Biosensor that Identifies Spoiled Meat Could Improve Food Safety

Credit: Shutterbug75 (Shutterbug75-2077322) via Pixabay

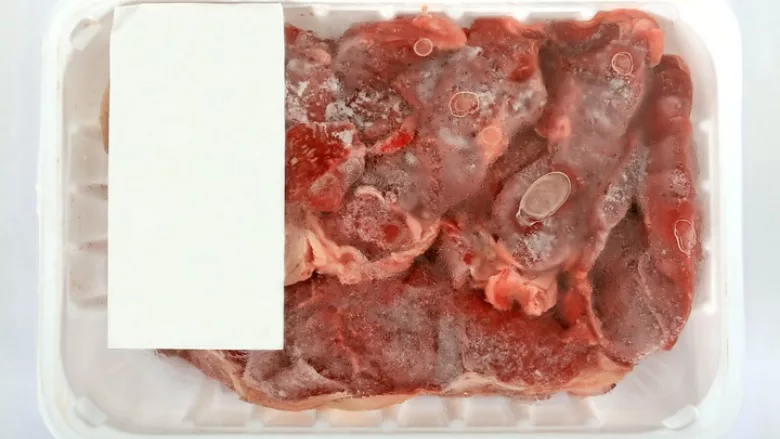

Researchers at Concordia University have developed an easy-to-use biosensor that indicates when meat has spoiled. The new technology has the potential to enhance food safety by preventing rotten meat from being consumed, which is important as recent years have shown that supply chain disruptions can put perishable product at risk of spoilage.

The inexpensive, reliable sensor was designed to recognize putrescine in beef, which is a type of biogenic amine (BA), a toxicological food safety hazard. Putrescine is the toxin responsible for the odor of rotting meat; its consumption can cause headaches, vomiting, diarrhea, and heart palpitations, and has been linked to an elevated risk of colorectal cancer.

The researchers note that there is a lack of regulation concerning safe putrescine limits in food, and that food handling practices are outdated leading to unnecessary putrescine intake. Additionally, conventional methods used to evaluate BAs in food are time-consuming, resource-heavy, and inconvenient for onsite use.

The newly developed sensor technology is not only cost-effective, but it can be easily and quickly used by anyone. It is also disposable and made of nontoxic materials.

The paper-based, synthetic sensor is based in a technique called cell-free protein synthesis, which involves the production of a protein using the biological machinery of a cell, without actually using the living cell. Specifically, the sensor uses the putrescine repressor protein PuuR, native to Escherichia coli bacteria, to identify the presence of putrescine.

In the laboratory, the researchers created a cell-free system that was producing PuuR. Putrescine was introduced to the cell-free system and the solution was then placed on a paper device. The researchers tested to see whether the presence of putrescine could be visually observed on the paper sensor under ultraviolet (UV) light, finding that the biosensor could detect the presence of putrescine after one hour. The sensor’s results were increasingly accurate as time passed, and were deemed highly accurate after four hours.

Next, the biosensor was tested on beef samples that were kept in a freezer, a refrigerator, and at room temperature. The sensor worked as expected, identifying very little putrescine in the meats kept at low temperatures, and very high levels of the toxin in the meat kept at room temperature. The sensor’s results were compared to those of a chromatography analysis and were found to be somewhat correlated.

The biosensor technology will not be ready for commercialization in the near future, but the Concordia researchers believe it has the potential to enhance food safety. Other sensor technologies to detect various food hazards, from foodborne pathogens to a history of improper storage, are also in development.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →