Keeping It Clean—Can Sanitizing Be More Sustainable?

When implementing water-saving initiatives or using more environmentally friendly chemicals, care must be taken to avoid compromising hygiene

A variety of actions, spanning from simply changing a nozzle to implementing artificial intelligence (AI)-based technology, can contribute to making sanitizing procedures more sustainable. In this article, the authors dive into some of these actions and technologies and look at effectiveness, implementation challenges, and consequences for the final product. The research discussed is anchored in the meat industry, but in essence the results and principles are universally applicable for the entire food industry.

Walking the Line between Sustainability and Hygiene

Proper sanitation is necessary if food manufacturers want to maintain market share and manufacture products with a high level of food safety and a long shelf life. Poor hygiene can result in complaints from customers, damaged reputation, loss of new orders, or—in the worst case—food poisoning, causing illness and expensive recalls.

Many food manufacturers also look at how they can optimize their production with regard to sustainability. This includes reducing both food waste and consumption of energy and water, but also either minimizing the use of chemicals for cleaning and sanitizing (C&S) or, alternatively, switching to more environmentally friendly chemicals. As C&S is one of the most water-consuming processes in the food industry, it is reasonable to investigate whether the amount of water used during C&S can be reduced. However, care must be taken not to compromise food safety and shelf life, which are important competitive parameters for all food manufacturers.

Cleaning is Important to Obtain Good Shelf Life

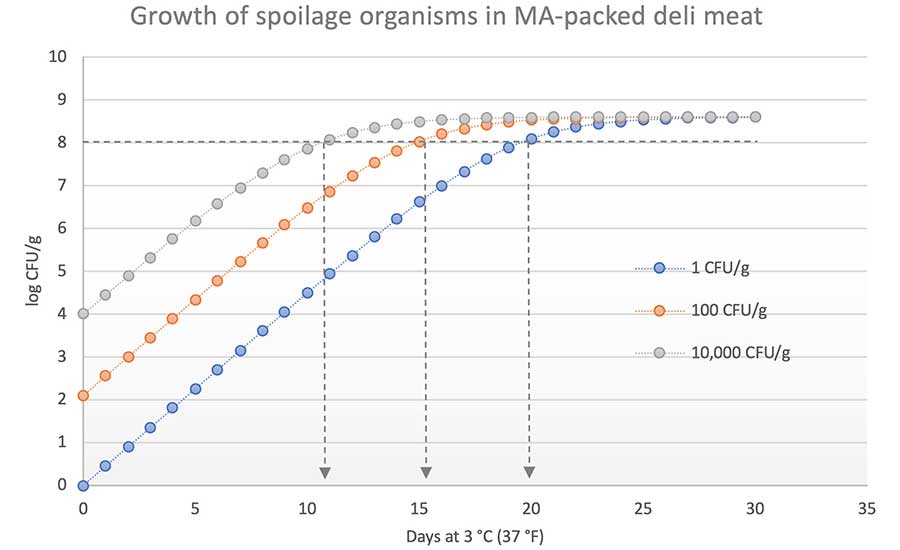

Both food safety and shelf life rely on high standards of hygiene. In fact, the shelf life of a product may be extended by weeks if starting out with a bacterial count of < 1 CFU/g rather than 1,000 CFU/g. This can be illustrated by looking at the growth of the spoilage organisms Leuconostoc carnosum and Leuconostoc mesenteroides in modified atmosphere (MA)-packaged deli meat. These two organisms are the main culprits causing blown packages (Figure 1), as they produce visible amounts of gas if they are allowed to grow to high levels (i.e., around 8 log CFU/g).

A newly developed predictive model in DMRIPredict1 shows that the time to reach 8 log CFU/g in a lightly preserved deli meat product stored at 3 °C (37 °F) is 20 days if the starting point is 1 CFU/g. If starting out at 100 CFU/g, then the time to reach 8 log is reduced to 15 days. If the initial count increases to 10,000 CFU/g, then the time to reach 8 log is only 11 days (Figure 2).

This direct connection between initial bacterial count and shelf life is also observed when looking at total viable counts (TVC). A shelf life study of heat-treated sausages sampled from the same production line showed that the shelf life was approximately one month when the initial TVC was at the < 10–100 CFU/g level (four out of ten packages with < 10 CFU/g). Intensified cleaning in the production area reduced the initial count to < 10 CFU/g in nine out of ten packages, which extended the shelf life to more than two months—i.e., more than a doubling of the shelf life (results not shown).

Thus, keeping the effect on product shelf life in mind, when implementing water-saving initiatives or switching to using more environmentally friendly chemicals, care must be taken to avoid compromising hygiene in the production environment. Shorter product shelf life leads to greater food waste, which has a profound effect on the overall sustainability of food production.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Sustainable Cleaning with Less Water

Cleaning in the food industry usually involves using substantial amounts of water, energy, and chemicals, which is problematic from both an economic and sustainability viewpoint. Industry is looking for ways to address this without compromising business operation or product quality and safety.

Over the course of two years, the Danish Technological Institute (DTI) and the Scandinavian meat industry have explored various methods to reduce the significant water consumption associated with cleaning at slaughterhouses. Two important criteria for the methods were established:

- The time used on cleaning cannot be increased

- The resulting quality of cleaning cannot be affected.

Choosing the Right Nozzle can Save Water

Generally, a cleaning process is divided into five subroutines:

- Pre-rinse (soil removal)

- Application of detergent

- Rinse

- Sanitizing (microbial inactivation)

- Final rinse.

The largest water consumption is usually associated with the initial pre-rinse for two reasons: it is the most time-consuming step in the cleaning program, and water nozzles with a high flowrate (40–50 L/min) are often used. At pig slaughterhouses, it has been estimated that about 30–50 percent of the water used for cleaning goes to hose down floors and equipment at the pre-rinse step.

The potential water savings from switching from a high-flowrate nozzle to a water-saving nozzle (30 L/min) was tested at a large pig slaughterhouse in Denmark. The water-saving nozzle was tested for two weeks by the cleaning crew in the cutting and deboning areas. The nozzle was used for all three rinse steps.

The test results showed that water usage, on average, was reduced by 10 percent compared to the normal consumption. Daily variations were seen in water savings and between the different cleaning stations depending on the task/equipment and the crew member performing the cleaning. The use of the water-saving nozzle did not prolong the time used for cleaning in the area, and based on the daily standard inspections, the final cleaning quality was not affected.

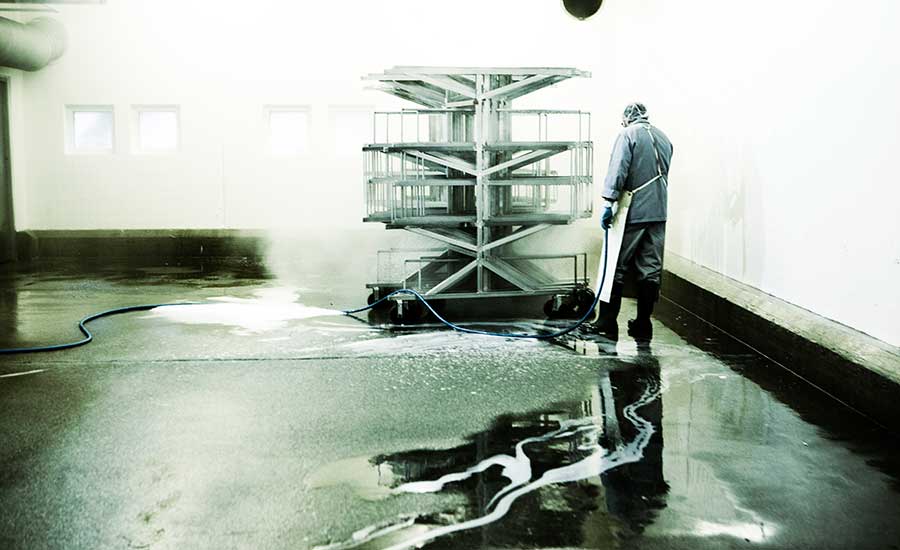

One of the challenges associated with the use of the water-saving nozzle was that the cleaning crew found it difficult to hose larger meat residues off the floor. However, this challenge can be turned into an asset, since it could motivate and nudge the cleaning crew to use squeegees to remove larger meat pieces from the floor, rather than using the water hose as a "broom" (Figure 3).

A 10 percent reduction in water consumption can have a significant impact not only on the water usage, but also on the energy usage, as the pre-rinsing is performed with warm water (45–55 °C/110–130 °F). Combined with minor adjustments of the standard operating procedures for the cleaning crew, a simple action such as switching out the nozzle on a hose can have a significant financial and environmental impact and can help the food industry move toward more sustainable production.

Can C&S be Combined into a One-Step Process?

