Whenever anyone one of us eats or drinks something, we have certain expectations. The product should look, smell and taste as expected. But what happens when something unexpected occurs, such as finding a foreign material in the food? The fortunate ones discover the "the surprise" before they put the food into their mouth. The unfortunate? Well, everyone has heard the old joke, "What's worse than finding a worm in your apple? Half a worm."

Foreign materials in foods are a real concern to the food processor, not only in terms of the consumer complaints that arise, but as an important factor in the effective implementation of the company's food safety program, particularly the Hazard Analysis Critical Control (HACCP) system. Consuming half a worm might nauseate the consumer, but it is not likely to result in surgical intervention as would the ingestion of a piece of glass or metal. In other words, not all extraneous materials render a food unsafe, but it behooves us all to keep foreign materials out of foods both consumer to prevent dissatisfaction, which can lead to adverse publicity and lost sales, and to prevent a food safety hazard as identified in regulatory compliance policy. Let's examine the following questions: What are the potential physical hazards in foods? How might these materials gain access to the processing system or the product? How can physical hazards be detected and removed?

Defining Physical Hazards

The U.S. Department of Agriculture's Food Safety and Inspection Service (USDA FSIS) held a two-day technical conference in September 2002 to discuss foreign material contaminants, prerequisite programs and validation issues. While FSIS administers the Federal Meat Inspection Act, the Poultry Products Inspection Act and the Egg Products Inspection Act, the group of presenters touched on many aspects of extraneous materials hazards of concern to most types of food processing and handling operations. Much discussion centered on how foreign materials need to be addressed in the HACCP plan and through Standard Sanitation Operating Procedures (SSOPs) and prerequisite programs. Here's what some of these food safety experts reported:

• About 80% of foreign body ingestions occur in the pediatric age group, or children below the age of three. It is estimated through a variety of reports and case studies that anywhere from 1% to 5% of foreign bodies ingested will result in some injury. A classic and very sad example of foreign materials and children occurred within the past few years. A gel-based candy was taken off the market after causing choking deaths in young children. This candy was supposed to melt in the mouth. Instead, it lodged in the throat and stayed there.

• According to a passive surveillance system through which FSIS receives consumer complaints on agency-inspected product (i.e., representative of only what consumers or state health departments have called in to report), of 1,309 complaints reported from 2001 to September 2002, 331 were related to foreign materials (25%). About 6% of those cases resulted in injury. The most common materials were identified as metal, glass and plastic.

Almost all HACCP classes include a discussion of potential hazards in foods. The focus of this discussion is usually the biological hazards, which because they are the most important in terms of public health makes complete sense. The lecturer would be remiss if physical hazards were ignored, however. Before entering into a discussion of physical hazards, let's review some of the basics.

Food processors are mandated by law to produce safe foods. A safe food may be defined as a product which contains no physical, chemical or microbial organisms or by-products of those organisms which if consumed by man will result in illness, injury, or death (an unacceptable consumer health risk). The definition purposely does not use the term contaminants because many of the potential hazards in food that HACCP programs are designed to address are typicallly found in or on the food. It is their concentration, numbers or size that create potential safety problems. We must, therefore, understand what constitutes a hazard. A food hazard may be defined as:

Any biological, chemical, or physical property that may cause an unacceptable consumer health risk.

In terms of physical hazards in foods, the following are pertinent government definitions:

• The Food Drug and Cosmetic Act, 402(a)(3&4): "Adulterated food consists in whole or in part of any filthy, putrid, or decomposed substance or is otherwise unfit for food" or has "prepared packed or held under insanitary conditions whereby it may have become contaminated with filth, or whereby it may have been rendered injurious to health."

• Good Manufacturing Practice (GMP) 110.80(b)(8): "Effective measures shall be taken to protect against the inclusion of metal or other extraneous materials in food. Compliance with this requirement may be accomplished by using sieves, traps, magnets, electronic metal detectors, or other suitable effective means."

In addition to these regulatory definitions, government agencies have determined that characteristics of the foreign material contaminants also are important when assessing how hazardous such inclusions. For example, the U.S. Food and Drug Administration (FDA) has been monitoring injuries resulting from foreign materials since 1972. Over a 25-year period, the agency evaluated 190 cases involving hard or sharp foreign materials in foods. The agency has developed criteria for determining whether a product is adulterated and could cause injury. Only hard or sharp foreign objects that measured 7 mm to 25 mm were determined to be hazardous. Objects less than 7 mm were determined to be too small to cause injury and those greater than 25 mm were so large that the agency felt that there was little chance of a consumer eating the food. Clearly, other characteristics such as the concentration and number of inclusions also have an impact on whether the physical contaminant is a food safety issue or a consumer perception issue.

