Food Safety Versus the Green Transition

New microbial and chemical risks come with the greater incorporation of plant-based raw materials into human diets and the introduction of reusable packaging

One of the main messages in the green transition is that all of us, especially in the western, industrialized part of the world, need to modify our diets and eat less meat. From a carbon footprint perspective, this is a valid goal; however, it is important to remember that increasing the consumption of plant-based material can have detrimental effects that both food producers and consumers should consider carefully.

Microbial risks introduced with plant-based raw materials are generally limited to concerns regarding spores, molds, and the availability of additional, easily digestible sugars on which certain bacteria can thrive. These added microbial risks usually can be mitigated by adjusting recipes or process parameters—an exercise well known to the food industry, although some of the predictive tools may need to be adapted. The hazard considerations regarding the chemical safety of a diet richer in plant-based materials is more complex and may be less familiar to both consumers and producers. Finally, introducing reusable packaging may come with its own set of issues.

Using Unusual Ingredients

Major challenges in the use of plant-based material in food include removing off-flavors and anti-nutrients (which can affect the gastrointestinal tract), as well as improving the digestibility of the fibers and nutrients. Overcoming these challenges may result in long ingredient lists for the plant-based alternatives compared to traditional products. Furthermore, the use of all plant parts in sustainable food production and valorization of byproducts in different food applications might increase the exposure to chemical additives.

Plant metabolites such as natural toxins or anti-nutrients, originally generated as a defense mechanism to deter pests or herbivores,1 if ingested, may exhibit adverse health effects like allergic reactions, diarrhea, or even death. Mycotoxins, produced by fungi, can contaminate a variety of crops at the pre-and post-harvest stages and cannot be eliminated by food processing procedures.

Additional use of vegetable oils for fat enrichment of plant foods requires specific attention to the presence of mineral hydrocarbons (MOH), polycyclic aromatic hydrocarbons (PAHs), and glycidyl and chlorpropanol esters formed during refining of oils—all potential carcinogenic substances. Glycidyl fatty acid esters (GEs), which are readily hydrolyzed into the potential carcinogen glycidol in the gastrointestinal tract, form mainly during the deodorization step from heating of (di-/mono-) acyl glycerols.2

Accumulation and Increased Exposure to Heavy Metals and Pesticides

Consumption of additional plant material (including more whole grains and seeds) leads to an increased exposure to toxic metals such as cadmium (Cd) from cereals, nuts, oilseeds, and pulses, as reported for vegetarians in general.3,4

An increased consumption of non-processed, plant-based food might lead to a higher exposure to pesticide residues, but even side streams from plant-based products may accumulate pesticides from the raw materials. For example, studies at the National Food Institute of pesticide residues in byproducts from beer brewing have shown that mapping the fate of chemicals in the byproducts is relevant before reuse (e.g., of spent grains). It has been shown that spent grains contain a major part of incurred, non-polar pesticide residues in adjuncts for beer brewing.5 Thus, a need for new and more realistic exposure evaluations to determine maximum residue limits is expected in the future.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Allergens

The introduction of new and advanced food products has contributed to the general increase in the prevalence of food allergies. Many meat and dairy replacers are based on soybean, and increasing the amount of soy in the diet will increase the exposure to the known allergen.

Also, proteins from chickpea, mung bean, and rapeseed have been closely related to allergenic proteins and primary sensitization due to cross-reactions to known allergens (e.g., mustard). The processing of new plant protein sources might result in protein denaturation, aggregation, or glycation, which may reduce or aggregate the allergenic effect of certain allergens.

Hazards Due to Processing

Processing of plant products can result in the emergence of processing contaminants due to heating, drying, fermentation, or other processes, which can introduce potential chemical food safety hazards. The formation of contaminants depends on the raw material, processing technique, the temperature-time combination, and other treatment of products and protein sources. In contrast to the acute effects of microbiological spoilage, these compounds may cause chronic, long-term, adverse health effects such as carcinogenicity, even at low-level dietary exposure.

Drying, or more precisely the removal of water from the raw material or final product, will result in up-concentration of chemicals, especially heat-stable metals, stemming from the raw materials. Also, deposition of carcinogenic PAHs from the heated air used for drying should be included in the chemical safety evaluation of dried products.

Heating of food containing amino acids and carbohydrates results in non-enzymatic browning and flavor formation during Maillard reactions. However, heating in the presence of asparagine and excess reducing sugars can result in the formation of carcinogenic acrylamide. In addition, the suspected carcinogenic furans and alkylated furans may form under thermal or oxidative conditions and even from several different precursors.6 Advanced glycation end products might also be formed during the processing of plants. For these reasons, case-by-case studies are needed to exclude the formation of hazardous byproducts during heating.

Finally, fermentation can result in the formation of unwanted chemical compounds, e.g., ethyl carbamate (urethane) from ethanol and carbamyl phosphate.

Nutritional recommendations from authorities usually refer to the consumption of raw or minimally processed plant-based products (i.e., vegetables, legumes, cereals, etc.). As the green transition progresses, an increasing variety of more convenience-oriented, pre-processed food products is emerging. Consumers might perceive these food products as healthy, not being aware that the processing of alternative proteins, for example, might have destroyed many of the beneficial compounds in the matrix. Also, the actual content of vegetables in these products is often much lower than what may be expected.

Potential hazards arising from the processing of plant material and unused waste streams will need more attention in the future to prevent accumulation of chemical contaminants present in the raw materials, but also to ensure that the emergence of new contaminants due to processing is avoided. Monitoring and new screening methods for unknown hazards are needed to identify both traditional and unwanted compounds from these new food products.

In conclusion, the increased consumption of plant-based foods, the utilization of new and unused plant parts, and more sustainable production using side streams require not only microbial but also thorough chemical food safety evaluations in the future.

Hybrid Meat Products

Although recommendations from authorities and the urgency of addressing climate change require a reduction of meat consumption, it is a challenging transition to make for both food producers and consumers. Many of the functional capabilities that animal-based products naturally possess are difficult to obtain with plant-based ingredients. The result is either very long ingredient lists with many additives or a product that has a disagreeable texture, smell, and/or taste. Furthermore, most consumers are creatures of habit and find it difficult to switch diets in a short time span. To accommodate these difficulties, it may be beneficial to start by developing hybrid products—e.g., products that combine meat and plant-based ingredients. These will allow for a significant reduction in meat consumption while retaining some of the functional characteristics. But how will combining these ingredients affect the shelf life and food safety of the finished product? Can existing predictive models document shelf life and food safety of hybrid meat products?

Shelf life is an important competitive parameter for fresh and processed meat products. Shelf life testing and testing for growth of pathogenic bacteria are expensive and time-consuming, but extremely important to be able to document. Predictive models (i.e., mathematical models that predict, for example, if or how fast bacteria grow in response to a product's intrinsic and extrinsic parameters such as pH, concentrations of preservatives, or storage conditions) can be used as an alternative to costly testing. For this reason, predictive models are essential for the work and documentation of the quality departments in all parts of the food industry.

Production of hybrid meat products—where a portion of the meat has been replaced by plant-based ingredients such as vegetables, plant proteins, mushrooms, or seeds—is part of the green transition and constitutes a growing market for the meat industry. Nevertheless, the addition of ingredients of plant origin to meat products is not a new phenomenon. Many functional ingredients, including fillers and binders in emulsified products, may have plant origin. However, when a significant portion (e.g., 30 percent) of the meat ingredients are replaced with plant-based ingredients, the suitability of the available predictive models for documenting shelf life and food safety of meat products could be challenged.

