From Standards to Strategy: Utilizing Benchmarking and Lean Six Sigma for Excellence

The integration of Lean Six Sigma and benchmarking methodologies offers a robust framework for optimizing process manufacturing

In today's fiercely competitive landscape, achieving and sustaining excellence in process manufacturing, particularly in sectors like the food manufacturing industry, is imperative for organizations striving for long-term success. With consumers demanding higher-quality products, faster delivery times, and lower costs, food manufacturers face relentless pressure to optimize their operations continually while maintaining strict compliance with safety and regulatory standards. This constant drive for operational excellence necessitates the adoption of robust methodologies that can effectively address these challenges. Two such methodologies have emerged as cornerstones in this pursuit: Lean Six Sigma and benchmarking. Individually, they offer formidable tools for process improvement, but when integrated, their synergy becomes a potent force for driving performance enhancement and maintaining a competitive edge.

The Framework of Lean Six Sigma

Lean Six Sigma represents the integration of two distinct yet complementary methodologies, each contributing a unique approach to process optimization. Lean principles focus on identifying and eliminating waste—defined as any activity that does not add value from the customer's perspective. By streamlining workflows and reducing non-value-added tasks, Lean enhances operational efficiency. In contrast, Six Sigma prioritizes the reduction of process variability to improve quality and consistency. When combined, these methodologies form Lean Six Sigma, a comprehensive framework that drives continuous improvement, operational excellence, and sustainable performance enhancements across organizations.

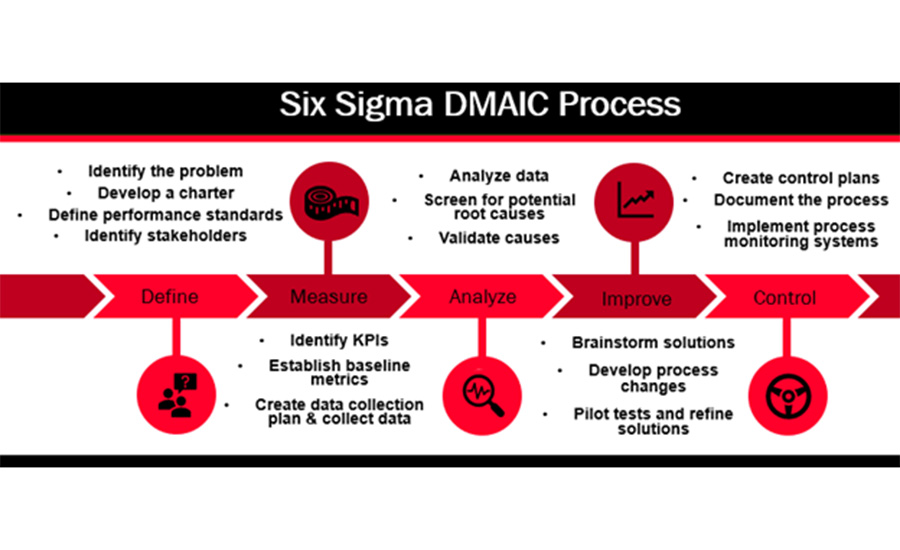

Even organizations or project teams that are not formally trained in Lean Six Sigma may unknowingly apply its principles. A prime example is the DMAIC framework1—an iterative, data-driven process improvement cycle with five stages: Define, Measure, Analyze, Improve, and Control (Figure 1). For instance, in the initiation of a project, creating a thorough project charter that documents inputs, outputs, objectives, constraints, resources, and timelines exemplifies the 'Define' phase of DMAIC. Engaging stakeholders from various departments in this process ensures clarity, alignment, and shared ownership, laying a strong foundation for successful project execution.

Starting a new project often comes with significant challenges, particularly when it requires substantial resources such as human capital, financial investment, and materials. By beginning with a meticulously crafted project charter, organizations can achieve alignment, reduce the risk of allocating non-value-added resources, and address potential pitfalls early on. While unforeseen obstacles may arise, clearly defining objectives, managing expectations, and establishing the project's primary goals at the outset are critical. Without these efforts, projects may suffer from misaligned scope, insufficient resources, or inadequate time and budget, ultimately jeopardizing success.