When defining physical hazards, the processor also mustlook beyond the regulatory definitions to his own processes and systems. When conducting a hazard analysis, for example, the HACCP team looks at potential hazards that could realistically cause illness or injury. The consideration of what consitutes unwanted foreign materials inclusions will vary from operation to operation. Processors need to look at what is coming in, how the product is processed and the form of the end product as part of their hazard analysis.

Similarly, another source that may be used for determining whether something is or is not a hazard is consumer complaint records. If a company has been operating for an extended period of time, these records can support a conclusion that a particular foreign material is not a realistic hazard. One also needs to be realistic in these assessments. Single-strength juices and beverages are not likely to have foreign materials in them, especially if processed through a unit such as a plate heat exchanger. Years ago, I looked into a complaint that a 46-ounce can of juice contained a banana slug. There simply was no way that such a creature could have gone through the process. Such an event could only be caused by employee sabotage or consumer fraud.

The bottom line is that each and every operation needs to evaluate whether foreign materials are a realistic hazard, and if so, how can these will be prevented or controlled. Do you need a CCP, or do you believe that the hazard(s) can be controlled through your prerequisite programs?

Sources of Foreign Materials in Foods

It is generally agreed that there are five basic sources of foreign materials in foods. The question still remains as to whether foreign materials from these sources would be construed as potential hazards. These five sources are:

1. Inadvertent from the field (stones, metal, insects, undesirable vegetable matter such as thorns or wood, dirt, or small animals).

2. Inadvertent resulting from processing and handling (bone, glass, metal, wood, nuts, bolts, screening, cloth, grease, paint chips, rust, and so on).

3. Materials entering the food during distribution, such as insects, metal, dirt, or stones.

4. Materials intentionally placed in food (employee sabotage).

5. Miscellaneous materials, such as struvite and other materials in this class.

The unit operations in processing plants should be designed to remove or eliminate the physical hazards described under the first two scenarios. Operations that process raw agricultural commodities, such as fruits and vegetables, or grains and seeds, would be remiss if they did not build such cleaning operations into their lines. In the U.S., most crops are mechanically harvested. Mechanical harvesters have one major problem in that they often collect more than just the product. Stones, wire, and small birds, mammals or reptiles can be collected by the harvesters. I once watched a four-foot-long snake drop out of a load of green beans being deposited in a washer. The workers went one way and the snake the other. This is one of the reasons that processors include destoners, air cleaners, magnets, screens and washers in their lines.

Another reason is economics. Removal of stones, scrap metal or other materials protects your investment--the equipment--from damage. Failure to remove a stone from a product before it enters a chopper or slicer could damage the unit, and create a secondary problem: metal in the system. Grain processors and manufacturers of flour utilize screens throughout the process. The screens help them sift and size product, but they also remove undesirable foreign materials. Cleaning is an integral part of processing agricultural commodities.

Inadvertent contaminants from the processing operations may be another potential source of foreign materials. This is one of the reasons that preventive maintenance is considered a HACCP prerequisite. Properly maintained equipment and lines usually do not cause problems.

The next question is whether there is a potential for contamination during distribution and storage. Distribution and storage practices and in-store handling practices should control and/or be designed to prevent the finished food product from being contaminated or affected. Once the container is sealed, the chances for physical contamination are greatly reduced, particularly if one is dealing with metal, glass, or one of the thermoplastics used for hermetically-sealed foods.

In addition, food protection is one of the primary functions of the package. All packages should be designed to prevent tampering or to be tamper-evident. In fact, there is little chance of contamination of any packaged food becoming contaminated once it is in the package. On rare occasions, if grains, flours, dried fruits or other materials packaged in paper or cardboard are stored or held in an area that is infested with insects or rodents, the pests can get into the containers. Examination of infested containers will let an examiner know whether the insects came from the inside or outside. For example, experts can tell whether an insect chewed his way in or out. The greatest concern with contamination during distribution and storage is with bulk products. This also is an area where food security issues need to be addressed. There is a great deal of concern that bulk materials could be a target for attack.

Foreign material contamination resulting from employee sabotage is more insidious and is very difficult to monitor. It is quite amazing what unscrupulous employees have placed in containers in the past. Controlling employee sabotage is a function of good management and proper employee education. Implementation of an all-encompassing quality assurance system whereby employees are educated on good food handling and HACCP principles makes food safety everyone's responsibility and can reduce the likelihood of this problem. Management cannot watch everything, but line workers generally know exactly what goes on. These individuals are excellent sources of information. When examining a facility, they can provide an inspector or auditor with a great deal of useful information, provided he or she can gain their confidence.

