Intervention Controls

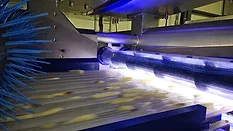

Intervention controls involve the addition of control measures into a process to reduce and, ultimately, prevent or eliminate food safety risks.

Articles

More ArticlesNever miss the latest news and trends driving the food safety industry

Newsletters | Website | eMagazine

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing