day, usually on a cleanup shift. Cleanup crews have evolved over the years from what some might have considered the "dregs" of the workforce to a well-trained, well-paid group who take great pride in their work. Some operations reward cleaning excellence for different departments by pitting each operating group against one another for overall cleanliness. The group that performs the best for the week, month, or quarter are acknowledged among the entire workforce and given small bonuses, like grocery coupons, to reward excellence.

Most processors include pre-operational inspections of the processing lines, so the cleanup crews are evaluated not only by management, but also by the production staff prior to startup. If the lines were not cleaned properly, then production will flag the area that failed and hold up production until the area is cleaned and approved by the quality group. This wastes time and money, so the mantra for the cleanup crew is "Do it right the first time."

Educating the Workforce

Creating a culture of hygiene among plant workers starts with proper education. An integral component of education is not only teaching someone how to do something, but also successfully conveying why the work is important and how to do it the right way. In a food safety culture, quality culture, or hygiene culture, the ultimate goal is to ensure that the workforce understands why their tasks are important, their role in the program, and the consequences of failure to do the work as expected.

The educational programs should include orientations for new employees on food safety, quality, sanitation, and basic hygiene, as well as specific programs on how to do their assigned tasks, along with regular refreshers to review new or old issues. Hopefully, these programs will instill in workers a sense of pride in the processing facility, its products, and the company, so that they will feel their roles are necessary and important.

Management's Role

Of course, none of this is possible without a firm commitment from management. It is up to management to develop the policies and provide the financial and top-down support for the programs. One of the great strengths of the ISO 22000 food safety standard, "ISO 22000: Food Safety Management Systems—Requirements for Any Organization in the Food Chain,"3 is the emphasis on management commitment and its role in building and maintaining a food safety management system, in which good hygiene is part of the foundation. This element of ISO 22000 is now an essential element in the Global Food Safety Initiative (GFSI) and, therefore, part of most third-party audits.

Years ago, the author worked with a company that printed its quality and safety mission statement on its business cards. Understanding and working hard to meet this goal was ingrained in the management team, and they worked hard to instill the same spirit throughout the organization. The CEO would visit his plants regularly and would talk to staff at all levels. He would occasionally ask the person with whom he was talking if they knew the mission statement. Workers who did, and who repeated it to him, were instantly rewarded with a $20 bill. That information got around quickly, so people figured, "I think they mean it." And they did.

So, is cleanliness next to Godliness? It is, if one makes the commitment through management, education, and execution. Without commitment, cleanliness would be next to impossible.

References

- U.S. Food and Drug Administration. Investigations Operations Manual 2023. "Chapter 5: Establishment Inspections." https://www.fda.gov/media/166533/download?attachment.

- Stier, Richard. "Establishing and Implementing a Facility Photography Policy." Food Safety Magazine. October 3, 2023. https://www.food-safety.com/articles/8916-establishing-and-implementing-a-facility-photography-policy.

- International Standards Organization (ISO). "ISO 2200:2018: Food Safety Management Systems—Requirements for Any Organization in the Food Chain." November 2018. https://www.iso.org/standard/65464.html.

Richard F. Stier, M.S., is a consulting food scientist who has helped food processors develop safety, quality and sanitation programs. He believes in emphasizing the importance of how these programs can help companies increase profits. Stier holds degrees in food science from Rutgers University and the University of California at Davis. He is also a member of the Editorial Advisory Board of Food Safety Magazine.