The food-buying habits of American consumers are driven largely by perceptions of safety, according to a recent national survey commissioned by the United Egg Producers (UEP), the national trade association for egg farmers. Safety was ranked the most important variable when consumers shop for food, followed closely by price and whether the products are sourced locally—a new variable identified in our research. The research additionally found that consumers equate animal welfare with food safety: Good animal welfare is perceived to improve food safety; poor animal welfare is perceived to degrade food safety.

Consumers also consider themselves more informed about food safety and animal welfare issues than they did 10 years ago. These findings reinforce the importance of current developments in food safety taking place through government regulations and industry practices. The following article provides a historical overview of egg food safety guidelines, details recent developments and outlines what UEP is doing to ensure the 76 billion eggs our members produce each year in the U.S. are high quality and safe for consumers.

Regulatory Overview

UEP has a history of working with the U.S. Food and Drug Administration (FDA) on egg safety initiatives to enhance the safety of eggs produced in this country, which includes providing comments and input on the Egg Safety Final Rule and guidance documents associated with it. On July 9, 2010, FDA began implementing the regulation, which was designed to enhance egg safety by requiring measures to both prevent the bacterium Salmonella Enteritidis (SE) from contaminating eggs on the farm and reduce further growth during storage and transportation. The Egg Safety Rule requires that farmers take certain preventive steps while producing eggs on the farm and mandates refrigeration during storage and transportation to retailers and other customers.

The U.S. Centers for Disease Control and Prevention has determined Salmonella can lead to egg-related illnesses that present serious challenges to public health, with infected consumers suffering mild to severe gastrointestinal illness, short-term or chronic arthritis and even death in extreme cases. FDA estimates that the prescribed preventive actions could reduce egg-related SE cases by nearly 60 percent. Virtually all egg producers with 3,000 or more egg-laying hens are subject to the requirements, assuming their shell eggs are not pasteurized or treated in a similar manner.

The Egg Safety Final Rule requires extensive written planning, biosecurity measures, pest control, sanitation, training, record keeping, safe handling, supply chain management and environmental and product testing at prescribed intervals deemed necessary by FDA to prevent and control the hazard of SE. Prior to the finalization of the Egg Safety Rule, many farmers were already conducting activities to reduce SE contamination during production and storage through existing programs. FDA issued draft guidance in a Q&A format in August 2012 to increase education about preventing SE in shell eggs and reducing foodborne illnesses. This education initiative is part of FDA’s ongoing effort to ensure egg producers comply with the Egg Safety Rule.

While the Egg Safety Rule is relatively new, egg producers have been regulated under a variety of statutes and by several federal, state and local agencies for decades. Refrigeration, a part of the new rule, has actually been required of shell eggs held for retail distribution by FDA since 2000 (21 C.F.R. 115.50). Additionally, shell eggs held at retail establishments must be stored and displayed at an ambient temperature of 45 °F or less.

FDA has required safe handling instructions to appear on all egg cartons since 2000. The requirement aims to ensure that consumers are aware of the need to refrigerate and cook eggs (21 C.F.R. 101.17). Specifically, packaging must include the following language: “SAFE HANDLING INSTRUCTIONS: to prevent illness from bacteria: keep eggs refrigerated, cook eggs until yolks are firm, and cook foods containing eggs thoroughly.” UEP recommended these control measures and supported FDA through the implementation of both refrigeration and safe handling regulations.

Egg producers have also participated in a significant inspection program since the 1970s. The Egg Products Inspection Act mandates that shell egg plants be inspected quarterly by the U.S. Department of Agriculture’s Agricultural Marketing Service (USDA AMS). These AMS inspectors verify that disposal of restricted eggs (those falling into certain categories such as cracked, checked or dirty eggs) is done in accordance with regulations.

Virtually every state in the nation has laws governing egg safety as well—most introduced long before the FDA Egg Safety Final Rule. Many states established Egg Quality Assurance Programs (EQAPs) that were the model for this federal regulation. These guidelines impose requirements similar to or more stringent than those eventually incorporated into the latest FDA rule. EQAP compliance was theoretically voluntary, but consumer demand led to widespread, if not universal, egg farmer participation in a number of states. Some state EQAPs have expanded in recent years to include mandatory vaccination, environmental testing of chick paper and end-of-lay environmental swabs.

Finally, most egg producers currently operate under private sector, third-party-audited, quality assurance and food safety programs approved by the Global Food Safety Initiative. Examples include Safe Quality Food and the UEP’s recently expanded 5-Star Total Quality Assurance Program, which will be detailed later. Retail and foodservice customers are increasingly requiring their suppliers to implement these standards, which are often more specific and demanding than the FDA Egg Safety Rule.

