New Approaches to Meat Safety

Application of new technologies, such as vision systems and Listeria Action Cards, will help meat processors reduce product contamination

When talking about meat safety, we often associate it with microbial safety—i.e., is it safe to eat without contracting a foodborne illness? However, meat safety as a concept can be viewed in a wider perspective, with regard to both causes (physical, chemical, and microbiological) and consequences (personal safety and corporate financial safety). The causes are discussed below, but the wider definition of the consequences may require a brief introduction.

"Personal safety" is meant to refer to the risk of becoming ill from consuming an unsafe product. This can happen if the meat contains pathogenic bacteria, pieces of metal, or hazardous chemicals, for example. What if a meat product contains small pieces of plastic? Strictly speaking, there is no direct danger in consuming tiny pieces of plastic, but in theory there is a risk that the plastic may be contaminated with microorganisms. For the company producing the meat product, small pieces of plastic can be devastating.

As a consumer finding a piece of plastic in a sausage, one can wonder what else went wrong during the production process. The consumer may lose confidence in the company's ability to produce safe meat products, may stop buying the company's products, and may even post pictures on social media of the contaminated product. Recalls, loss of business, and ultimately closure is a real risk for the company—a risk the authors have coined "corporate financial safety." In this article, the authors present novel approaches to addressing both well-known and emerging challenges posed by physical and microbiological risks in the meat industry.

Hazards Associated with Meat and Meat Products

A wide range of hazards can compromise the safety of meat and meat products, with these being categorized as physical, chemical, and biological hazards. As defined by the Codex Alimentarius Commission, a foodborne hazard is a biological, chemical, or physical agent, or a condition of food, that has the potential to cause an adverse effect on human or animal health.

Physical hazards commonly include foreign materials introduced to food products throughout the production chain, such as bone chips, metal, glass, and stones. The most common chemical hazards found in meat are allergens, pesticides, heavy metals, residues of animal drugs, mycotoxins, and chemicals from cleaners and sanitizers. Chemical hazards can cause gastrointestinal distress, damage to other organs, and an immunological response that could lead to death. Both physical and chemical hazards are the cause of a sizable proportion of food product recalls.1,2 Biological hazards include pathogenic bacteria, fungi, viruses, prions, protozoans, and parasites, and can originate from the raw product or from food processing. The major consequences of biological hazards are foodborne illness outbreaks, with the most common manifestation being gastrointestinal-related clinical signs, including distress, diarrhea, and vomiting—and in some instances, death.

Physical hazards in meat can be foreign materials from the environment that have been unintentionally introduced, such as metal, glass, insects, wood, or rubber, or naturally found materials in the raw product, such as bone chips larger than 2 mm. These hazards can cause illness and injuries to those who ingest them, as well as psychological trauma.3 Previous studies identify a considerable proportion of food safety incidents and consumer complaints to be associated with physical hazards. As an example, Park et al.4 reported that 20.4 percent of 975 recorded food safety incidents between 1998 and 2016 in South Korea were caused by physical hazards, mainly plastic, glass, and insects.

In another example, Cavalheiro et al.3 reported a total of 408 consumer complaints due to physical hazards in meat and meat products, being registered with the largest consumer complaint digital platform in Brazil, between 2016 and 2018. The products with the greatest percentage of complaints were sausages and hamburgers, with only 0.5 percent of complaints associated with fresh bovine meat. Bone chips and plastic represented the major physical hazards found. Physical hazards can be controlled through the appropriate implementation of Hazard Analysis and Critical Control Points (HACCP) to ensure that critical control points for potential physical contamination are monitored.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Despite the appropriate implementation of quality assurance programs, such as HACCP, physical hazards continue to pose a food safety risk, as failures can occur at any stage of the processing chain. Therefore, product monitoring with the help of screening methods, such as metal detectors, sensors, X-ray equipment or ultrasound measurements, should also be used to minimize the risks posed by the presence of these hazards. In addition, it is important that processing plant equipment is regularly inspected and maintained, as most physical hazards arise from problems with equipment and packaging materials.1

Among the biological hazards that can be found in meat are bacteria, viruses, mold, prions, protozoans, and parasites. Typical clinical symptoms of foodborne bacterial and viral illnesses include acute diarrhea, abdominal cramps, vomiting, or some other manifestation in the gastrointestinal tract. Bacterial pathogens cause the most severe illnesses and deaths, with viruses commonly causing less severe illness (despite being responsible for a substantial number of foodborne illnesses). In their invasive severe form, some bacterial pathogens are associated with syndromes affecting the central nervous system or various organs, as well as being involved in various chronic sequelae. Individuals with suppressed or compromised immune systems are more susceptible to severe foodborne microbial illness.

Biological hazard-associated issues become more challenging with the emergence of pathogens with increased virulence or of low infectious doses, or with resistance to antibiotics used in animal production or to antimicrobial additives used in meat processing. In general, the most important food safety challenge in meat products is the need to control pathogenic microorganisms, especially bacteria and viruses. In certain regions, parasites are a significant area of interest. Spoilage microorganisms are also of concern because they cause a loss of food quality and can pose a toxicological health risk due to the production of biogenic amines.5

The primary source of contamination of biological origin on meat is the animal's intestines and the hide. The hide carries elevated levels of microorganisms originating from animal feces, soil, and water accumulated during animal production, transportation, and holding before slaughter. In addition to feces, another important source of biological contamination in pork products is the pig snout and throat areas. Additional sources of contamination include the processing environment, equipment, utensils, and humans contributing through cross-contamination.

During carcass deboning and cutting, contamination on external carcass and equipment surfaces is spread and distributed on equipment and other environmental surfaces, as well as other carcasses or meat cuts, which leads to a cycle of contamination spreading and cross-contamination. Contamination may be spread to meat during cutting, processing, storage, merchandizing, preparation, and serving, if manufacturing and hygienic practices allow. If not properly handled, processed, preserved, and prepared for consumption, meat supports the growth of various microorganisms, leading to spoilage and foodborne illness.

Meat processed under sanitary and hygienic conditions should be contaminated infrequently and have low concentrations of pathogens compared to those of spoilage-causing bacteria. Comminuted, and in general non-intact meat products (such as those that have undergone brining) contain higher contamination levels than carcass or intact-product surfaces, due to cross-contamination from grinders and utensils, spreading of contamination, and greater surface area. Appropriate management of the slaughter and processing hygiene through implementation of preventive measures and HACCP will minimize the risk posed by these products. However, the consumption of undercooked, non-intact meat products is likely to pose a higher risk of foodborne illness than the consumption of properly cooked, non-intact, or intact meat products.

Vision Technology

Sophisticated technology can be used to minimize physical risk factors. In a world with an increasingly faster workflow, vision technology can help operators ensure that no foreign bodies get past the control. Vision technology not only uses visible light—which is a small part of the electromagnetic spectrum—but also generates a multispectral image that captures image data within specific wavelength ranges across the electromagnetic spectrum. The wavelengths may be separated by filters or use sensors that are sensitive to particular wavelengths, including light from frequencies beyond the visible light range (i.e., the infrared and ultraviolet area). Multispectral imaging measures light in a small number (typically 3 to 15) of spectral bands, including red, green, and blue.

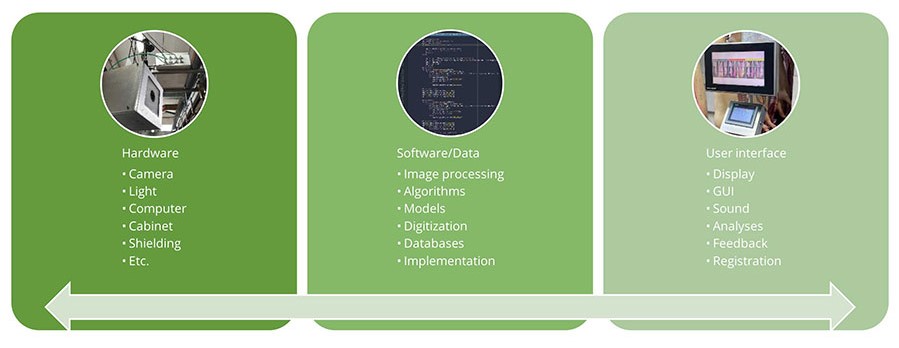

A vision system includes three important pillars (Figure 1): the hardware, the software, and the user interface. It requires highly skilled specialists to build, due to the extraordinarily complex structure. The light and camera must interact, the computer requires exceptionally high processing power and speed, the software must include both image capture and algorithms, and the user interface must be clear and precise.

Figure 1. The Vision System Includes Hardware, Software, and User Interface

Vision Systems for Postmortem Control in Slaughterhouses

Vision systems can be a valuable future tool for meat inspectors. The equipment can perform with high accuracy and precision, and can be established independently of operators and slaughterhouses. The visual-only (i.e., hands-free) inspection takes place after evisceration. Visual-only inspection (VOI) is a risk-based, postmortem meat inspection technique that does not use incision and palpation. The decision to perform VOI is determined on a herd-by-herd basis and is informed by herd health information from the producer, ante-mortem inspection results, and other information. The most important challenge in using vision systems for VOI is that the inspection must cover all visible surfaces of the carcass and cover both geometric differences (e.g., pneumonia) and spectral differences (e.g., fecal contamination). At the same time, contamination can be difficult to define, as different kinds of contamination have great variances, and small particles must be identified.

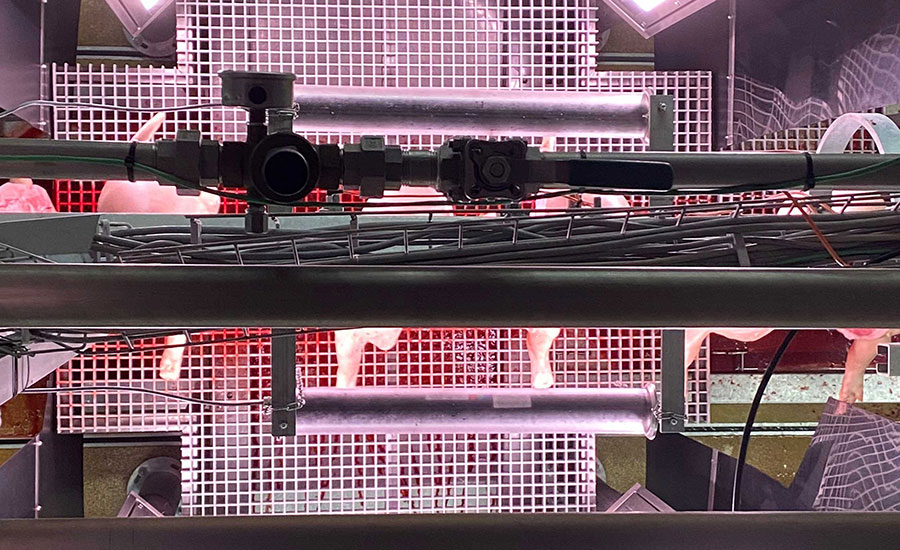

The Danish Meat Research Institute (DMRI) is developing a vision system for VOI, in close cooperation with the Danish Meat Inspection Authorities and a Danish slaughterhouse, where a test system is currently installed. The lights and cameras are mounted in cabinets (four in total) and can cover all visible surfaces of the entire pig carcass (Figure 2). The system generates a total of 48 high-resolution images (24 infrared and 24 red-green-blue color). Within a few seconds, all of this data must be stored and analyzed, the results relayed to the meat inspector, and the system reset in preparation for the next carcass.

Figure 2. Test Vision System Installed at a Commercial Slaughterhouse

The first algorithms have been developed to find fecal and bile contamination and chronic pleurisy in the cave of the carcass. During the coming months, all data from the vision system and the regular post-mortem inspection will be collected and analyzed for correlation and uniform classification. The next step is to implement the graphical interface for the operators so that they will know the locations of the contaminations.

Vision Systems for Detection of Foreign Bodies

Low-density materials like plastic and paper are used extensively in food production. However, they cannot be found by the conventional technologies for foreign body detection—i.e., X-ray and metal detectors, which target high-density materials like metals. Even small fragments of plastic or paper can cause considerable inconvenience and loss of consumer confidence, and can result in significant recall costs for the company.

With the newest developments in vision technology, it is possible to recognize diverse types of plastic. A drawback—which is a challenge for all equipment designed to find foreign bodies in meat and meat products—is that the plastic must be visible at the surface of the product. Also, the color of the plastic is particularly important for successful detection with the vision system; the more distinctive the difference is between the color of the product and the color of the contaminant, the better the chance of a reliable detection. Thus, in meat and meat products, blue plastic is easier to find compared with red, white, or transparent plastic.

By using multi-spectral cameras with special illumination, a vision solution can detect the unwanted components, give instant feedback, and allow the processor to stop the process and discard lesser amounts of product where fragments that deviate from the natural colors of the product are found.

Listeria Action Card: The Hunt for Listeria-Free Meat

Listeria monocytogenes is a bacterium that can potentially cause disease, but at the same time is widespread in our environment. Almost all animal species, including humans, can be asymptomatic carriers of the bacterium. In pigs, for example, the tonsils have been identified as the organ where Listeria most often occurs,6 creating a risk for Listeria to be introduced to the slaughter environment in connection with (or after) slaughter. Listeria is a ubiquitous environmental bacterium that thrives well in humid environments, such as abattoirs. With a complex production apparatus and access to abundant nutrition, there is a risk that Listeria can establish itself in abattoirs.

Due to a remarkably high focus on cleaning and slaughter hygiene in modern Danish abattoirs, the prevalence of Listeria is generally very low. However, in light of increased microbiological requirements for fresh meat, there is interest in further minimizing the occurrence of Listeria in abattoirs—if possible, to completely eliminate it. Listeria-free fresh meat is already being requested in the market.

Need for a Practical Tool

As Listeria is ubiquitous in the production environment at abattoirs, it can be a time-consuming and costly undertaking for a quality manager to decide how to implement Listeria reduction measures. Everyday life as a quality manager in an abattoir can be exceptionally busy amid dealing with regulatory requirements, customer audits, administrative tasks, and other functions. The need was identified to develop a concrete tool that would not only help audit and monitor, but also make specific suggestions for activities (action points) to help reduce the prevalence and level of Listeria in fresh pork. The tool needed to be specific enough to suggest direct, hands-on measures, but also broad enough to cover the large diversity in the construction of abattoirs in terms of degree of automation, slaughter methods, sequence of sub-processes, etc.

Systematics and Flexibility

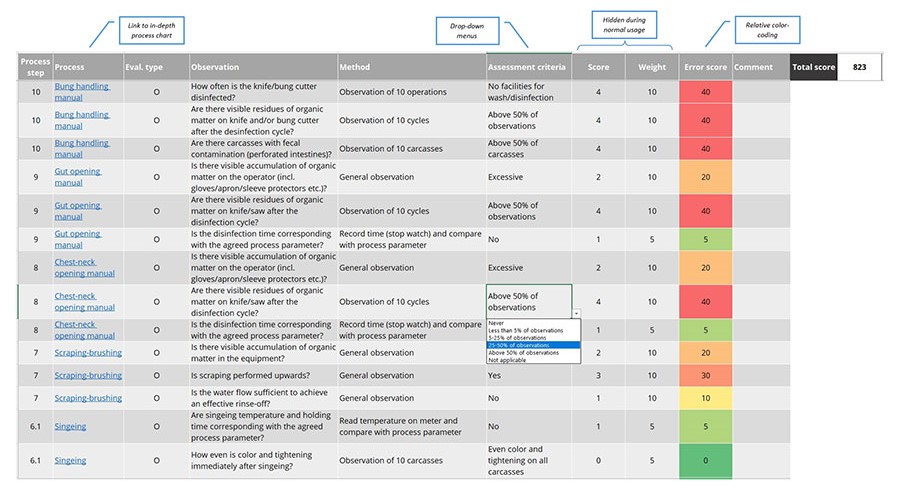

At the request of the industry, DMRI is developing a guideline to encompass the many different sub-processes that take place at abattoirs. This work resulted in an interactive tool called the Listeria Action Card (LAC) that reviews every conceivable process at a modern pig abattoir, step by step and in minute detail, and relates these steps to their influence on the occurrence of Listeria. Specifically, the LAC contains an evaluation form that can be adapted to individual abattoirs, where the quality manager, by answering a number of concrete questions, can review the company's processes and form a visual overview of which sub-processes have the greatest impact on the risk of introducing Listeria to the abattoir or causing cross-contamination (Figure 3). The discovered "high-impact" processes will be the most effective places to intervene first.

