BIZTRACKS

Hygiena Dairy and Beverage Kits First to be AOAC-Certified for Entire Product Testing Workflow

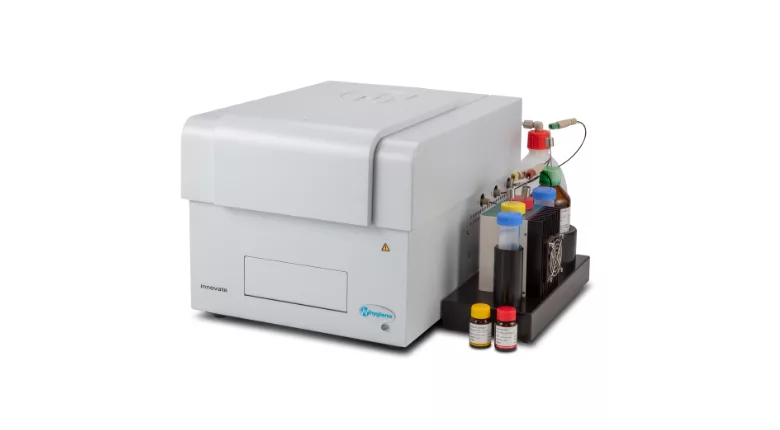

Image provided by Hygiena

Hygiena® has announced that its Innovate™ RapiScreen™ Dairy and Beverage Kits are the first methods to be awarded the AOAC RI Performance-Tested MethodsSM (PTM) Certification for the entire product testing workflow.

Hygiena’s RapiScreen Beverage Kit is a high-performance, ultra-rapid microbial screening solution specifically designed for low pH beverages, including fruit juices, teas, energy drinks, UHT-pasteurized products, smoothie mixes, and condiments. The system enables quality control results in less than 30 minutes following a preliminary incubation period, reducing product hold time from 4–10 days to 1–2 days. The rapid turnaround allows for faster release of products to the market, improved inventory turnover, and enhanced revenues.

The Innovate System, underpinning the RapiScreen Kit, detects microbial contamination far more quickly than conventional culture methods, allowing the analysis of up to 96 samples simultaneously. The simplified three-step process, coupled with RapiScreen ATP bioluminescence technology, has become the industry gold standard for screening low pH beverages and high temperature liquid fill products, eliminating lengthy plate incubation periods and shortening production times.

Hygiena's RapiScreen Dairy Kit enables swift testing on diverse product matrices, ranging from UHT milks and creams to sauces, soups and broths, and juices and beverages, yielding results in less than 30 minutes. The Innovate System’s ability to detect low levels of contamination at 24 hours offers significant cost savings, a reduction in safety stock and warehouse space costs, brand protection, and prevention of recall costs.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →