Factory of the Future – Industry 4.0 and Hygienic Design

Technology poised to reduce risk for product and workers

Hygiene in food production has always been a priority, even when production occurs under crisis conditions. While the world stayed at home during the COVID-19 pandemic and maintained social distance, the food industry had to find a way to ramp up production despite the dangers to its workforce of the highly contagious disease.

Due to the necessary close proximity required for some specific food processing industries, clusters of illness occurred with some degree of regularity. Although never mutually exclusive, the health of the food processing staff and hygienic design are now even more intertwined and interdependent. As we look to a sustainable future, we must use Industry 4.0 methodologies and marry hygienic design with enablers of business continuity such as heating, ventilation, and air conditioning (HVAC) design, production floor density reduction, increased data analysis, traceability, and repeatability.

This article will explore specific aspects of Industry 4.0 and how it relates to hygienic design. We will use examples of how our fictional food production facility, “FoodCo,” has adopted facets as part of their overall 5-year strategy. FoodCo is based in a single location. The company has been in business for 70 years and has grown steadily. FoodCo has adapted well to industry changes but has had to manage costs in their competitive market. They have acknowledged the opportunities that new technology presents to their business. Due to a relatively slow adoption of these technologies in their sector, they have identified a significant advantage in developing and implementing an Industry 4.0 strategy for their business.

Factory of the Future

So, what does hygienic design in the factory of the future look like? What factors need to be considered and what are the major constraints?

The factory of the future will:

- Have more automation

- Have better access to data

- Have better analysis of data

- Make better use of the data analysis

- Permit better decision making with more defined outcomes

First, to dispel some of the current myths. You cannot buy Industry 4.0 in a box. Buying a robot from the local robot salesman is not in itself Industry 4.0. Nor does connecting all your old equipment to the Internet realize the potential of Industry 4.0.

Industry 4.0 has been dubbed the fourth industrial revolution. As with the preceding three revolutions, it is the availability of technology and work practices rather than a specific playbook that defines Industry 4.0.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

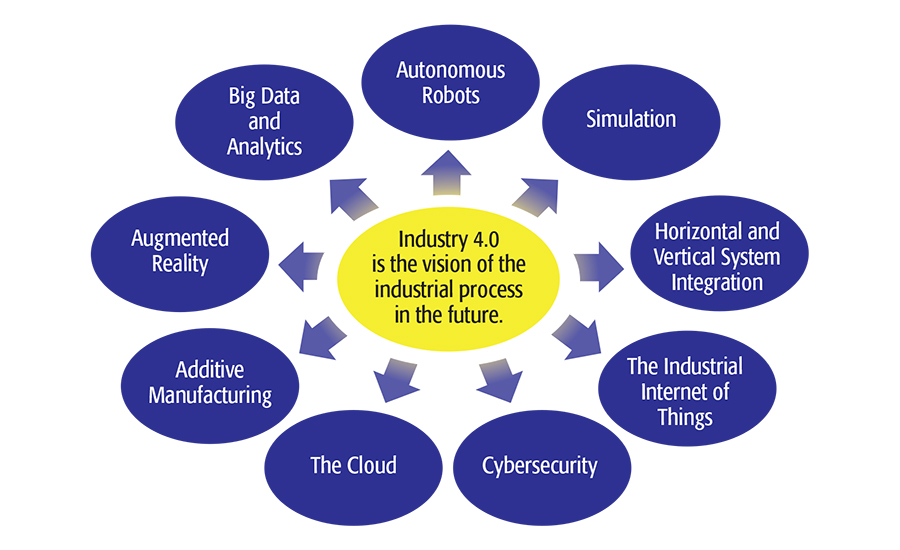

Industry 4.0 can be considered as a type of philosophy that has to be all-inclusive and company-wide for the principles to be effective and provide a positive business impact. But initiation and buy-in need to start at the top of the organization. Industry 4.0 can cover autonomous robotics, simulation, cybersecurity, Industrial Internet of Things (IIoT), the cloud, additive manufacturing, augmented reality, big data, and analytics (Figure 1).

Taken all together, this can be considered quite a mountain to climb. You don’t have to include all aspects of Industry 4.0, but you need to be clear before you start what you plan to adopt and why. The first step on this climb has to be education, quickly followed by a robust adoption strategy. If done correctly, it will make economic sense.

