How a Mature Food Safety Culture Can Prevent Foreign-Body Contamination

Whole-team engagement makes for a more thorough, effective result

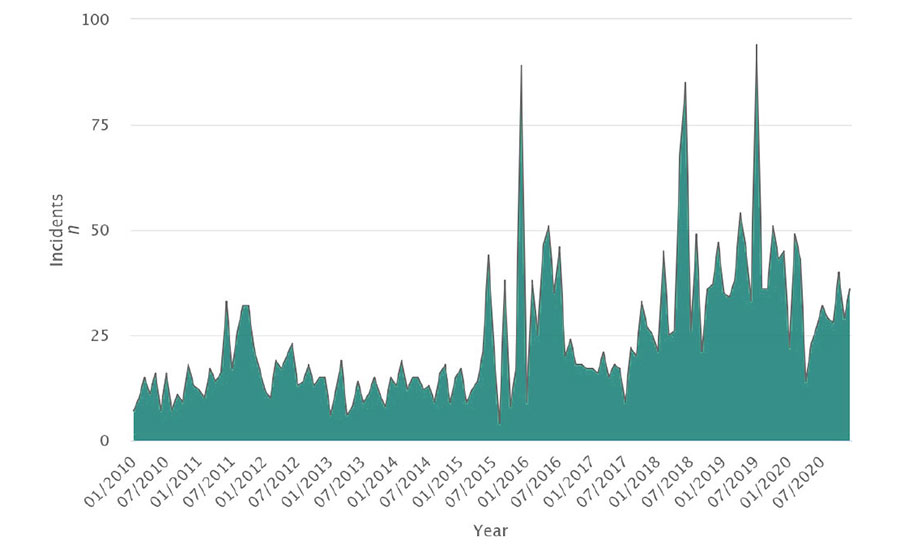

Foreign-body contamination continues to be a risk to the food and drink industry; despite having many food safety management controls in place, some still slip through these preventive measures. In 2019, there were 545 product recalls related to foreign-body contamination compared with 372 in 2020. While this shows a declining trend, this may be skewed by changes brought on by the COVID-19 pandemic. Looking at the data from 2010 to 2020, there is a rising trend (Figure 1).

Figure 1: Incident Trends According to Historical Data over 10 Years

So, why is this? Are the preventive measures in place failing, or are in-plant behaviors allowing contamination to occur? The attitude and behaviors of the team will impact the food safety culture in your factory. The food safety management system is underpinned by Hazard Analysis and Critical Control Points (HACCP). Observe how your HACCP team behaves: Is their norm to meet as a team or is this a technical function with others being informed of their decisions? The stronger food safety cultures will have the whole team engaged, ensuring employee knowledge of foreign-body hazards is widespread. The HACCP team identifies the foreign-body hazards and implements suitable controls. There are several pieces of equipment used to prevent intrusion by foreign bodies such as sieving, filters, magnets, optical sorters, metal detectors, and X-ray machines. There are also manual controls such as decanting products from their original packaging, opening bags, and visual inspections. Before any of these controls are implemented, it is vital that you know your raw materials and any inherent risks associated with each. As raw materials arrive at the manufacturer and the ingredients are checked, the performance of each raw material should be monitored based on the findings at intake and through customer complaints. The raw material risk assessment should identify performance risks, which you can know either from your own findings or from external databases, and then appropriate control measures can be put in place to manage the risks associated with the raw material.

Prevention Strategies

Consider using this simple four-stage approach to foreign-body prevention and look at how your systems can improve.

As suggested by the term “eliminate,” this is an opportunity to prevent a foreign-body risk from entering the factory. The next prevention approach is to “minimize” the risk where possible. This could be receiving raw materials in plastic containers instead of glass bottles, for example. If there has been no success in eliminating or minimizing the foreign-body risk, we then look to introduce procedures that “restrict” foreign-body hazards from entering some areas of the factory so that they are away from open product. Finally, the foreign-body hazards are “managed” using the most appropriate mechanical or manual operation to remove the foreign body during product manufacturing. This is also supported with a robust planned preventive maintenance (PPM) and inspection system to ensure the manufacturing equipment is suitable for use on a daily basis and an internal audit program to verify procedures are being followed.

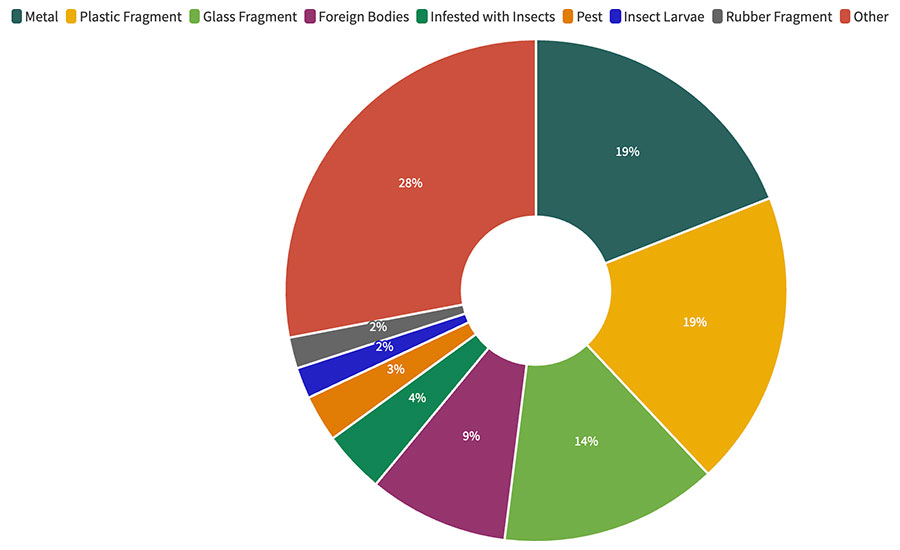

Consider the data in Figure 2, which shows the biggest challenge to the industry over the last 10 years is due to metal and plastic, followed by glass fragments and unspecified foreign bodies.

Plastic is used in many areas of a factory and sometimes unnecessarily, so let’s consider some areas where you may find plastic foreign-body hazards.

Figure 2: Specific Foreign-Body Hazards According to Historical Data over 10 Years

Intake

When walking around intake, look at the tray liners on which raw material suppliers send your products. Are they of a suitable thickness that when you decant the ingredients, fragments of the liner do not contaminate the product? Pallet wrap is rarely a source of contamination but should be well-managed at intake to ensure fragments do not enter the ingredients.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Decant

Where products are decanted from their original packaging, most commonly in plastic or paper sacks that can be also interleaved with plastic layers, there must be strict decanting procedures in place and good techniques applied to bag opening. Ideally, this task is conducted in a dedicated space and not opened in direct product contact areas. To see how well this task is completed, look at bags that have been put in the waste, as this will show if the operatives are doing this correctly when they are not being observed. When ingredients are suitable for sieving, this is a great way to catch any foreign bodies in the ingredients and any contamination from the original packaging.

PPE

Personal protective equipment (PPE) is often deployed in a range of colors to differentiate job roles and product handling. It has become the norm to enter a factory and then don an apron, gloves, and arm sleeves, regardless of job function. Is this really required for all roles? If workers will end up wearing wet or soiled coats, then perhaps an apron is necessary, but if they have a role that is weighing product into a tray, then perhaps it is not as necessary. Observe how people remove the PPE when they are changing and where this takes place, as it can be a known source of foreign-body contamination. As aprons are torn off, encourage the removal of PPE to be away from product contact areas.

Product Covers

We should also consider what hazard we are protecting the food from when tote bin covers or shrouds are placed on trolleys. If they are required to protect the food, ensure they are loosely fit and not stretched, which can cause a weakness in the plastic.

Product belts are often edged with plastic, but if they are not set up correctly and their tracking is off, they can rub on the conveyor roller covers and create shavings that go directly into product. Pre-start-up checks can pick up these issues to prevent contamination.

Packaging

Packaging is sometimes overlooked as a potential source of plastic contamination. Observing this operation is often enlightening about the risks packaging can cause. The packaging is heavy and often delivered in thin plastic bags that can easily tear when the bags are manually transferred to the packing area. They can be tightly knotted, which encourages poor bag opening techniques from the operatives as they tear the bags to access the packaging. Finally, the packaging itself can have slivers of plastic that fall into empty trays and are missed when product is put into the packaging, hence creating foreign-body contamination.

Where pots or trays are sealed, most line equipment has the function of detecting when packaging has been crushed. This function works well but also needs the correct behavior of the operatives to ensure that when this occurs, all debris is cleaned from the line to prevent any further contamination.

There are developments and innovations looking at how we can detect plastic contamination, but they are not common in the food industry. Therefore, Good Manufacturing Practices (GMPs) need to be robust to prevent plastic contamination.

The other foreign bodies identified are metal and glass. As all factory equipment is made from some type of metal, it poses a higher risk of contamination. Where metal is a known risk, it is good practice to create an equipment and composition-process map of the factory. This map shows each piece of equipment and details its metal composition. Therefore, when foreign-body contamination occurs and the metal piece is identified, you can narrow down which equipment it could have come from much more quickly. As already mentioned, glass should be eliminated in factories that do not pack into glass receptacles. Where this is not possible, GMP controls are required. Some measures could include rubber mats on the floor where glass is handled to prevent breakages if it falls or inversion of packaging to rinse or air-blow, which can dislodge any fragments of glass prior to filling. This operation usually occurs on a line that is covered to capture any contamination and is inspected using inspection trays on a regular basis. The best method for visually checking a line handling glass is with a flashlight, as any fragments will reflect.

Unlike plastic contamination, glass contamination can be detected by X-ray, and metal contamination by metal detectors as well as X-ray. However, there is a limit to their detection capabilities, which could explain why there are still many recalls as a result of metal and glass contamination.

Start-up checks and internal audits are a good indication of how mature a food safety culture is in a business. When we see a tick list that is 100 percent perfect, it is hard to believe that there are no areas that need improving. It is more realistic to see a few issues raised, which also shows there is a desire for continuous improvement. When you see perfect start-up check sheets, first assess if they truly represent the factory and then question what drives their behavior to have a 100 percent perfect start-up check. If checks and audits identify issues rather than indicate everything is perfect, you will see a behavior change so long as the issues raised are fixed or there is an explanation for why they are not being done. People will soon become disengaged if issues are continuously raised but they see that nothing happens when they are doing the right thing. Additionally, internal audits of foreign-body controls can identify areas of concern in advance of an issue by observing behaviors and adherence to procedures.

Practices to Prevent Contamination

Three key functions can help prevent contamination: engineering, operations, and hygiene. How they behave and work together can impact how well preventive measures are implemented. Starting with engineering, this function can create a significant risk to food safety if their practices are not well managed. Their work naturally involves removing parts to replace or fix equipment, and it is vital that they keep all parts secure during this operation and make sure they are not left behind on equipment. If there is a breakdown during production, and engineering can fix the equipment without causing a foreign-body risk during production hours, this reactive fix will proceed. PPM can reduce the likelihood of foreign bodies occurring, as the parts are replaced at the appropriate frequency, therefore reducing the risk of parts degrading. Whether engineering is called to fix a problem or it is a scheduled PPM, once the equipment is fixed, an inspection from engineering must take place to verify there are no foreign-body risks prior to handing the equipment back to production. During this assessment, it may be determined that production can go ahead and start using the equipment, or it may need to go through the hygiene team first. These decisions should all be documented in the form of a hand-back form. Other practices to reduce foreign-body contamination include the following: Engineering must have segregated PPE for working in the workshop and entering the factory to prevent swarf being transferred, as shoes are not always changed. Therefore, swarf mats are placed at the exit doors to capture any debris before personnel enter the factory environment. Finally, storage and toolboxes all need to be tidy; they should not create a potential risk with items stored on the floor or debris remaining in toolboxes. Engineering’s role in a food manufacturing facility is critical to food safety; if procedures are not adhered to, product recalls could result.

Operations is responsible for checking that their equipment is in good working order at the beginning of each shift and that all people on their shift are fit to work and wearing the appropriate PPE. If they identify an issue with equipment at the start of a shift or during production, they must stop the line and report to engineering, which assesses the fault and, if possible, it is fixed. Sometimes, damage can be monitored or belts can be trimmed to prevent foreign-body contamination. The operations managers are responsible to lead their teams, observe behaviors, and call out any behaviors that are done well or where they see a need for education to do the right thing.

The hygiene team examines all parts of the equipment when it is taken apart for cleaning, so they play a key role in reporting damaged equipment to the technical, operations, and engineering teams. A good approach is for hygiene to take photos of equipment for the technical, operations, and engineering teams to discuss a plan of action and close off the points raised by hygiene.

