Extending the applications of blockchain in the food manufacturing industry

Engineers at NIST have designed a secure method for interchanging parts design data using blockchain technology. While in development for discrete manufacturing and pharmaceuticals, the technology could be applied in the food industry for product design and development.

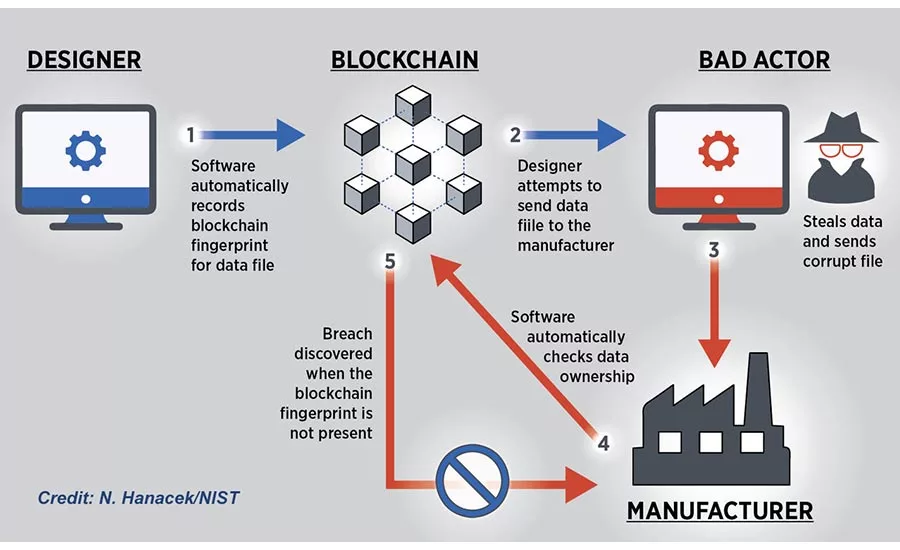

Chart courtesy of N. Hanacek/NIST

According to a new NIST (National Institute of Standards and Technology) report, blockchain—the underlying security system used in bitcoin and other digital currencies—is being used to provide not only tamper-resistant transmission of manufacturing data for making machine parts, but also perfect traceability of that data to all participants in the production process.

Protecting the intellectual property of machine part design as it travels among participants in an additive manufacturing process could have extensibility into food and beverage in two ways beyond the tracking and tracing of food products from supplier to final point of sale.

First, in keeping the discussion at the machine parts level, blockchain technologies could be applied to parts design or machine modifications as food processor, OEMs and their parts suppliers design or make changes to a machine to handle new processes or packaging.

Second, blockchain technology could be applied to new food product design. For example, a processor’s master chef will collaborate with clients’ chefs about new product recipes, processing, packaging, etc. In addition, product design teams need to produce new graphics and packaging—all of which need to be protected from prying eyes while each team member gets accurate and timely information. How does it work?

Blockchain is an expandable list of records, or blocks, each containing data representing an individual transaction by members of a network. Each block consists of a data set, time stamp, a cryptographic hash (a cybersecurity fingerprint) and the hash of the previous block, mathematically linking them together. Information in any block cannot be altered without changing all subsequent blocks and alerting record-keepers in the network that possible foul play has occurred.

According to the NIST report (Series 300-6) entitled “Securing the Digital Threat for Smart Manufacturing: A Reference Model for Blockchain-Based Product Data Traceability,” smart manufacturing requires that product data be shared and exchanged among numerous engineering applications and information systems, but all the information generated and shared in a product’s lifecycle needs to be protected from tampering, corruption and theft. It must also be totally traceable and time-stamped—and always up to date.

“In other words, if I’m a manufacturer making a part for a product and I receive the specs for that part from the designer who’s upstream in the process, blockchain ensures that I can trust the data actually came from that person, is exactly what he or she sent, and was not interfered with during transmission,” says NIST research associate and computer scientist, Sylvere Krima, the report’s lead author. “Because the chain is tamper resistant and the blocks are time-stamped, a blockchain is a robust solution to authenticate data at any point during the product lifecycle.”

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Why blockchain?

“What we didn’t put in the report is the work we had done before that,” said Krima. The goal was to ensure that no one tampered with the data throughout the product lifecycle. The problem was that not all formats make protecting the data easy. “We looked at things such as digital certificates/signatures, but one issue we had with digital certificates/signatures is the fact that not all the data formats support digital signatures,” says Krima. “So we needed a way to have that kind of signature outside of the file itself.”

Another problem is that not all file formats consistently support digital signatures, so tracking and tracing data alternations is difficult. Blockchain became the solution because it supplies a central repository or registry that contains all the information about exchanges—what was exchanged, who was involved and when the transaction happened, says Krima.

Simply put, as a repository blockchain registers can support most any data, such as CAD files, Word documents, emails and plain text, according to Krima. Importantly, besides holding the data, blockchain keeps track of everything about movement of the information, keeping it up to date and secure.

So could this technology be applied to the food and beverage applications previously mentioned? “Absolutely,” says Krima. “What we’ve done is exactly that kind of use case; it enables exchange among partners.”

This application of blockchain technology for design teams is moving into other industries besides manufacturing, including pharmaceuticals and autonomous vehicles, says Krima. The good news is the technology is relatively simple to implement and not at all cost prohibitive. Siemens is working with blockchain technology in other product design areas, according to Krima.