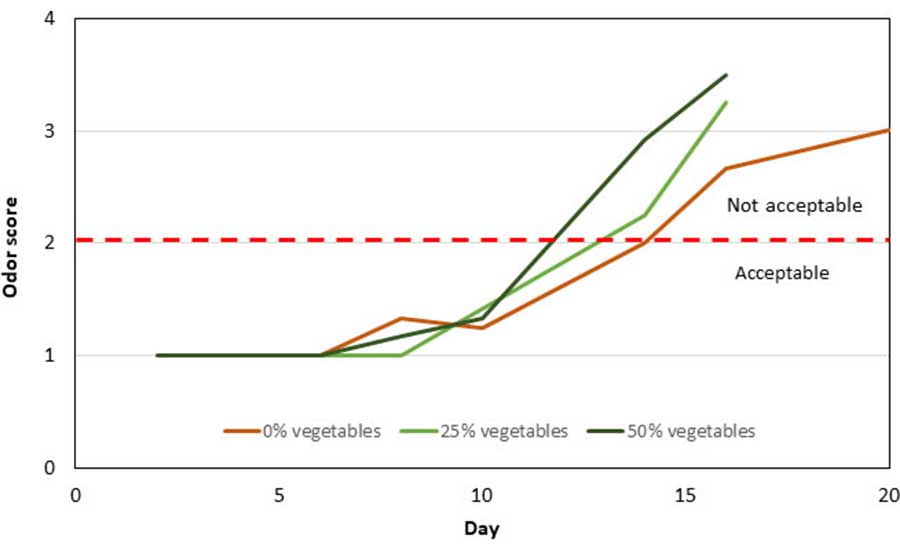

Recent research at the Danish Technological Institute has shown that hybrid meat products have a shorter shelf life than traditional, "pure" meat products (Figure 1). The hypotheses are multiple: addition of plant proteins often results in products that have a higher pH, which favors microbial growth; a higher pH also reduces the preservative effects of organic acids and other elements; and plant ingredients increase carbohydrate levels and may boost nutrition for typical spoilers in modified atmosphere (MA) and vacuum-packaged food.

Some of these factors are accounted for in the predictive models. For example, product pH is a parameter that should be measured and entered in many predictive models; however, it is not uncommon that the pH range of predictive models developed for meat products is not broad enough to cover products with added plant proteins, thereby making the models inadequate for this category of hybrid meat product.

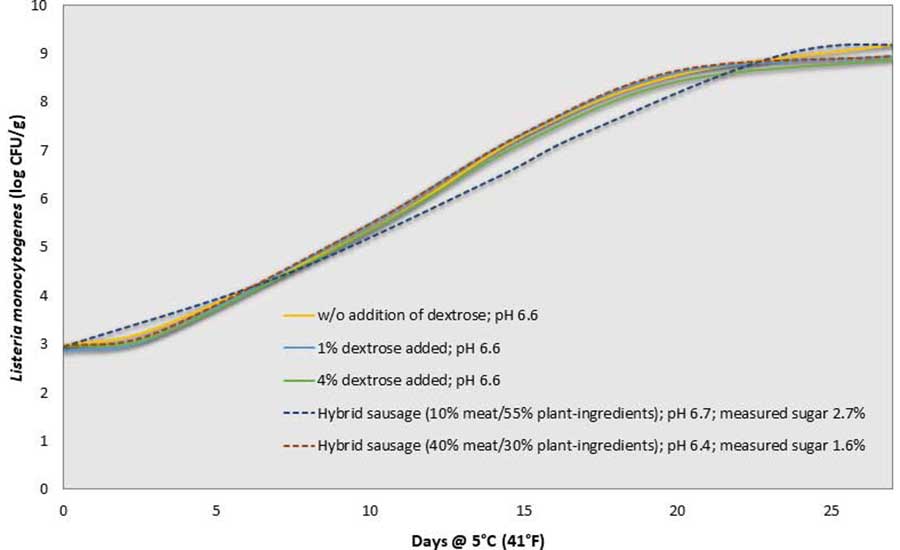

Other factors, such as the increased levels of carbohydrates after the addition of vegetables, are not accounted for at present in the predictive models developed for meat products. Preliminary challenge studies of meat and hybrid meat products with varying levels of reducing sugars (dextrose) and inoculated with Listeria monocytogenes indicate that growth of this pathogen is not affected by increased carbohydrate levels (Figure 2), as opposed to spoilage (lactic acid) bacteria, which thrive when additional carbohydrates are available. On the other hand, there may be a risk that predictive models developed for meat will underestimate the growth of Listeria monocytogenes, as replacing a meat ingredient with a plant-based ingredient lowers the level of lactic acid naturally present in meat, thereby reducing an inherent preserving factor.

From the scientific literature, it becomes obvious that there is a knowledge gap concerning growth of pathogenic and spoilage bacteria in hybrid meat products, and how well existing predictive models developed for meat can be used to predict shelf life and food safety of hybrid meat products. Predictive modeling has become an important tool in modern food production facilities and will likely have a crucial role for producers of hybrid products, as well. Therefore, thorough and extensive validations are urgently needed to determine whether existing models can be used as is, if they need to be expanded, or if completely separate models for hybrid products should be developed. Not until this work is carried out will food producers be able to confidently use predictive models to document the shelf life and food safety of their hybrid meat products.

Reusable Packaging

The reuse of materials such as plastics for food packaging is another valid idea, from a carbon footprint perspective. But reuse of packaging material for food comes with microbial and chemical hazards. Chemical hazards include concerns regarding the risk for leakage of compounds (e.g., phthalates, acrylates, oligomers, photo initiators, and other functional additives) from the packaging material to the food. Considerable knowledge gaps still exist; for example, the effect of oligomers and their contact with foods is not known. Thus, these compounds should be given special attention when developing reusable packaging. On the microbial side, mold growth is the main concern; an example involving reusable coffee cups is discussed below.

