Global Food Safety Culture: North America

North America's food safety culture is characterized by diversity of thought; a proactive, risk-based approach; and high adaptability

Panelists Christian Blyth (Pathogen Specialist at 3M Canada), Marie Tanner (Senior Vice President of Quality at Dairy Farmers of America), and Lone Jespersen, Ph.D. (Cultivate SA) discussed three prominent features in North America's food safety culture: diversity of thought; a proactive, risk-based approach; and high adaptability.

Cultural Diversity

North America has a heterogeneous population across vast geographical variation, and is culturally diverse. In Canada, for instance, approximately 41 percent of the population is first- or second-generation immigrants. This introduces both diversity of thought and challenges to organizational management and culture. Given the high turnover in the industry, engaging these heterogeneities into a company culture—including seasonal workers and non-English speakers—becomes a business priority.

It can be challenging to integrate diversity of thought into business culture due to functional silos (hinder production and create tension among middle management), a lack or absence of leadership engagement on the floor, and product type. Collaboration is the key to fostering inclusiveness of diversity; for example, the operations team is likely to be supportive and should be involved, and buy-ins should be obtained from different functions and backgrounds. Ideally, cross-functional food safety ownership should happen on the floor, wherein production, food safety and quality (FSQ), sanitation, human resources, etc., gather and discuss at the frontline using a shared metric. To demonstrate that all the functions are connected can help prevent leaders from approving wrong food safety messaging that is based on information from a limited number of functions. Given the top-down decision-making that is prevalent in North America, leaders should also tour the factory to engage personnel on the floor.

To communicate food safety more effectively in a culturally diverse environment, seven considerations are described:

- Physical: Increasing proximity and creating relevance by bringing people into one physical environment

- Perceptual: Awareness that everyone is biased and has perceptual limitations

- Emotional: Being consistent and transparent in communication is the foundation of trust

- Cultural: All people operate on cultural assumptions

- Language: People in some parts of the world prefer one-on-one conversation, whereas others prefer group conversation; understanding this predilection helps establish effective communication

- Gender: Men and women often have different ways of communicating

- Interpersonal: Creating an open environment for communication is key.

To put these considerations to practice, a checklist can be created to track the removal of these barriers. The baseline is that communication should be based on organizational and regional culture, so that no one is left behind.

Preventive Approach

Up until 2010, the U.S. was used to a checkbox mentality, in which completed checklists and good audits equated to worry-free FSQ. Yet, auditors may not have examined the food environments and the effectiveness of the program; many details could be omitted. The year 2010 highlighted a shift in mentality in the U.S. that saw professionals adopting a preventive approach in food safety, marked by the passage of the 2011 Food Safety Modernization Act (FSMA) and the U.S. Food and Drug Administration's (FDA's) declaration of driving food safety culture. Canada underwent a similar phase in 2008 when a preventive mindset began to take hold, inspired by the 2008 Maple Leaf Listeria monocytogenes outbreak.

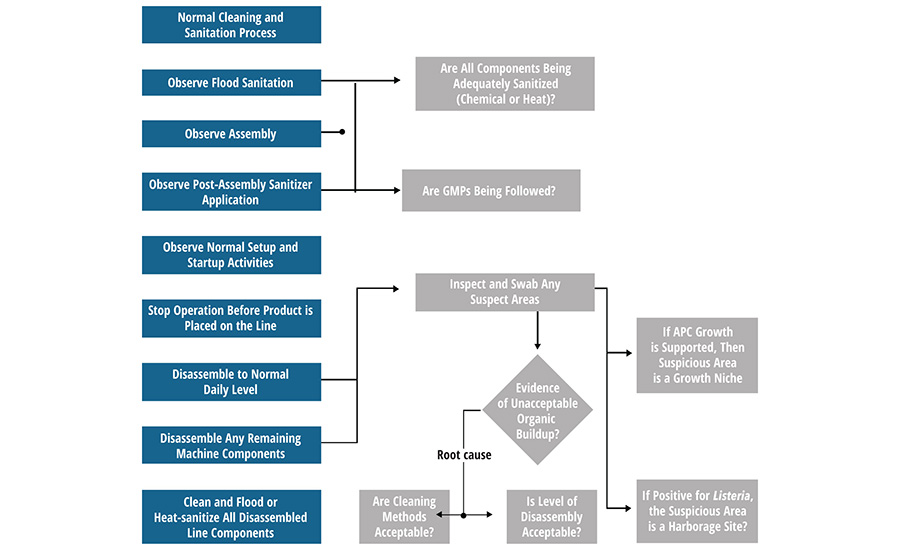

More standardization and regulation emerged across industry. In both countries, people began to have a greater awareness that not only frontline operators, but also senior leaders, had an impact on food safety. This new, preventive mindset is manifested in a shift in regulatory language that emphasizes a risk-based approach, in which people proactively look for possible environmental niches for foodborne pathogens and manage environmental contamination (Figure 1). This contrasts with the previous approach of end-product testing. In fact, panelists highlighted that they wanted to find positives during environmental monitoring—i.e., "if you do not find it, then you are not looking in the right place."

Knowing a pathogen's environmental presence can help a company put control measures in place so that the pathogen does not contaminate food products. Root-cause analysis is another method adopted by businesses to examine myriad events that lead to an incident. Documentation is the foundation of a program—i.e., "if you do not document it, then you did not do it." To reinforce the robustness of an environmental monitoring program (EMP), a business may work with a supplier that is certified by the Global Food Safety Initiative (GFSI).

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Figure 1. Process of Proactive "Seek and Destroy" Concept (Adapted from Malley et al., 2015)

Panelists compared reactive and preventive mindsets for three different roles. A plant manager will comply with FSQ assurance (FSQA) policy in a reactive mindset; but in a preventive mindset, they will conduct Gemba walks, ask people questions (e.g., what they are doing and why), and demonstrate clear engagement. Based on the feedback received, the plant manager will map out how to shift from the old mindset to the new one. Gemba walks are a powerful method that leaders are strongly encouraged to take on with cross-functional teams.

In the North America region, where food safety programs are normally driven from the top down, having managers take the initiative is crucial in building food safety culture. An FSQA leader in a reactive mindset tends to be audit-ready, and they will gather their team together only for external audits; however, in a preventive mindset, the leader acts as business partner by educating people on risks and owning a voice in the business' leadership team.

A production supervisor in a reactive mindset will simply check compliance; but in a preventive mindset, they will ask people questions and make sure that people are bringing up issues when needed. The supervisor also has the power to stop the line, if needed.

Adaptability

According to projects conducted by Cultivate, adaptability is the most challenging food safety culture dimension, with 76 percent of companies having it as their weakest cultural element. In North America, industry is generally well-adapted to new regulations, increasingly demanding customer requirements (which are always ahead of regulations), testing for emerging foodborne pathogens, and technology trends. Tailoring food safety objectives along with other competing objectives, such as operations and human resources, is crucial in enhancing businesses' FSQ capacity. When standards are not built into the company framework, challenges can ensue. The rising tide of expectations can also put a strain on businesses to meet all of the requirements.

An "adaptability paradox" about the North American food industry was delineated during the course of research. While businesses are often agile in adapting to changes, able to meet customer demands, and able to react to emerging issues and changes in leadership and programs, an inevitable drawback appears: the "flavor of the month" syndrome. Consistency can be compromised as chasing nimble adaptability, resulting in the misalignment of people and systems. Employees may experience change fatigue and disengagement. To avoid this "flavor of the month" syndrome, companies can pilot major changes in a few plants and, after these prove successful, they can be rolled out to the remainder of the locations.

Adaptability in North American industry is closely data-driven. Data is the source of knowledge. It informs investment and decision-making, and it guides improvement and policies. A next-generation data analysis was proposed, in which information seamlessly flows from test points to an actionable plan, and allows remote, real-time data access and monitoring (Figure 2). In other words, data is what makes the process more effective and impactful, and ultimately supports proactive, evidence-based decisions.

Figure 2. The Seamless Data Flow in Next-Generation Data Analysis

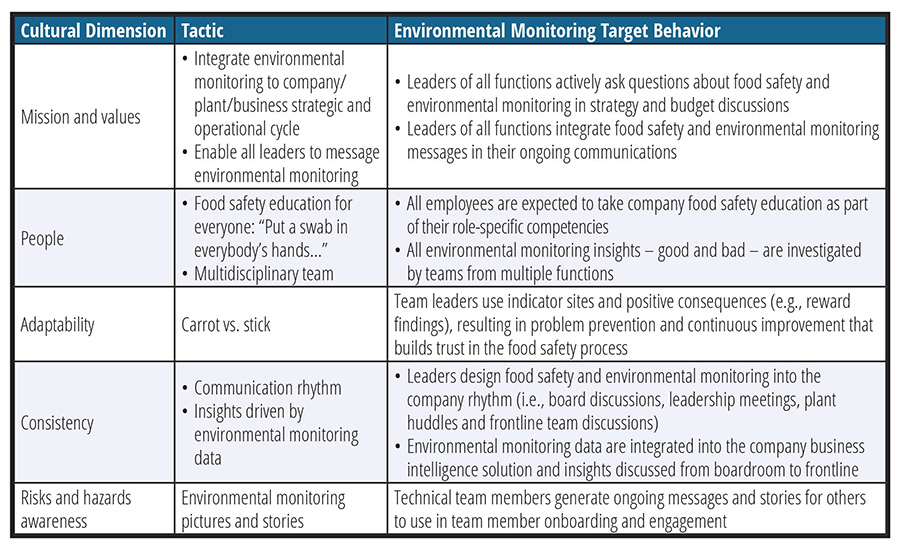

Behavior change, on the other hand, is driven by tactics and specific, corresponding target behaviors. For example, to enhance adaptability, the tactical approach of "carrot and stick" can be used to focus on positive consequences, such as rewarding findings in environmental monitoring (Figure 3).

Figure 3. Examples of Tactics and Corresponding Target Behaviors as Adapting Behavioral Change (3M and Cornell University, 2019)

Culture exists only when assumptions, values, and visions are shared. Given the high heterogeneities in the North American region, improvement of inclusion and effective communication are key enablers to transform food safety. It is noteworthy that North America has a robust, risk-based, preventive approach manifested in environmental monitoring. Adaptability is the most challenging culture dimension; despite the general agility in adapting to changes, the "flavor of the month" syndrome is prevalent, leading to change fatigue and misalignment. Consistency and adaptability can be joined by evidence-based, targeted behavior change.

Lone Jespersen, Ph.D., is a principal at Cultivate, an organization dedicated to helping food manufacturers globally make safe, great-tasting food through cultural effectiveness. She has significant experience with food manufacturing, having previously spent 11 years with Maple Leaf Foods. Dr. Jespersen is also a member of the Food Safety Magazine Editorial Advisory Board.

John David is Global Scientific Marketing Manager at 3M. He holds a master's degree in molecular biology and genetics and a bachelor's degree in biological sciences, both from the University of Delaware.

Sophie Tongyu Wu, Ph.D., is a Senior Research Assistant at University of Central Lancashire and a member of Cultivate SA. She leads a food safety culture improvement project at ten UK food manufacturing companies to collect organization-wide feedback for targeted action. Dr. Wu holds a Ph.D. in food science and technology from Purdue University and a bachelor's degree in biology from the University of Wisconsin–Madison.