Exploring Benchmarking: Key Concepts and Practices

Benchmarking is a powerful strategy for performance enhancement, enabling organizations to assess their performance, processes, or practices by comparing them to industry leaders or established standards. Defined by the Oxford English Dictionary as "evaluating or checking [something] by comparison with a standard," benchmarking identifies performance gaps and highlights best practices that can improve outcomes and competitiveness. By leveraging benchmarking, organizations gain valuable insights that complement Lean Six Sigma efforts, drive targeted improvements, and align processes with industry standards.

The benchmarking process typically involves key steps to ensure that product or process improvements stay on course. These steps include:

- Understanding the benefits of benchmarking

- Identifying what or whom to benchmark against

- Documenting current processes

- Selecting suitable metrics

- Analyzing results to drive improvement

- Creating an improvement plan

- Implementing changes to sustain the improvements.

For example, a specialty food manufacturer aiming to enhance the consistency of its spice blends might benchmark its blending process against the best internal practices or against the precision standards of a leading flavor house. Organizations must also decide whether to pursue internal or external benchmarking based on the specific aspect under scrutiny. External benchmarking provides broader perspectives by comparing processes or strategies to industry leaders. However, in industries characterized by innovation or market leadership, where external benchmarks may be challenging to find, internal benchmarking becomes essential.

Internal benchmarking often relies on tools such as value stream mapping to optimize processes, takt time to measure throughput, and other straightforward metrics like downtime or right first time (RFT). It is critical to avoid collecting excessive or unnecessary data, focusing instead on metrics that add measurable value to the process. Lean Six Sigma methodologies are invaluable in determining what metrics are worth measuring, emphasizing features or aspects that align with organizational goals.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

For example, an organization aiming to improve the overall equipment efficiency (OEE) of its lowest-performing machine might begin by benchmarking against its top-performing machine internally or by conducting external comparisons with industry standards. The first step would involve documenting the current processes affecting the OEE, such as cleaning, inspecting, and lubricating (CIL) routines; quality inspections; or preventive maintenance procedures. Relevant metrics, such as downtime duration, reasons for downtime, and the number of defective products, would be identified and tracked with precision to ensure confident decision-making.

Once data is collected, it must be thoroughly analyzed to uncover improvement opportunities. Based on this analysis, the organization would create a detailed improvement plan, including clear objectives, timelines, and necessary resources. Regular evaluations are conducted to assess progress, address challenges, and ensure that the improvements are sustained over time. This structured approach to benchmarking enhances process optimization and aligns with Lean Six Sigma principles, fostering continuous improvement and operational excellence.

Considerations for Improvement Initiatives

Before initiating any improvement endeavor, whether using benchmarking or Lean Six Sigma methodologies, it is crucial to grasp the purpose behind altering your product or process. If the endeavor will not yield an increase in profit, cost savings, improved efficiency, or increased quality, then it will likely not be of value. For example, a company might find that its sales volume decreased tremendously in the last month. In response, it may want to leverage these methodologies to improve its product and increase sales (profit).

Once the "why" has been established, it is essential to pinpoint the specific aspect or feature of the product (or process) on which the company aims to focus. Failing to narrow the scope to a precise goal can prolong the project and hinder its success. There are many ways to pinpoint the specific aspects of the product to prioritize. Utilizing the 'voice of the customer' (VOC) emerges as one of the most effective approaches to home in on your 'critical to X' characteristic. Typically, this serves as the catalyst prompting enhancements to a product or process. The VOC can be obtained through methods such as client meetings, customer service reports, interviews, direct observations, customer complaints, etc.

While the adage "don't fix what isn't broken" can apply to situations such as these, in the realm of continuous improvement, a company might discover that previously effective practices and processes are no longer beneficial means of proper efficiency or throughput. A company might also find that customer expectations or wants have changed and the product that used to be a top seller is no longer maintaining its performance in the market. In this case, the company might decide to benchmark against external products by analyzing market positions and VOC to determine which aspects or features to prioritize. At this level, competition with other companies intensifies. While benchmarking is just one tool for optimization, continuous improvement is essential for companies to remain relevant. With the ever-evolving expectations of modern consumers, it is crucial to challenge the status quo while considering the VOC to meet these expectations effectively.

