Key Introduces ADR X Defect Removal System for Potato Strips

Key Technology has introduced the next-generation ADR X automatic defect removal system for potato strips, now featuring enhanced multi-spectral sensing, an updated mechanical architecture, and other additions.

ADR systems identify defects on wet potato strips and precisely trim the affected areas, recovering more usable product and thereby increasing yield and profitability.

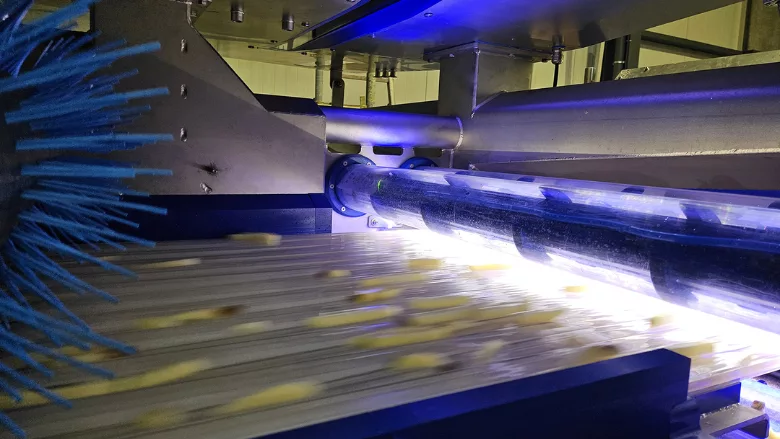

Building on the technology of Key’s previous-generation ADR systems, ADR X aligns, singulates, inspects, and trims both peeled and peel-on wet potato strips of various cut sizes.

ADR X features a series of new capabilities, including multi-channel sensing with advanced LED lighting and strobing to accurately identify challenging product defects like green discoloration. Multiple images of each strip are captured under different wavelengths and combined to create clear separation between the product and background, facilitating precise trimming decisions. A true-color user interface delivers clear visualization and intuitive operation.

Additionally, the new ADR X design maximizes hygienic operation in wet processing environments. The system architecture eliminates activity above the product stream, reduces flat surfaces, and integrates clean-in-place (CIP) functionality to protect product quality, simplify cleaning, and meet stringent sanitation requirements. Bearings and other key components are positioned for easy access to speed maintenance and support uptime in demanding production environments.

ADR X also features recipe-driven conveying and alignment mechanics that automatically adjust based on the selected cut size. Lane profiles and strip positioning are set via the user interface, allowing the system to respond to different strip dimensions without manual tuning and supporting repeatable performance across product changeovers. New endless, reinforced belts reduce belt stretch over time, eliminate the need for in-field welding, and allow belt replacement to be completed up to five times faster, which reduces replacement frequency and streamlines belt maintenance.

To maintain precise trimming as recipes change, the conveyor belt and cutter wheel operate with independent drives. The cutter wheel automatically repositions itself based on the selected cut size, allowing defects to be trimmed accurately while maintaining proper alignment throughout production.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Setup and maintenance tasks are simplified through single-point adjustment mechanisms for brushes and finger racks, which reduces setup complexity and speeds changeovers.

ADR X is available as a plug-and-play system that fits within a standard shipping container to support efficient delivery and onsite setup. For processors operating existing potato strip lines, ADR X can be installed as a direct replacement for previous-generation ADR 5 systems without requiring significant layout changes.

Key Technology: www.key.net