Home » Keywords: » quality control

Items Tagged with 'quality control'

ARTICLES

BIZTRACKS

Researchers Develop Active Packaging That Senses, Preserves Food Quality

November 26, 2025

EVENTS

Webinar

9/17/25 to 9/17/26

Contact: Vania Halabou

Bite-Sized Compliance Strategies: How Mars Scaled Global Quality

IMAGE GALLERIES

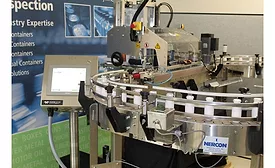

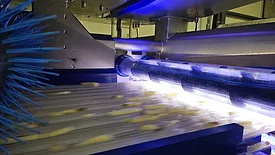

Slideshow: QA/QC and food safety technology for process improvement

Quality assurance and quality control are of the utmost importance for food manufacturers and processors. Read more in our article "QA/QC and food safety technology for process improvement."

Posted: October 30, 2020

Never miss the latest news and trends driving the food safety industry

Newsletters | Website | eMagazine

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.webp?height=168&t=1750181838&width=275)