Mold growth in reusable takeaway coffee cups is a challenge for the successful implementation of a reusable takeaway coffee cup system. Minimizing the amount of single-use takeaway packaging is an important part of the green transition, and implementing takeaway packaging that can be used multiple times is of keen interest for the quick service and convenience food industry. Multiple use requires an effective and practical collection system that can ensure that the packaging can be stored hygienically during the lag time from collection until it can be washed. During this period, it is very important to minimize the risk of mold growth for food safety reasons.

Under the Environmental Technology Development and Demonstration Program (MUDP) offered by the Danish Ministry of Environment and Food, a consortium consisting of the Danish Technological Institute, a Danish reusable packaging provider, a Danish portable washing system provider, and a Danish analytical method provider has been working to develop a mold pacification method for reusable takeaway packaging.

Mold Pacification Study

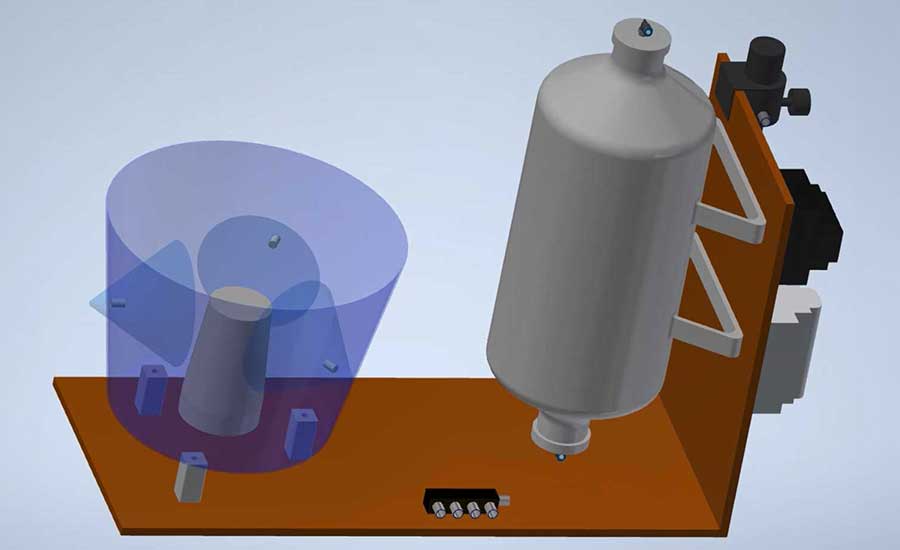

The study aimed to demonstrate the mold inhibitory effects of a food-grade mold inhibiting solution when applied in a specially designed return receptacle followed by storage in representative environments prior to being washed. The study generated valuable data for determining the effectiveness of the mold inhibiting solution, for determining the difference between storage temperatures and conditions, and to demonstrate the functionality of a newly developed prototype for the mold pacifying unit (Figure 3) to be incorporated in the return receptacles for reusable coffee cups. The unit is designed to evenly spray the food-grade mold inhibiting solution on the coffee cup.

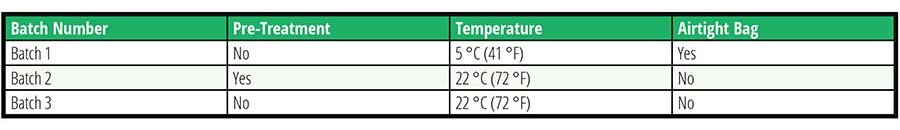

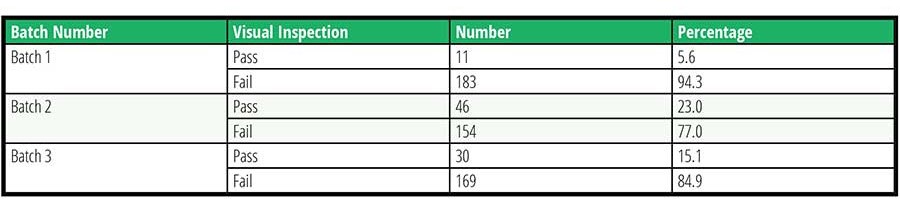

Approximately 600 coffee cups were collected after being used at an outdoor music festival in June 2023. The cups were divided into three batches, and handled and stored under three different combinations of conditions for six weeks (Table 1) before they were washed at the washing facility.

After being washed, the cups were inspected visually to indicate whether they would be suitable for reuse or if they would need to be discarded. The level of cleanliness after washing was evaluated by visual inspection, as shown in Table 2. A "pass" rating indicated no mold (can be reused), while a "fail" rating indicated the presence of visible mold (must be discarded).