What’s Next: The California Egg Rule

We are already moving rapidly through 2014, leaving egg producers (and other agricultural sectors) less than a year to comply with California’s Prevention of Farm Animal Cruelty Act (“Prop 2”), passed on November 4, 2008. The law requires a range of new animal welfare standards, most notably, that calves raised for veal, egg-laying hens and pregnant pigs can only be confined in systems that allow them to stand up, lie down, fully extend their limbs and turn around without impediment. Transportation, rodeos, fairs, 4-H programs, lawful slaughter, research and veterinary purposes received exemptions. Violation of the law carries misdemeanor penalties and a fine not to exceed $1,000 and/or imprisonment for up to 180 days.

Although specific cage size requirements were not included in the initial ballot initiative, industry experts predict hens will require twice the space currently stipulated in various standards. The California Department of Food and Agriculture developed the California egg safety rule (officially the Shell Egg Food Safety regulation) to address cage size and stocking density. The rule also sets forth testing and vaccination protocols to reduce instances of SE. Numerous testing protocols are accepted by industry best practices, but California requires that one paper for every 10 boxes of chicks be evaluated for SE. According to Rule Title 3, Section 1350, the California Animal Health and Food Safety Laboratory plans to accept three specimen types:

1. Chick papers that are swabbed with premoistened (double-strength skim milk or commercially available evaporated milk) 3×3 gauze pads at the farm after the chicks have been removed. One gauze pad is rubbed across the surface of the five papers and placed into a sterile plastic bag. After collection of up to 10 papers (two gauze pads pooled), add approximately 15–30 mL of double-strength skim milk and deliver to a laboratory within 48 hours after collection. Samples may be frozen if unable to deliver to a laboratory within 48 hours.

2. Portions of chick papers totaling 25 g should be cut out using disinfected scissors or torn out with sterile gloves, pooled in a sterile container and delivered to the laboratory from the farm.

3. Chick papers (one paper for every 10 boxes of chicks) are removed at the farm and placed into a clean plastic trash bag and submitted to the laboratory within 48 hours of collection. Samples submitted by this method will be charged an additional processing fee, and only samples from one producer will be set up per day (first come, first served, unless special arrangements are made in advance).

The California Shell Egg Food Safety rule also specifies that producers must complete “End of Production Testing” 2 to 4 weeks before the end of production. The tests should include a “minimum of sixteen manure swabs per flock that can be pooled in four swabs per bag.” This will enable producers to have a final assessment of the flock prior to the end of production. In the very rare event of a positive swab, the facility then has the opportunity to complete a hygienic restoration in place of standard cleaning and disinfecting procedures.

Rule Title 3, Section 1350 also specifies SE vaccination program requirements. Egg producers are required to deploy a protocol that includes at least two attenuated live vaccinations and one killed or inactivated vaccination, or an equivalent program approved by the California Department of Food and Agriculture. Vaccination has become a very effective component utilized by producers as part of SE control in the U.S. egg industry.

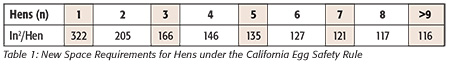

The statute became effective for chicks placed after July 1, 2013, for swabbing and vaccination requirements, with farmers having until January 1, 2015, to meet the new space requirements (Table 1).

The statute became effective for chicks placed after July 1, 2013, for swabbing and vaccination requirements, with farmers having until January 1, 2015, to meet the new space requirements (Table 1).

California’s statute took on national prominence when then-Governor Arnold Schwarzenegger signed legislation in 2010 adding a new requirement that all eggs sold into the state meet the new standards. Californians consume a lot of eggs—

9 billion in 2012 to be exact (directly or in foods made with eggs). But only 55 percent of those eggs consumed were produced in California, requiring numerous farmers outside the state to change their production standards to remain in the marketplace under the law signed by Governor Schwarzenegger.

Egg producers (and other farmers) were in limbo through late 2013 and into the new year, holding off on making significant financial investments while the United States Congress debated the Federal Agriculture Reform and Risk Management Act (“Farm Bill”) and King Amendment. Representative Steve King (R-Iowa) was able to include a prohibition on states imposing conditions on another state’s production of agricultural goods in the House version of the proposed Farm Bill, which was ultimately not included in the final legislation passed by Congress in early 2014. Subsequently, Missouri’s attorney general filed a lawsuit in federal court over the California law, with other states expected to join in. The debate has evolved from egg and other animal food production to one about interstate commerce and the federal government’s constitutional ability to regulate it. The outcome will impact a score of food and animal welfare laws. Farmers need clarity on whether California’s law will become a mandate for any producer selling eggs into that state.