Whether referencing the European Hygienic Engineering Design Group Hygienic Design Principles, Codex Alimentarius, C.F.R. Title 21 Part 110, or the North American Meat Institute’s fact sheets on hygienic design of equipment, we cannot lose sight of the overriding principles and goals of hygienic design. It has to make sense financially and operationally and consider the following from a safety perspective:

- Facility design

- Equipment design

- Sanitation practices

- Good Manufacturing Practices

- Education

In a highly regulated industry, hygienic design is well-understood. However, best practices are continually evolving based on industrial lessons learned but also in response to changing consumer needs. Increased demands for convenient food and reduced cooking time increase the chance of microbial infection, as not all microbes are killed in the cooking process. Reduced salt/preservative requirements can increase the likelihood of spoilage. An epidemic or pandemic can impact entire food production philosophies and practices. Social distancing is now the norm. There is an increased focus on staff health. So, as this evolution continues, how can you pick your fights and measure accurately the impact of the changes? This is where advances in technology conveniently covered by the umbrella of Industry 4.0 can help.

Having access to real-time information regarding the performance of equipment such as HVAC systems and their filters, pressures, etc. will enable you to ensure that they are operated and maintained in a manner to minimize personnel and food safety risks.

Rapid-method technologies are continuously being developed for the testing of microbial or foreign material contamination so that more data can be collected immediately and instantly trended, and actions can be taken.

These are just two simple examples of how hygienic design and Industry 4.0 relate to each other.

Settling on an Industry 4.0 Strategy and Plan

Like any good project, Industry 4.0 must start with a sound strategy and plan. This must be driven and endorsed by the leadership of the company. The communication of this strategy cannot be underestimated. The most common question around Industry 4.0 is, “Will robots take my job?” This is an understandable concern. However, more often than not, robots actually support safer working, remove repetitive, monotonous tasks, increase output production per square foot, and empower staff to assume more meaningful tasks. Communication is the key.

Selection from a Menu

So, how do you select from a menu of options? What we have done here is select some of the key aspects that are both immediately relevant to both the food industry and specifically hygienic design and operation under the headings:

- IIoT and the Connected Factory

- Big Data

- Autonomous Robots

- Augmented Reality

- Data Analysis

1. IIoT and the Connected Factory

This refers to the connection of sensors and equipment to a local network, wireless or hardwired, for the purposes of either direct control or data acquisition. This sensorization and connection is a typical starting point. However, a word of caution. Installing sensors everywhere or figuring out how to connect old analog devices is not in itself effective. There needs to be a reason and strategy for collecting these data. A couple of relevant examples are detailed below:

FoodCo installs a new handwashing regime

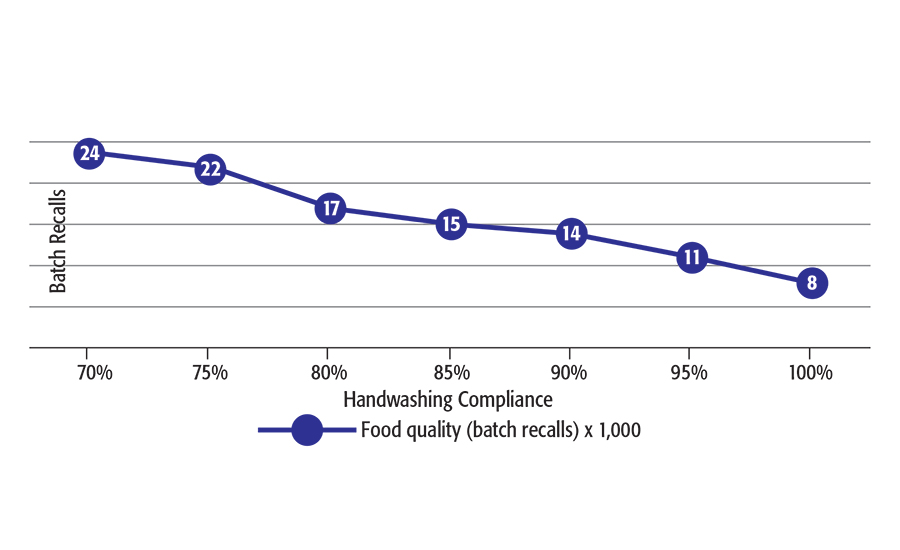

FoodCo installs a new hand hygiene regime that monitors the time it takes to wash hands, frequency, compliance, etc. By connecting this new monitoring system, FoodCo can analyze adoption patterns and compliance percentages (Figure 2). These data can be correlated with other outcomes, such as productivity, recalls, and nonconformances. In this way, FoodCo can analyze the effectiveness of the new system and the objective returns on its installation.

FoodCo installs a sensorized planned predictive maintenance system

FoodCo had an adequate preventive maintenance program. However, there was growing concern about the impact of such occurrences as wearing of metals and food-grade plastics due to the misalignment or vibration of equipment. Their goal was to add more early warnings to their maintenance practices to reduce the risk of such contamination.

