ColloidTek Collo Analyzer Offers Real-Time Liquid Process Quality Monitoring

Image provided by ColloidTek

Image provided by ColloidTek Collo Analyzer

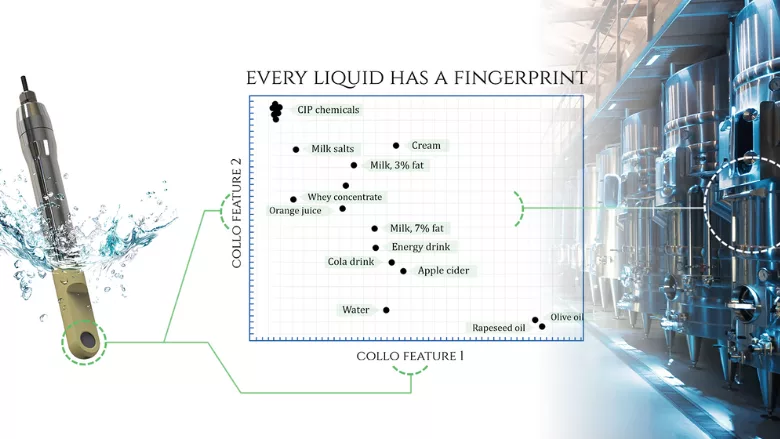

ColloidTek’s Collo Analyzer is a new method for real-time liquid process quality monitoring, offering significant benefits for the food and beverage manufacturing industry. Based on electric and magnetic (EMF) sensors and machine learning, the technology detects various contaminants and identifies potential risks in liquid processing with a single real-time measurement and instant, inline analysis. The novel solution provides food and beverage manufacturers with comprehensive information about the quality of their products at any stage of production, ensuring the safety, quality, and correct taste of the end product.

In liquid processing, like in the dairy industry, efficient quality control is critical, as it is essential to confirm that there are no contaminants in milk batches, such as cleaning chemical residues. Traditionally, collecting samples for laboratory analysis has been time-consuming, leading to delays and potential product quality risks. In addition to the logistics of transporting the sample to the laboratory, manufacturers can expect to wait days for results. Meanwhile, milk has often already been processed into end products, and if sample testing finds a batch to be potentially hazardous, the implications may be hugely detrimental.

With the rise of advanced technologies, comprehensive quality control is easier and cheaper to achieve than ever before. Collo Liquid Analyzer is an efficient and reliable method to ensure companies meet their quality and safety requirements. Unlike traditional laboratory testing, the Collo Analyzer offers instant, inline analysis of the quality of liquid.

Quality control in the food and beverage industry is typically based on collecting samples and sending them to the laboratory, where the results arrive after several days or even weeks. In some cases, there are not any tests available for detecting certain risks. With Collo, a test takes two seconds. The measurement can be done onsite manually by dipping the sensor into the product, or in the line, straight from the pipe. There is no need to send samples anywhere; the results are instantly available. This is made possible by EMF technology and the advanced algorithms that power the analyzer, which is the only one of its kind in the food and beverage industry.

Due to increased consumer demand, companies must consistently monitor the quality of higher production volumes and larger plant-based product portfolios. While a diverse portfolio can offer market advantages, it also introduces a host of complexities and challenges for quality control. Larger product portfolios lead to increased numbers of quality control tests, and each product variant may have unique specifications, ingredients, and quality standards.

Most currently available systems can only analyze liquids with specific viscosity, transparency, or other characteristics. This often means several different analyzers and sensors are needed at each testing point, which leads to a complex multi-sensor system that is laborious to maintain and still does not arm manufacturers with enough information for comprehensive quality control. As Collo Analyzer can be used with thick liquids, like honey, as well as transparent or non-conductive liquids, such as vodka or milk protein concentrate, only one device is required to measure the quality of all the liquids in the production.

The solution can simultaneously detect multiple risks or deviations, simplifying complex quality control processes by replacing other tests and covering aspects of safety and quality that no other analyzer can manage. The novel technology not only accelerates the quality control process, but also empowers manufacturers to take immediate corrective actions when deviations are detected, reducing the risk of costly recalls and ensuring that every batch of products meets the highest quality and safety standards.

ColloidTek: www.collo.fi

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

.webp?t=1721343192)