When conducting in-house education programs on food handling and hygiene, don't forget to address this issue. Let your staff know that what might seem like a "joke" or a means for a disgruntled employee to get back at the company, can adversely affect the company and maybe even their jobs. Line workers need to understand that they have a stake in their company's products and business.

Foreign Material Inclusion Detection, Removal and Verification

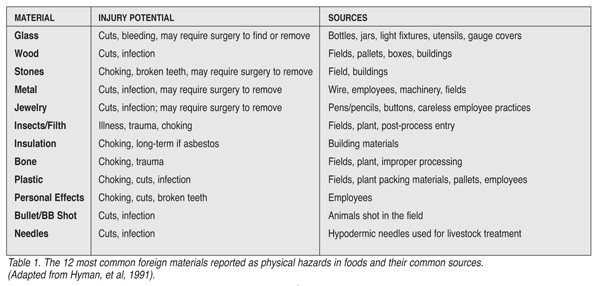

Table 1 describes "The Dirty Dozen," otherwise known as the most common foreign materials found in foods, their potential for causing injury and some sources for these materials (Table 1). Let's take a closer look at the "Dirty Dozen" and determine whether they are realistic hazards, and how a food company can go about detecting, controlling and verifying the removal of foreign materials from product.

Table 1 describes "The Dirty Dozen," otherwise known as the most common foreign materials found in foods, their potential for causing injury and some sources for these materials (Table 1). Let's take a closer look at the "Dirty Dozen" and determine whether they are realistic hazards, and how a food company can go about detecting, controlling and verifying the removal of foreign materials from product.

Metal, Bullet/BB Shot, Needles. Metal is a common industry concern. The best way to assure that metal is not an issue is good preventive maintenance. Are bolts and screws being loosened by equipment vibration? Or, didn't there used to be a bolt in that hole? Ferrous metal can be removed using magnets that can be placed in-line. If an operation uses magnets, they should be monitored to determine what they are collecting. Metal detectors are becoming more and more common in processing operations in this day and age. In some industries, especially meat processing, metal detectors are roundly considered a necessity. Why you may ask? For some perverse reason, people like shooting at cattle and many end up with pellets imbedded in the muscle. Metal detectors should find the pellets. With increased use, they are becoming more sensitive, easier to maintain and calibrate and easier to use. In fact, there are many processors and buyers who mandate that everything that they manufacture or buy pass through a metal detector. Metal detectors can detect ferrous metals ranging down to 1-2 mm in size; nonferrous metal sensitivity might be in the 2-3 mm range. Smaller pieces of metal would not be considered hazardous.

Another big concern to the livestock industry is the number of occasions that a cow or other animal will "flinch" when being given an injection causing the needle to break off below the skin. These needles or needle parts can cause great injury to a person who unwittingly consumes it, and so needle manufacturers have improved the detectability of these items, creating patented alloys that allow the metal detector to alert the processor to their presence as the food proceeds down the line.

Jewelry. Food products are not supposed to be Cracker Jacks boxes. You're not supposed to bite into your hamburger and find a "prize" that came from somebody's finger in the factory. Depending on the type of jewelry, metal detectors are useful control tools, since most jewelry is metallic and people want others to see it (why else is it worn?). Precious stones are another issue. They are not metallic, so may slip through. Sieves and screens can help remove them, as will the use of X-ray screening systems.

Stones, Wood, Insulation. These materials may cause injury. Consumers might break a tooth or cut themselves. Are they realistic hazards, however? Personally, I have never been in a plant where I felt that these were real hazards. Cleaning of incoming materials, the application of Good Manufacturing Practices (GMPs), the use of screens and sorting in process operations and the nature of the contaminants themselves tend to minimize the potential for product contamination. Insulation could be placed in the same category. The bottom line is that these materials can be controlled by the application of your HACCP prerequisite programs. If you, as a processor, are concerned about these wood or stones, take a look at your consumer complaint files. I would wager that there have been very few, if any, alleged or real complaints regarding these materials.

Glass. Perhaps the hardest potential physical inclusion to evaluate is glass. Operators need to keep it out of the plant. It is a hazard if large enough and an adulterant if small. Taking a stand that "Our process would crush all glass to an acceptably small size that reduces the hazard" is unacceptable. And, yes, I have heard this explanation.

Glass is hard to see because it is usually clear. It is sharp and will cause injury, but again, is it a realistic hazard? Processors who pack foods in glass almost always have a program in their plants addressing what should be done in the event of glass breakage. When I worked with juice-in-glass, our policy was to discard all containers within 10 feet of any glass that shattered. Containers that had been filled and sealed were washed to remove shards. Our objective was to assure that there were no shards of glass of any size in the product.

