Key Unveils COMPASS Optical Sorter for Foreign Material in Leafy Greens

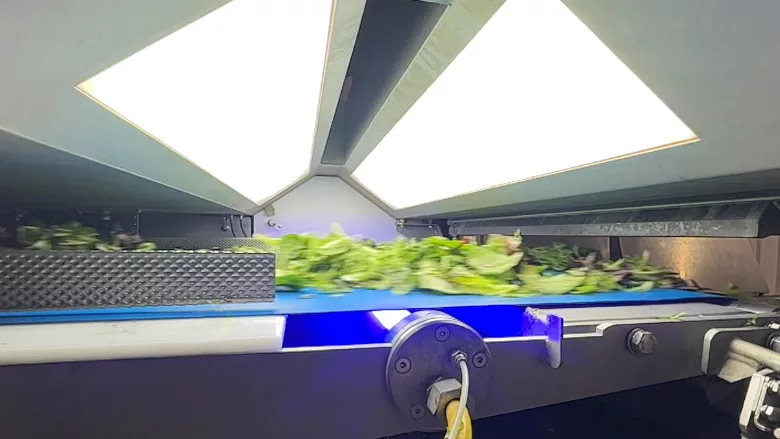

Key Technology has launched its COMPASS optical sorter, designed specifically for fresh-cut leafy greens. The belt-fed system combines high-performance foreign material (FM) detection and removal with gentle, hygienic product handling to help processors enhance food safety and operational efficiency.

Engineered for early-stage processing, COMPASS inspects product straight from the field and removes a wide range of physical contaminants—including dirt clods, rocks, sticks, insects, and animal parts—as well as product defects when sorting single varieties. The system is ideal for spinach, arugula, and other unwashed leafy greens, including salad mixes.

To simplify operation and reduce training time, COMPASS features recipe-driven controls and a touchscreen interface modeled after smartphone navigation. Operators can learn to run the system in less than 30 minutes, create new recipes, and switch between products quickly. Intelligent belt control maintains proper tracking automatically, minimizing downtime.

COMPASS offers customizable camera configurations with up to eight channels of multispectral sensor data. When equipped with Key’s Pixel Fusion technology, the sorter combines visible, infrared, and shortwave infrared data at the pixel level for enhanced FM and defect detection. An optional chlorophyll-sensitive channel further improves contrast between greens and contaminants.

The system addresses challenges associated with handling lightweight, moist leafy greens by integrating optimized infeed conveyors and optional air-assist systems for smooth product flow. Air knives at discharge help prevent good product from sticking or falling short.

Designed for sanitation and ease of maintenance, COMPASS features an open frame, sloped surfaces, and quick-release belt removal for fast washdowns. A clean-in-place system with spray bars and brushes maintains hygiene during production, while high-mounted camera windows and a dry-air boost system protect sensors in humid or refrigerated environments.

The sorter’s open architecture provides visibility into the product zone and accommodates integration with downstream equipment. For processors upgrading from Key’s legacy Optyx sorter, COMPASS shares the same footprint for seamless installation.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Each COMPASS unit includes Key Discovery software, enabling real-time data analytics and reporting to support performance monitoring and quality control.

Key Technology: www.key.net