In addition to VOC, cost savings and budgeting are very important factors to keep in mind when considering any sort of change to your manufacturing process or raw materials for the finished goods. Cost savings and customer feedback must go hand in hand! Customer feedback allows you to determine 'critical to X' characteristics, so that when developing a cost savings/budgeting method, those characteristics are still maintained. For example, if a company produces gourmet sauces and it is determined from the VOC that customers are drawn to the rich, authentic flavor, it is critical that costs are not cut to the point that the flavor quality is compromised.

Driving the Project Charter with Lean Six Sigma and Benchmarking

Incorporating benchmarking into the Lean Six Sigma methodology within a project charter can be challenging, but with the right approach, it becomes a powerful tool for driving continuous improvement.

The first crucial step is to define the company's goals with clarity and precision. By narrowing down exactly what the organization hopes to achieve, you will set a clear direction for the project. As a key stakeholder, you must take the lead in championing the project's progress, ensuring it remains focused and preventing 'scope creep.' Scope creep can easily derail the entire project, particularly if the team starts addressing issues that fall outside of the defined objectives. This diversion often leads to extended timelines and can result in an incomplete or delayed project. To avoid this, the project charter needs to explicitly outline the end goal by providing a framework that keeps the team focused on achieving the primary objectives. Benchmarking, whether internal or external, should be integrated into the project's foundation before work begins. It serves as a critical driver of continuous improvement throughout the process. Benchmarking helps organizations compare their current practices to industry standards or best-in-class performance, pinpointing areas that need improvement.

This exercise could involve various elements of the process, such as evaluating the sourcing of raw materials or analyzing weight distribution from a depositor in the production line. By identifying these areas early on, benchmarking ensures that your processes remain aligned with best practices and targeted goals. The success of any project hinges on the effective use of data, particularly when it comes to identifying leading and lagging indicators. Leading indicators are proactive measures that give insights into what is likely to happen in the future, allowing the organization to act before problems arise. For example, in a production setting, leading indicators might include machine downtime, maintenance frequency, or supplier delivery performance. These indicators allow a company to anticipate potential issues, adjust workflows, and refine processes before they affect the final results.

In contrast, lagging indicators measure past performance, such as sales revenue, profit margins, or customer satisfaction scores. While lagging indicators are valuable for assessing overall success, they offer little insight into what can be done to influence future outcomes. By identifying leading indicators, organizations can create a proactive strategy to ensure that future results align with their goals, ultimately achieving improved efficiency, quality, and competitiveness.

Measuring Improvement Capability and Sustainability

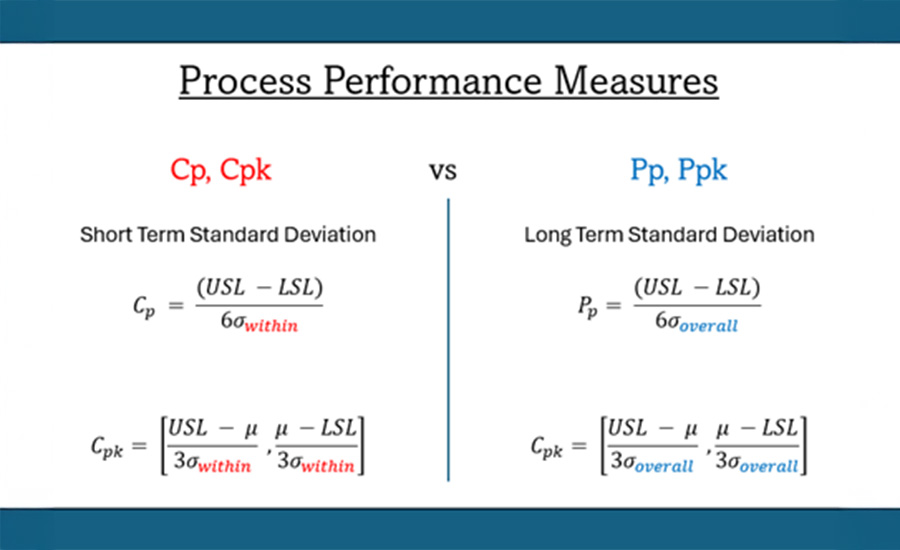

Once the metrics for features are established, calculations such as Cpk (Process Capability Index) and Ppk (Process Performance Index) can assess the sustainability of an improvement project.2 Cpk is defined as a "statistical tool used in Statistical Process Control (SPC) to assess the performance and capability of a process."3 Utilizing this tool offers valuable insights into a process' capability to meet specifications and deliver consistent outcomes. Cpk is calculated using the formula shown in Figure 2.