Communication plays an important role in preventing contamination, with clear handovers between shifts that provide an understanding of what has been reported to engineering to be fixed; this prevents the engineering log from receiving double entries from different shifts. Communication between engineering, operations, hygiene, and technical/quality departments about any issues found demonstrates a mature culture whose members work together to solve problems, find the root cause, and implement lasting change in their procedures to prevent reoccurrence.

Internal Results and Customer Complaints

On occasion, foreign bodies are identified internally, which I call “celebrations,” as they have been caught by the food safety management systems in place. However, it is what you do with these finds that shows how mature your food safety culture is. Some may acknowledge they have found something and are pleased that the system is working, while more mature cultures will take these finds and determine the root cause of the issue to prevent reoccurrence. Similarly, with customer complaints, it is common to complete an investigation of the specific complaint, but mature cultures will go one step further and use complaint trends and other metrics in the business to get to the root cause.

Foreign-Body Investigations

Much of the time, foreign-body investigations are led by the technical team, but I’ve witnessed teams who change the investigation lead between engineering and operations and have the greatest success at getting to the root cause of an issue and implementing changes.

When foreign bodies are equipment related such as metal and plastic, it works well to have engineering as the lead investigation team. But if the foreign body is related to PPE, as it is linked with people, an operations lead is most suitable.

As shown in Figure 3, each team’s role has a different function. For foreign-body investigations, technical and hygiene teams offer support, with technical providing new complaint or internal data, and hygiene reporting any damaged equipment and increasing their awareness of equipment that is identified as a potential source of contamination.

Let’s look at a theoretical scenario: A factory finds 12 metal pieces in products during the last 7 days. The product is a plain biscuit that is produced only on one line, but the raw materials may come from different bulk silos. First, the investigation team is established with a representative from technical, operations, hygiene, and engineering. It is decided that engineering will lead the investigation, and there are daily updates to review the progress of the investigation.

The engineering team identifies all metal pieces in terms of metal type, related equipment, and composition-process map; this helps them narrow down which equipment the contaminants could have come from. Meanwhile, technical and operations trace the flow of each metal to see what equipment and route the product came through.

The investigation team regroups to compare the two channels of information to see which equipment was used and which equipment contains the metal found. This is narrowed down to four potential pieces of equipment: mixer, dough cutter, flour silo 1 pipework, and hopper. The investigation team immediately inspects the equipment, but it requires a thorough inspection by hygiene and engineering. This inspection includes looking at all filters in the pipework to check for any debris, which may indicate the source of the foreign matter. Once they open the silo pipework, it is clear that metal fragments from the old, degrading pipes were the source of contamination.

Working as an investigation team can be very effective with the right people involved and focused on getting to the root cause of an issue.

Figure 3: The Roles of the Engineering, Technical, Operations, and Hygiene Teams

Engineering (Lead)

- Provide knowledge of all equipment and how it functions on-site

Technical (Support)

- Provide analysis and direction and report results

- Product traceability, to know which equipment and line were used

Operations (Lead)

- Provide access to equipment and have flexibility with the schedule to support investigations

- Guide the team to take actions and implement change

Hygiene (Support)

- Check equipment for damage and report to the management team

Conclusion

The foreign-body prevention methods at the manufacturing site require detection equipment to intervene but also rely heavily on the behaviors and attitudes of the workforce. From the raw materials arriving to assessing each process step in manufacturing, there is a need to understand the risks associated and how they can be controlled or mitigated. The stronger the food safety culture at the manufacturer, the lower the likelihood that issues will rise, as the company is one step ahead and looking to manage risks rather than a company with a weaker culture that is merely managing the hazard.

All data are provided by FOODAKAI, a food risk-monitoring, assessment, and prediction platform powered by Agroknow, a food safety intelligence company.

Nic Sharman, M.Sc., is director of Nic Sharman Consultancy Ltd., based in the UK. Nic supports food and drink manufacturers with a range of food safety and integrity tools so that her clients can achieve compliance with Global Food Safety Initiative and UK retailer requirements. Nic is an experienced auditor and conducts targeted foreign-body reviews for her clients and delivers food safety education online or in person.