The study found that storing cups in an airtight plastic bag at 5 °C/41 °F (Batch 1) was the least effective handling method, with only 5.6 percent of the cups passing the visual inspection (Figure 4).

Storing the cups at ambient temperature in a non-sealed bag (Batches 2 and 3) was a better option, and pre-treating with the mold inhibiting solution gave a slightly better result (23 percent pass) than not treating at all (15.1 percent pass).

Takeaway

Although the study did not generate as convincing results as expected, it certainly provided a basis for further investigation of the effects and conditions surrounding mold pacification. On one hand, the fact that only 23 percent of the cups were mold-free after being sprayed with the mold inhibitory solution was disappointing (Figure 5).

The active ingredient in the solution is a well-known mold inhibitor and is used widely for this purpose in the food industry. It was expected that a significantly larger number of cups would be clean after being pre-treated with the solution, compared to the non-treated cups. A contributing factor may have been the design and surface conditions of the cups.

On the other hand, the study showed that the concept of the mold pacification unit worked well, and that the spray distribution on the cup was satisfactory. Hence, the test and demonstration of the mold pacification prototype itself was a success.

Recommendations

Based on the mold pacification study, the following recommendations were made:

- The mold pacification unit can be used to distribute a food-grade inhibitory solution on a cup, but either the concentration of the mold inhibitory solution should be increased or a different food-grade mold inhibitor should be considered

- The plastic surface and design of the cup appeared to have an effect; therefore, a more suitable cup, based on hygienic design principles, should be developed.

Acknowledgments

Projects referenced in this article were conducted with financial support from the Danish Pig Levy Fund and the Environmental Technology Development and Demonstration Program (GUDP Denmark).

References

- Banach, J.L., J. P. van der Berg, G. Kleter, H. van Bokhorst, S. van-de Veen, S. Bastiaan-Net, L. Pouvreau, and E.D. van Asselt. "Alternative Proteins for Meat and Dairy Replacers: Food Safety and Future Trends." Critical Reviews in Food Science and Nutrition (June 27, 2022). https://www.tandfonline.com/doi/full/10.1080/10408398.2022.2089625.

- Cheng, W.-W., G.-Q. Liu, L.-Q. Wang, and Z.-S. Liu. "Glycidyl Fatty Acid Esters in Refined Edible Oils: A Review on Formation, Occurrence, Analysis, and Elimination Methods." Comprehensive Reviews in Food Science and Food Safety 16, no. 2 (2017): 263–281. https://pubmed.ncbi.nlm.nih.gov/33371535/.

- Ertl, K. and W. Grossler. "Grains, Whole Flour, White Flour, and Some Final Goods: An Elemental Comparison." European Food Research and Technology 244 (2018): 2065–2075.

- Alegria-Toran, A., R. Barbera-Saez, and A. Cilla-Tatay. "Chapter 3: Bioavailability of Minerals in Foods." Handbook of Mineral Elements in Food. John Wiley and Sons, 2015.

- Hakme, E., I.K. Nielsen, J.F. Madsen, L.M. Storkehave, M.S.E. Pedersen, B.L. Schulz, M.E. Poulsen, T.J. Hobley, and L. Duedahl-Olesen. "Fate of Pesticide Residues in Beer and Its By-Products." Submitted to Food Additives and Contaminants.

- Kettlitz, B., G. Scholz, V. Theurillat, et al. "Furan and Methylfurans in Foods: An Update on Occurrence, Mitigation, and Risk Assessment." Comprehensive Reviews in Food Science and Food Safety 18, no. 3 (May 2019): 783–752. https://pubmed.ncbi.nlm.nih.gov/33336919/.

- WHO European Office for the Prevention and Control of Noncommunicable Disease. "Plant-Based Diets and Their Impact on Health, Sustainability, and the Environment: A Review of Evidence." 2021. WHO/EURO: 2021-4007-43766-61591.

Lene Duedahl-Olesen, Ph.D., is Associate Professor at the National Food Institute at the Technical University of Denmark.

Nanna Bygvraa Svenningsen, Ph.D., is a Senior Consultant at the Danish Meat Research Institute, part of the Danish Technological Institute.

Rikke Hjort Hansen, M.Sc., is a Senior Project Manager at the Danish Meat Research Institute, part of the Danish Technological Institute.

Gry Carl Terrell, M.Sc., is the Business Manager at the Danish Meat Research Institute, part of the Danish Technological Institute.