Revisiting the five steps of cleaning, another way of optimizing could be to combine the C&S steps into one operation, potentially leading to time, water, and chemical savings. Detergents that combine C&S are already on the market, but how effective are they in reality? The combined C&S products are often based on an alkaline foam detergent containing chlorine. Chlorine efficiently removes difficult soils, such as proteins, and can be a highly effective disinfectant with a broad-spectrum activity against a wide variety of microorganisms. However, the effectiveness of chlorine as a disinfectant is greatly impacted by the presence of soil. The less soil on the surface, the more effective chlorine is at inactivating microorganisms.

To be approved for use in the food industry, the disinfectant must pass an efficacy test. This test is carried out as a suspension test in a laboratory, where the bactericidal effect against a wide range of microorganisms is documented. For example, for a product to pass the European standard for disinfectants used in the food industry (EN 1276), it must achieve a 5-log reduction of selected microorganisms. It can, however, be difficult to translate laboratory-generated results into the effect obtained in actual food production. Many factors will interfere with the final result, including the presence of soil residues on the surfaces, surface type, human factors, etc. Validating the efficacy of a given product under conditions mimicking an industrial setting is highly recommended.

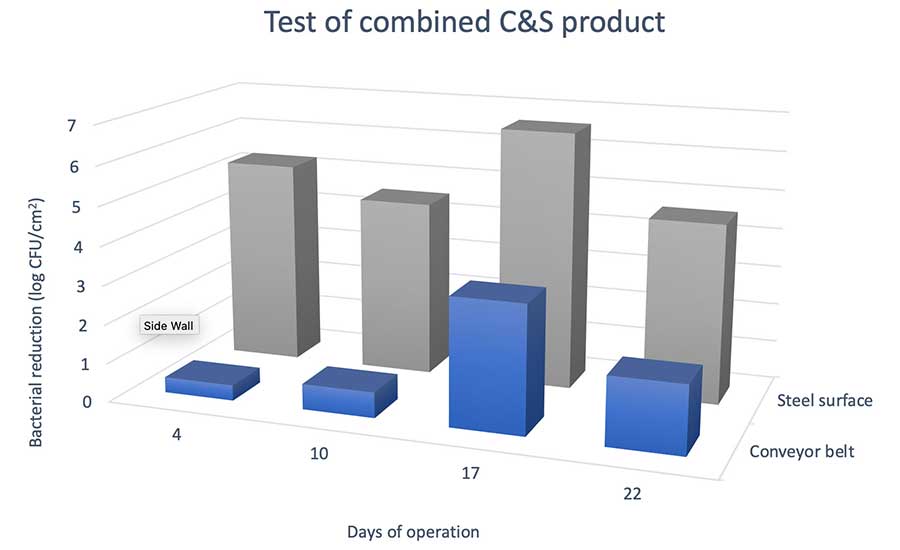

DTI has tested the effect of a combined C&S product in a pilot-scale trial, simulating the conditions found in a low-soil section (e.g., the packaging area) of a meat processing plant. The trial was conducted using the same cleaning equipment and settings as are used industry, including water pressure (25 bar/360 psi), water temperatures, and types of nozzles and soils. The combined C&S product was tested on a modular conveyor belt and a steel surface, as these are the types of surfaces most frequently found in the packaging area of a meat processing plant (Figure 4).

To measure the long-term effect of a C&S product, the following routine was performed every workday for 3.5 weeks:

- The surfaces were soiled with pork belly meat inoculated with a cocktail of spoilage bacteria. The meat was placed on the test surface and left for approximately 18 hours to simulate a standard production day.

- After 18 hours, the pork belly meat was removed, leaving a thin layer of meat juice, small pieces of meat, and the inoculated bacteria on the surface.

- The surface was pre-rinsed with lukewarm (45–50 °C/110–120 °F) water, after which the combined C&S product was applied. The combined C&S product was applied according to the manufacturer's instructions (3 percent solution, 20 minutes contact time) before it was rinsed off with room-temperature (20–25 °C/68–77 °F) water.

The effect was evaluated by visual inspection and by taking swab samples of the surface for microbial analysis. The surface was swabbed before and after the C&S procedure on selected days of the test (Figure 5).

On the steel surface, the combined C&S product was effective in both cleaning and disinfecting; the surface was visually clean, and the bacterial count was reduced by 4.5–6.5 log CFU/cm2 after the procedure. On the modular conveyor belt, however, the result was less encouraging. Although the surface was visually clean after the procedure, almost no sanitizing effect was observed on the belt during the first 10 days of the test. To investigate whether adding more detergent could increase the effect, another layer of foam detergent was added after day 10. Adding the extra detergent resulted in a slight improvement of the effect, as the bacterial count was reduced by 1.5–3 log CFU/cm2, but it was still far from the effect that would be expected and required in the food industry.

In conclusion, although switching to a combined C&S product potentially can save time, water, and chemicals, the authors advise never to rely solely on whether a product is "approved." To avoid compromising a high level of hygiene and food safety, it is important to validate the effect of the product under the specific circumstances of the intended use.

Assisted Detection and Improved Cleaning

Dealing with natural contamination on incoming raw material is a challenge in many areas of the food industry, and fecal contamination on carcasses is perhaps the most challenging of all. Over the years, DTI has done substantial research and development to address this issue. Two of the projects are detailed below.

Automatic Detection of Fecal Contamination on Beef Carcasses using AI

The detection of fecal contamination on beef carcasses is an important processing and inspection task throughout the cattle slaughter process. Fecal contamination can occur during the slaughtering process, and if not detected and properly addressed, it can lead to poor microbial meat quality, foodborne illness, and other health risks for consumers.

Various methods are used to detect fecal contamination on carcasses. One common method is visual inspection, where trained personnel visually inspect the carcasses for presence of fecal matter. However, this method is subjective, can be time-consuming, and it may be difficult to detect contamination at low levels. An automated system may overcome these obstacles.

A few commercial technologies to improve the detection of fecal contamination on beef carcasses are already on the market. One of them is a fluorescence imaging system that uses fluorescent dyes to detect the presence of fecal matter, relying on the inherent fluorescence of chlorophyl. Thus, the technology requires that the cattle has consumed chlorophyll-containing feed (e.g., fresh grass), which is rarely the case in Denmark.

Engineers and data scientists at DTI have developed a vision-based detection system. The system uses a combination of high-resolution RBG cameras and AI to detect fecal contamination on the hind legs of the carcasses. Once detected, the system pinpoints the contamination to the line worker, who in turn can remove the contamination swiftly and with great precision from the location pointed out by the system.

In the development of the detection system AI, a machine learning model was trained using a dataset of labeled, high-quality images of contaminated and uncontaminated carcasses. The model was trained to recognize a huge variation of visual patterns associated with fecal contamination by looking at several critical parameters such as color, texture, and shape of the fecal matter. After thorough training, the system can interpret new images based on the visual patterns it has learned and determine whether fecal contamination is present.

The detection system is currently used in slaughter lines at several Danish cattle abattoirs, where it automatically analyzes images of beef carcasses and identifies the presence of fecal contamination on the hind legs. Development of the system is ongoing, with the aim of enabling the system to eventually cover the full carcass surface.1

Using Steam Vacuum for Efficient Removal of Contaminants

As described above, fecal contamination can occur during the slaughter process and, once detected, it is equally important to be able to efficiently remove the contamination. The standard procedure in many abattoirs is to trim off the contaminated tissue, which in theory will physically remove all contamination. The downsides of trimming include significant loss of product and downgrading of trimmed carcasses, which affects the profitability of the abattoir and hurts the environment due to food loss.

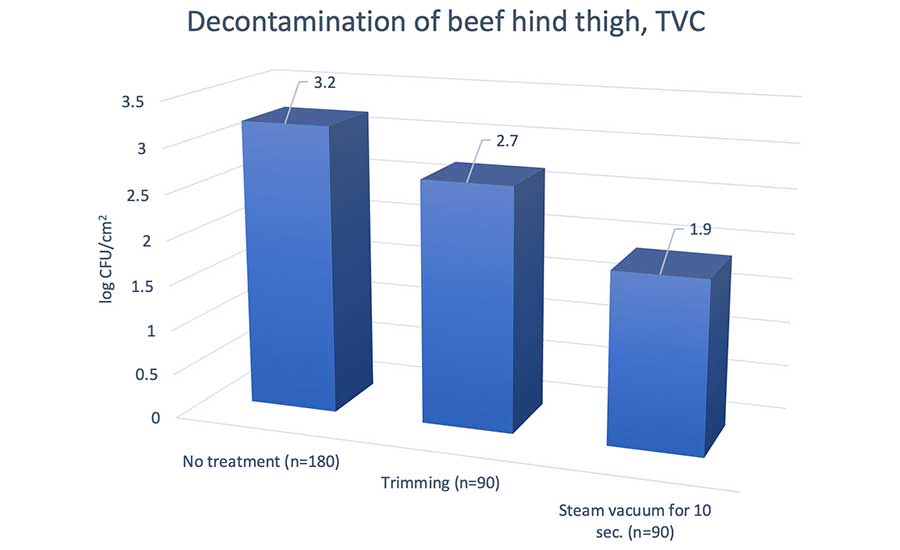

An alternative to trimming is steam vacuuming, which has proven more efficient than trimming in removing contaminations such as fecal matter. With steam vacuuming, the contamination is physically removed using suction, without needing to remove any tissue. The time used for a steam vacuuming step is equivalent to the time needed to trim. Thus, steam vacuuming improves slaughter hygiene, increases food safety, and prevents downgrading of the carcass due to trimming of contaminated areas, without sacrificing the processing speed (Figure 6).