By connecting additional sensors, connecting old sensors, and integrating them into a digital twin1 and predictive maintenance program, FoodCo was able to reduce downtime, reduce cross-contamination due to failing equipment, and implement a predictive maintenance regime. One of the significant advantages of the predictive maintenance regime is that you take down the unit only when required. The standard annual preventive maintenance practice can be scheduled for when it is needed rather than when it is timed. Correspondingly, this will reduce the volume and frequency of external contractors on-site. This predictive maintenance regime coupled with the integration into a digital twin will have significant positive input into the hygienic principles of FoodCo’s factory.

2. Big Data

Closely related to the IIoT is the concept of big data. Like all the aspects of Industry 4.0, big data come with a health warning. Data for the sake of data are no good to anyone. “Rubbish in, rubbish out” has never been a truer statement when it comes to big data. The accumulation of data without a goal is not advised. You must ask yourself what the data are for and how will they affect your decision process. The key with data is to know succinctly what you require from the data.

FoodCo incorporates big data analysis to implement artificial intelligence

FoodCo has used the big data that they have acquired from their existing equipment and new vision and scanning system to implement their artificial intelligence (AI) carcass-recognition software. This system continues to learn from each iteration of the data set to accurately identify and locate specific cuts on the carcass. Through this AI machine learning, it can also identify patterns in hygienic performance and display the outcomes and predictions on an easy-to-use dashboard template.

3. Autonomous Robots

The most visible representation of Industry 4.0 is the robot or cobot (collaborative robot).

Collaborative robots are complex machines that work hand in hand with human beings. In a shared work process, they support and relieve the human operator. Robots, on the other hand, are typically more expensive and guarded/isolated from human interaction during operation.

The application and use of robotics can be considered divisive. Do robots replace human operatives for certain tasks? In many cases, the answer is yes. But looking under the hood a little more, the application of cobotics can actually supplement rather than supplant workers. In the increasingly competitive food production industry, manufacturers must innovate to maintain margins and remain productive and profitable.

With the additional considerations of social distancing and health of workers, the implementation of robotics and cobotics has become more relevant. Early adoption of robotics/cobotics could be the difference between continuing in operation and shutting down.

Consider the example of a typical boning line in a meat processing plant. The work is labor-intensive, with floor personnel typically standing within one meter of each other. There is no room in the facility to space the equipment, and reduction of the workforce will essentially reduce production proportionately. By introducing a cobot/robot at intermediate positions, personnel safety is maintained, monotonous/repetitive tasks are removed from the operators, the capital expenditure of building a new process line (or worse, building a new facility) is avoided, and cobots/robots also reduce the risk of exposing the product stream to foreign material such as pet hair, lint, and even perspiration, which are not entirely removed by donning a smock and a hairnet.