Consumer Responsibility

Egg producers are primarily responsible for ensuring a safe egg supply in the marketplace, but consumers take the wheel once eggs leave the store. Shell eggs may contain SE or other microorganisms and should always be handled safely, promptly refrigerated and thoroughly cooked to ensure illness is avoided. USDA instructions for safe handling are simple and effective:

• Wash hands, utensils, equipment and work areas with hot, soapy water before and after contact with eggs and egg-containing foods

• Keep raw eggs in their original carton at 45 °F or below and consume within 5 weeks of purchase

• Ensure eggs do not remain outside a refrigerator for more than 2 hours in moderate environments or 30 minutes to 1 hour when 85 °F or hotter

• Remove only the number of eggs needed and then return the carton to the refrigerator

• Use a thermometer that measures the internal temperature of cooked foods when possible to ensure eggs are thoroughly cooked (160 °F for mixed egg dishes)

• Poached and fried eggs should be cooked until the white is completely firm and the yolk is thickened, and scrambled eggs should be cooked until there are no visible liquids

• Leftover hard-cooked eggs should always remain refrigerated in their shells and used within a week

• Resist the urge to taste mixtures containing eggs before they cook (i.e., cookie dough or cake batter)

• Place hot foods into shallow containers and refrigerate, allowing them to cool completely if eggs were included and the dish will not be served immediately after preparation

Egg Industry Leadership

Clearly, America’s egg farmers (and other food producers) face myriad regulations and guidelines to ensure food safety and animal welfare. The UEP created its own safety program to provide farmers with a clear set of science-based, socially conscious industry best practices. The egg industry, led by UEP, has made a concerted effort since 1988 to reduce SE. Key steps in this initiative include the following:

• Establishing an SE Task Force

• Calling for breeder testing through the National Poultry Improvement Plan

• Proposing and assisting with the National Refrigeration Law

• Recommending liquid pasteurized egg products be used in foodservice and institutional settings

• Developing the UEP 5-Star Total Quality Assurance Program

• Partnering with state and federal regulators by testifying and providing comments on various standards

Providing safe, quality food for consumers is a top priority for egg producers across the United States. That’s why the industry took the unprecedented step of creating the UEP voluntary 5-Star Total Quality Assurance Food Safety Program in 1994. The program provides egg producers nationwide with a proactive way of monitoring and controlling SE on-farm. The 5-Star goes beyond FDA Egg Safety Rule requirements and gives egg producers a comprehensive, dependable food safety program from the farm to processing plant. The 5-Star Egg Safety Program covers the following topics:

• Chick procurement

• Biosecurity

• Integrated pest management

• Cleaning and disinfection of poultry houses

• Refrigeration

• Environmental and egg testing

• Vaccination

• Feed management

• Traceability

• Laboratory standards

• Processing plant sanitation

This patchwork of regulations, guidelines and industry best practices, while complex, should fortify consumer confidence in the safety of eggs consumed in restaurants or purchased in grocery stores. Perhaps that’s why, as demonstrated by more than a decade of industry research, consumers regularly place egg producers in the top echelon of food safety and animal welfare. The UEP and its member producers take pride in developing and implementing new and innovative programs and processes to improve the safety and quality of eggs sold in this country. Consumers enjoy an abundant and safe egg supply largely due in part to the proactive measures taken by the U.S. egg industry. Universal application of uniform state and federal regulatory and compliance measures helps ensure that these processes effectively protect public health. As new science emerges and new food safety practices become available, the egg industry will continue to provide a safe and nutritious product that encompasses all aspects of production from farm to fork.

.jpg) Oscar Garrison is director of food safety programs at United Egg Producers. Prior to this venture, he had a regulatory-based career for over 19 years at the Georgia Department of Agriculture, where he held the executive positions of food safety division director and assistant commissioner of consumer protection. Additionally, he is the past president of the Association of Food and Drug Officials, where he led the national organization’s efforts to promote an integrated food safety system. He is also the past president of the Georgia Association of Food Protection, an executive committee member of the Partnership for Food Protection, food safety liaison to the National Association of State Departments of Agriculture and a member of the National Integrated Food Safety System Task Force.

Oscar Garrison is director of food safety programs at United Egg Producers. Prior to this venture, he had a regulatory-based career for over 19 years at the Georgia Department of Agriculture, where he held the executive positions of food safety division director and assistant commissioner of consumer protection. Additionally, he is the past president of the Association of Food and Drug Officials, where he led the national organization’s efforts to promote an integrated food safety system. He is also the past president of the Georgia Association of Food Protection, an executive committee member of the Partnership for Food Protection, food safety liaison to the National Association of State Departments of Agriculture and a member of the National Integrated Food Safety System Task Force.

p>