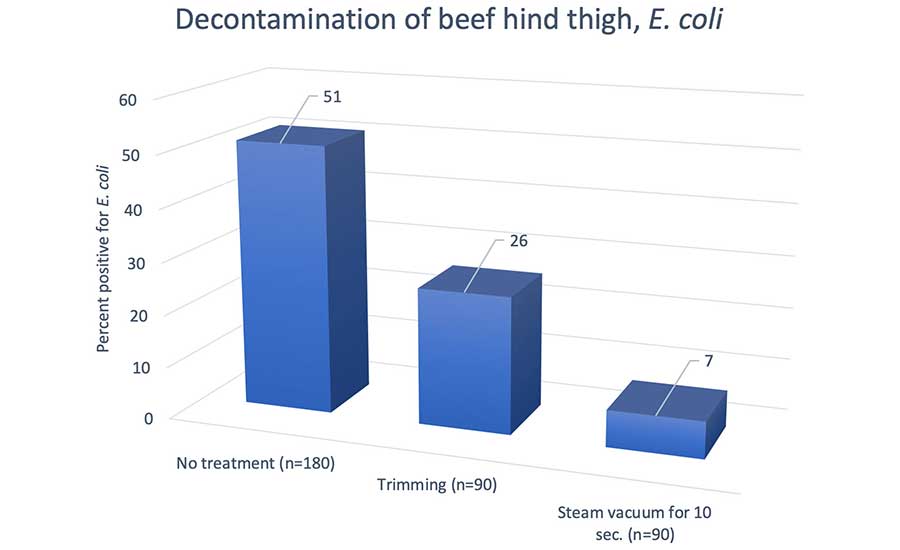

DTI has tested steam vacuuming systems on slaughter lines for pigs, cattle, and lamb, and has found a general reduction in the total viable count (TVC) of Escherichia coli on the carcasses.Experiments have shown that a ten-second steam vacuum decontamination treatment of beef carcasses, on average, reduced the TVC by 1.3 log CFU/cm2, while trimming reduced the TVC by only 0.5 log CFU/cm2 (Figure 7).

The steam vacuum decontamination treatment also reduced the number of E. coli positive samples more efficiently than trimming, with 26 percent positive samples after trimming compared to only 7 percent positive samples after a ten-second steam vacuum treatment (Figure 8).

Takeaway

As a food producer, targeting sanitizing processes in the quest to become more sustainable is not a bad idea. For most producers, options are available for cutting down on the consumption of water, energy, and chemicals. When cleaning the processing environment, a simple change of a nozzle can bring about noteworthy water savings when combined with a minor adjustment of the sanitizing procedure. Care must be taken, however, not to let these endeavors compromise hygienic standards. Inadequate hygiene and poor microbial product quality not only increases the risk of presence of pathogens, but also significantly impacts product shelf life.

The detection and removal of contamination is an important issue throughout the food industry. On carcasses, AI has been shown to be a powerful technology to aid in the detection of contamination, and steam vacuuming is an efficient and convenient way to remove contamination, once detected. By walking the line with care and being smart about the hygiene processes, it is indeed possible to make sanitizing in the food industry more sustainable.

Acknowledgments

The results reported in this article originate from projects supported by the Danish Pig Levy Fund, the Danish Cattle Levy Fund, and the Danish Ministry of Higher Education and Science.

References

- Danish Meat Research Institute. "Predictive Models for Meat." http://www.dmripredict.dk/.

- TheDMRI. "AI assists in cattle abattoirs." May 11, 2022. YouTube. https://youtu.be/42c-gMhvNN8

Emma Bildsted Petersen is Section Manager at the Danish Meat Research Institute (DMRI) of the Danish Technological Institute (DTI).

Rikke Hjort Hansen is Senior Project Manager at the DMRI of the DTI.

Anette Granly Koch is Senior Scientific Officer at the DMRI of the DTI.

Freja Lea Lüthje is Specialist at the DMRI of the DTI.

Gry Carl Terrell is Business Manager at the DMRI of the DTI.