Robotic Adoption

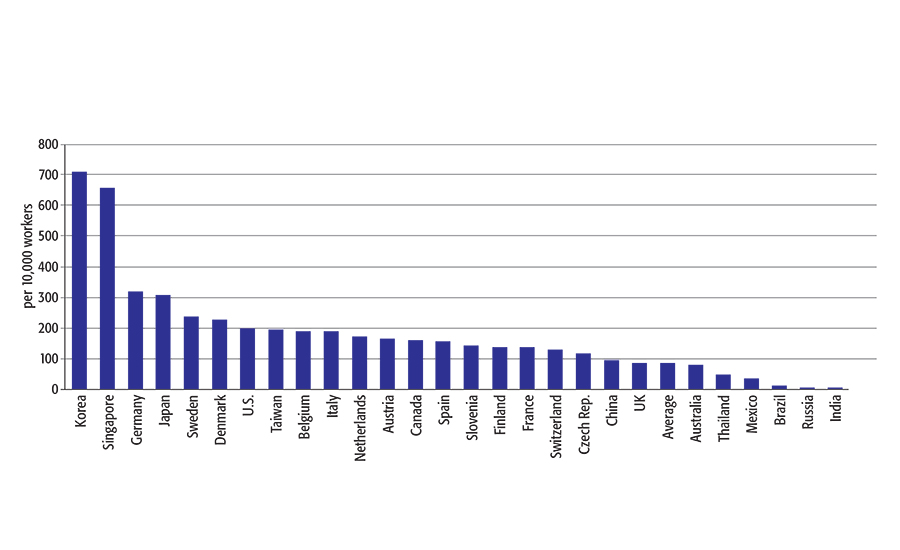

Figure 3 shows robotic adoption from manufacturing. This takes into account all manufacturing activity and not just food production. The use of robotics in food production has mostly focused on the end-of-line activities such as palletizing, packing, and stacking. However, as robot original equipment manufacturers develop more innovative and hygienically compliant robots, the potential for use upstream in the food production area grows. The Food Safety Modernization Act acknowledges that about 48 million people in the U.S. (1 in 6) get sick, 128,000 are hospitalized, and 3,000 die each year from foodborne diseases, according to recent data from the U.S. Centers for Disease Control and Prevention (CDC).2 For the most part, CDC would consider these outcomes to be preventable. The deployment and integration of robots in more upstream food production activities is part of this ongoing prevention strategy and guidance.

Robotics and cobotics adoption has been relatively slow in Canada, the U.S., and Europe. You can see from Figure 3 that Canada and the U.S. lag behind leaders in adoption South Korea, Singapore, Germany, and Japan.

FoodCo installs three new cobots

Following a time-and-motion study, FoodCo has installed three new cobots within its facility. In an extended packing line, FoodCo was presented with the challenge of increasing production and uptime while establishing a greater than two-meter distance in line with COVID-19 guidelines. Along this complex processing line, FoodCo was able to stagger the deployment of cobots. The cobots were monitored and tended by the operatives on the line. This ensured proper handoff at each substage in the process. The two-meter distance was maintained and production increased.

4. Augmented Reality (AR)

AR has been defined as “a technology that superimposes a computer-generated image on a user’s view of the real world, thus providing a composite view.”

The application of AR within the food processing industry has some significant advantages. If we look at the statistic relating to foodborne illnesses and the origins of these illnesses, a large contributor to this contamination is poor hand hygiene and basic hygienic practices.

Two particular groups can be identified as areas for improvement. The first is new staff on the floor. AR gives the opportunity to provide an immersive training program for new operators. AR can bring them close to activity that they will be undertaking without risking contamination during the learning curve. The second group is external contractors, who would typically be brought in to repair/fault-find/maintain production equipment. Although industry standards would define the practices they should adopt, they will not be used to the day-to-day discipline of hygienic behavior. With the help of AR, on-site operatives can be directed by remote contractors through the AR process to fault-find/maintain/repair a significant majority of the equipment failures that would be experienced. By having more immediate response, downtime can be reduced. And more importantly, from a hygiene point of view, contamination risk is reduced.

FoodCo installs an AR maintenance regime

FoodCo had experienced considerable downtime associated with maintenance calls and response times. As part of the root-cause analysis, they identified that 70 percent of the downtime activities could have been resolved within 30 minutes of the fault and that maintenance calls were affecting both production and contamination and cleaning times postfault. When FoodCo was purchasing new equipment, they decided to include an AR system in their specification. This also included a training module for all maintenance staff. When this new equipment was installed, the maintenance team was able to use the augmented reality to quickly fault-find and resolve the majority of the issues. This reduced the amount of downtime and number of contractor visits.

5. Data Analysis

With the ability to connect and collect data from a wider range of equipment, devices, etc., the opportunity for extensive data analysis is growing significantly. Data must be treated and stored appropriately. The availability of these data for analysis can increase traceability, repeatability, and continuous improvement in the food manufacturing industry.

Conclusion

This whistle-stop tour of the different facets of Industry 4.0 can seem quite daunting. There is no silver bullet, no “out of the wrapper” solution. The adoption of the principles must be clearly laid out in a strategy and road map. Education and communication cannot be underestimated, and the winning of hearts and minds can be as challenging as deploying multifunctioning cobots on an assembly line. However, the opportunity for real improvement and future-proofing of food production is real and tangible.

References

1. A digital twin is a dynamic virtual representation of a physical object or system, usually across multiple stages of its life cycle. It uses real-world data, simulation, or machine learning models, combined with data analysis, to enable understanding, learning, and reasoning. Digital twins can be used to answer what-if questions and should be able to present the insights in an intuitive way.

3. www.theatlantic.com/sponsored/vmware-2017/augmented-reality/1584/.

Diana Bennett, P.Eng., is vice president of operations for Malone Group, Canada, and has 30 years of experience in design and project management within the food industry. Diana also trains engineers, maintenance personnel, sanitation teams, and quality assurance professionals on clean design for food plants.

Tim Noone, B.Eng., is Malone Group’s projects director, a role with responsibility for major projects as well as leading the company’s research and development program.

Sam Tinsley, M.Sc., leads Malone Group’s Discovery 4.0 Project initiative. She is a nonexecutive director of Meat Business Women, the global progressive movement for women working across the meat industry.