Prevention of glass contamination is one reason that regulations emphasize the importance of shielding lights. If a bulb blows or is broken, glass may fly all over. If there is any exposed product, it should be destroyed. Reconditioning or sorting to remove shards would be expensive and inefficient. Now there are instruments that can be installed "on-line" to scan for glass and other materials. These systems utilize X-rays or other sophisticated scanning tools.

Insects or Insect Parts/Filth. Is the presence of an insect in a food product a real hazard? If you eat that insect will you become sick? The answer is not really. There are many cultures where insects are considered delicacies. Psychological trauma is not considered a physical injury. So, does this mean that we should accept insect contamination in foods? The answer is no. Remember, we are in business to make money and in the food industry and this means making repeat sales. The consumer who discovers insects or insect parts in their food will probably not buy that product again. It also could mean a visit from an agency looking for insanitary operating conditions, or even worse, coverage by the media. The resulting adverse publicity can damage the company's reputation and adversely affect sales.

Good SSOPs, an effective pest control program and the use of proven insect control tools should greatly reduce contamination of foods.

Bone. Bone can injure someone, but what is ironic in some cases is that it is not considered a hazard. For example, bones in bone-in chicken are considered a normal component of the product. In products that are declared to be deboned, the presence of bones is a realistic concern. The same rationale applies to products like pitted and unpitted olives. To minimize the potential for bone contamination, most meat processors use deboned beef. As an added precaution, sausage makers often incorporate a bone removal system as part of their grinding operations.

Plastic. Plastic can be a contaminant, but it probably is not a real hazard, unless it gets into foods destined for infants. The best control for plastics (liner bags and such) is adherence to established standard operating procedures and GMPs, coupled with the use of sieves or screens. There also are companies that mandate the use of colored liner bags because any pieces of colored plastic that get into food are easier to see. Clearly, if a piece of blue or red plastic gets into products like sugar, salt or flour they would be highly visible to line workers and supervisors. Plastics will not be detected in metal detectors, but may be found by X-ray detectors. The efficacy of X-rays is one of the topics that was addressed at the recent Food Safety Summit held in Washington, DC.

Personal Effects. There are occasions when personal effects get into foods. The means of access could be accidental or intentional. The key to control is adherence to GMPs. For example, to minimize the potential that items such as pens, pencils and thermometers fall into foods, they should not be allowed on the process floor unless they are needed. Workers who use these items should store them in scabbards or internal pockets. Never store such things in breast pockets. In fact, many operators provide their staff with garments that have no pockets to prevent such an occurrence.

Another personal effect that has created problems in the past is the bandage. If worn, a bandage should be covered. To minimize problems, there are places that mandate that any bandage worn by workers in food preparation or handling areas be brightly colored. Blue is an excellent color because there are very few blue-colored foods.

Strategic Assessment

As part of the hazard analysis, all food processors need to examine their products and processes to determine whether any biological, chemical or physical hazards exist. Physical hazards may the least common, but cannot be ignored. Whether a food safety hazard or simply a food contaminant, food companies don't want materials in the product that don't belong there. Evaluation of the potential for contamination of the product with foreign materials and whether those materials pose a realistic hazard should involve the following steps:

• A plant audit aimed at evaluating systems for pest control, foreign object removal, plant condition, shipping and receiving practices, and plant maintenance procedures.

• A review of packaging materials and container/package handling procedures, particularly when glass is the packaging material.

• A review of agricultural practices.

• A review of personnel practices, including those of maintenance staff.

• Package evaluation to ensure that product packaging is tamper-proof or tamper-evident.

• A review of consumer complaints to see whether foreign materials have been implicated in illness or injury.

Using these steps to assess physical hazards when developing and implementing a HACCP program should be more than adequate. As noted, the best means for assuring that physical hazards are properly controlled is through the use of a well-designed preventive maintenance program. It is one of the basic HACCP prerequisites.

Richard F. Stier is a consulting food scientist based in Sonoma, CA. Formerly the Director, Technical Services for The Competitiveness Initiative-Mongolia and consultant with the Agricultural Led Export Business project based in Cairo, Egypt, Stier has international experience in food safety, food plant sanitation, quality systems, process optimization, GMP compliance and food microbiology. Prior to joining these projects, he worked as an independent consulting food scientist, which allowed him to work with clients in Europe, Asia, Africa, Mexico and the U.S., as Director of Quality Assurance for Dole Packaged Foods North American operations, and with the National Food Processor's Association, where he served manager of the Microbiology Section for The National Food Laboratory. He is an active member of the Institute of Food Technologists (IFT), American Oil Chemists' Society (AOCS), the International Association of Food Protection (IAFP), and the Editorial Advisory Board of Food Safety Magazine. Stier can be reached at rickstier4@aol.com.

>