Figure 3. Example of Visual Overview of Sub-Processes Relating to Listeria Prevalence in Abattoirs

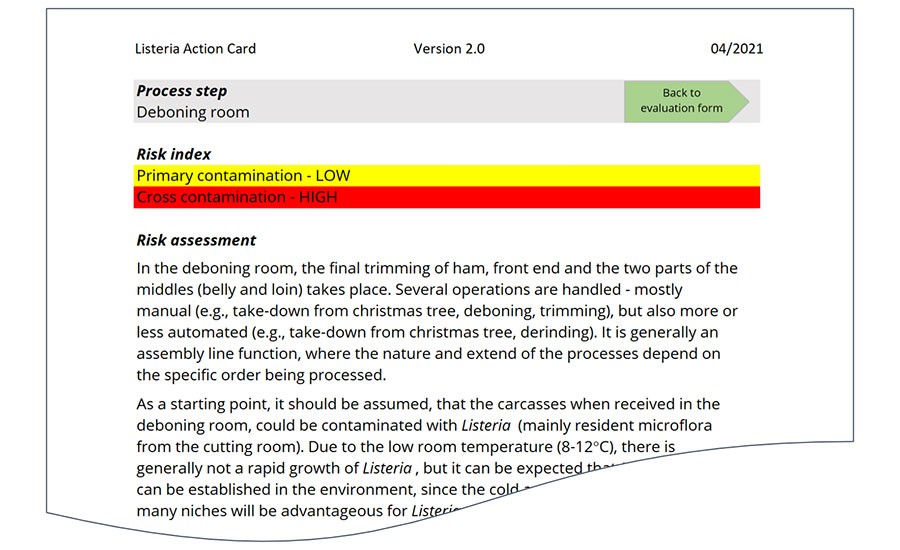

The LAC systematically reviews each sub-process from lairage to deboning—31 different processes in total. Each process includes a risk index, a risk assessment, suggestions for identifying errors, proposed short- and long-term remediation strategies, and references to relevant reports from previous DMRI projects and scientific papers (Figure 4). In addition, the LAC contains sections that, using the same systematics, review more general topics dealing with food safety culture, management, equipment, buildings, and microbiological methods.

If a company needs more in-depth knowledge or faces a requirement for documentation, it can consult the LAC literature list, which includes both reports from previous DMRI projects and scientific papers, with a brief introduction to the main results of each reference. The LAC has become a "one-stop shop" that enables companies to evaluate their performance, find concrete suggestions for improvement, and provide necessary documentation.

Figure 4. Listeria Action Card (LAC) Process Chart Example, Starting with General Risk Index and Risk Assessment

The LAC is currently being tested at selected abattoirs. It is designed so that each abattoir can adapt the LAC to its own needs. This means that some abattoirs have chosen to concentrate on certain sections for immersion in the processes where most of the low-hanging fruit is expected to be found. Others have chosen to review all of the processes from end to end, form an overview, and establish a universal baseline. In this way, the LAC gives companies the freedom to work on reducing the risk of Listeria occurrence and growth in a way that makes sense for the specific abattoir.

Note

All of the reported results originate from projects supported by the Danish Pig Levy Fund.

References

- Batt, C. A. "Chemical and Physical Hazards in Food." Reference Module in Food Science. Amsterdam, The Netherlands: Elsevier, 2016.

- Wallace, C. A., W. H. Sperber, and S. E. Mortimore. "Recognising Food Safety Hazards." Food Safety for the 21st Century: Managing HACCP and Food Safety Throughout the Global Supply Chain. Chichester, UK: John Wiley and Sons Ltd., 2018.

- Cavalhiero, C. P., M. C. A. D. Silva, J. S. F. Leite, S. K. R. D. S. Felix, A. M. Herrero, and C. Ruiz-Capillas. "Physical hazards in meat products: Consumers' complaints found on a Brazilian website." Food Control 108 (2020).

- Park, M. S., H. N. Kim, and G. J. Bank. "The analysis of food safety incidents in South Korea, 1998–2016." Food Control 81 (2017).

- Ruiz-Capillas, C. and A. M. Herrero. "Impact of Biogenic Amines on Food Quality and Safety." Foods 8 (2018).

- Oswaldi, V., J. Dzierzon, S. Thieme, R. Merle, and D. Meemken. “Slaughter pigs as carrier of Listeria monocytogenes in Germany.” Journal of Consumer Protection and Food Safety 16 (2021).

Marchen Hviid, M.Sc., is a Senior Scientist at the Danish Meat Research Institute at the Danish Technological Institute in Denmark.

Gry Carl Terrell, M.Sc., is a Senior Consultant at the Danish Meat Research Institute at the Danish Technological Institute in Denmark.

Marta Hernandez-Jover, Ph.D., is a Professor of Veterinary Epidemiology and Public Health at Charles Sturt University in New South Wales, Australia.