Like Cpk, a process with a Ppk of 1.33 or higher is generally considered capable of consistently meeting specifications. Lower values indicate greater variability and a higher likelihood of producing out-of-spec products, suggesting the need for process improvement. Values closer to zero reflect poor performance and an inability to meet specifications reliably. Higher Cpk and Ppk values indicate better process capability and performance, bringing the process closer to Six Sigma quality, which is characterized by minimal defects and high efficiency.

Ppk and Cpk are both used to assess how well a process meets specification limits, but they measure different aspects. Cpk evaluates a process' potential capability based on within-subgroup (i.e., short-term) variability, assuming the process is stable and under control. In contrast, Ppk measures the actual performance of the process over time, using overall (i.e., long-term) variability, and includes all sources of variation.

Ideally, Cpk and Ppk values should be similar if the process is stable. A significant difference between them suggests the presence of special cause variation, indicating that the process may be out of control. In such cases, predictions about process performance or nonconformance rates are unreliable. Before calculating true process capability, it is essential to first eliminate special causes and ensure the process is stable, so that capability reflects only common cause variation.

Bringing it All Together

The integration of Lean Six Sigma and benchmarking methodologies offers a robust framework for optimizing process manufacturing. By embracing Lean Six Sigma principles, such as DMAIC, organizations can identify and prioritize critical aspects of their products or processes. Benchmarking, whether internal or external, provides valuable insights by comparing these aspects against industry standards or leaders. The synergy of these methodologies creates a powerful tool for driving improved performance. However, it is crucial to first consider the purpose behind the improvement. Without this consideration, critical attributes of the product or process could be unintentionally sacrificed.

When undertaken for the right reasons, these methodologies can guide a company through its improvement journey, ensuring it remains agile and responsive to changing demands. Once the "why" has been established and the project scope has been identified, various tools can be leveraged to evaluate capability and sustainability. Tools such as Cpk and Ppk are instrumental in this evaluation. As the competitive landscape continues to intensify, a commitment to continuous improvement through these methodologies and the strategic application of these tools will be paramount in sustaining long-term success and maintaining a competitive edge.

References

- Go Lean Six Sigma. "DMAIC—The 5 Phases of Lean Six Sigma." January 24, 2025. https://goleansixsigma.com/dmaic-five-basic-phases-of-lean-six-sigma/.

- Quality Gurus. "Process Capability and Performance (Cp, Cpk, Pp, Ppk, Cpm)." https://www.qualitygurus.com/process-capability-and-performance-cp-cpk-pp-ppk-cpm/.

- Croft, D. "Guide: Statistical Process Control (SPC)." Learn Lean Six Sigma. https://www.learnleansigma.com/guides/statistical-process-control-spc/.

Michael Ciepiela is Vice President of Quality and Continuous Improvement at Southern Specialties. He brings over a decade of diverse experience in the food and beverage industry, along with experience in the pharmaceutical sector, specializing in quality assurance and food safety. Throughout his career, he has excelled in multi-site implementation and adherence to GFSI requirements and regulations. Michael has also been instrumental in promoting and educating Lean Six Sigma principles in fast-paced, cross-departmental settings. As a recognized thought leader, Michael frequently speaks at national conferences. He is also a senior member of the American Society for Quality (ASQ). He holds a bachelor's degree in Biology from Alfred University and a Six Sigma Master Black Belt from Villanova University.

Haley Bratton is a supply chain professional with experience in continuous improvement, project management, and manufacturing operations within the consumer packaged goods industry. She has successfully led numerous continuous improvement projects aimed at enhancing efficiency and minimizing process waste. Additionally, she has developed a profound understanding of Lean Six Sigma principles, mentoring others in these methodologies. She received her B.B.A. degree in Business Administration from the University of Tennessee with a Major in Logistics, Materials, Supply Chain Management, and a Minor in Business Analytics and Statistics.