Use, care and maintenance of cleaning tools during the pandemic and beyond

According to the CDC, one of the top-five contributing factors of foodborne illnesses in the U.S. has been associated with the use of unsanitary equipment and utensils during food handling and preparation. Tools for cleaning a food processing facility or machinery, if not adequately managed, can become vectors of key contaminants such as micro-organisms, allergens, and extraneous matter, which may eventually jeopardize food safety and quality.

To support the argument, a 1990 UK government-funded study revealed that 47% of the cleaning equipment and tools swab-sampled at a food production site had tested positive for Listeria monocytogenes. Therefore, in order to prevent or significantly minimize cross-contamination incidents within a food plant, proper selection, storage, cleaning, care, and maintenance of cleaning tools becomes absolutely critical.

Choosing the right tool for the cleaning task

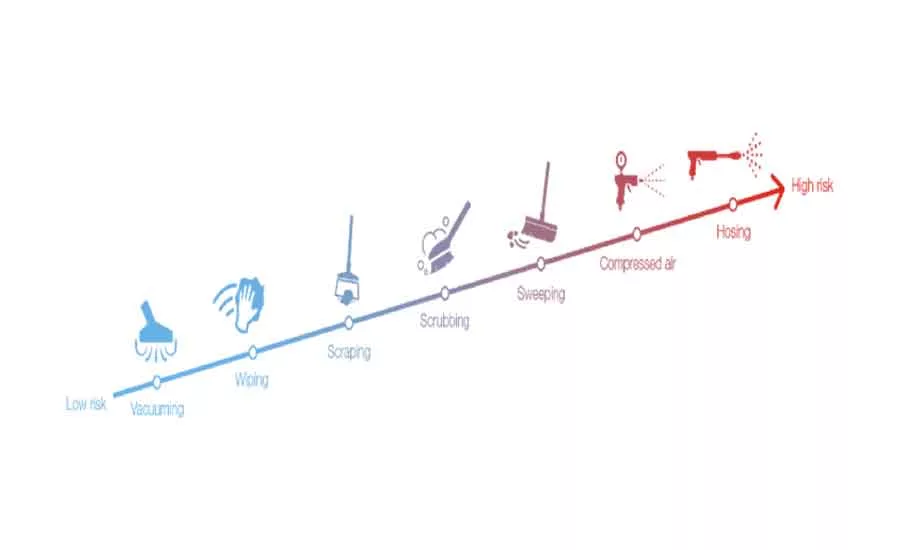

Whether a site conducts dry-cleaning, wet-cleaning, or both, tool selection is a key starting point, because cleaning by itself may enhance the spread of contaminants during removal of such soils from a surface. As illustrated in the graphic on the next page, each of those cleaning actions can pose a certain level of risk.

For instance, it wouldn’t be effective to use a soft-bristled brush to remove tough grease from equipment parts. Instead, use a stiff-or medium-bristled scrubbing brush on the part submerged in a detergent water bath to avoid aerosolizing contaminants.

Some other factors that may influence the choice of cleaning equipment are as follows:

- Don’t use stiff-bristled brushes on, say, food preparation tables constructed of sensitive stainless-steel material, as these may scratch surfaces and make them more unhygienic over time.

- Special application tools could be needed to clean hard-to-reach areas, such as the use of condensation squeegees with telescopic handles to access high walls and ceilings; angled brooms with ergonomic handles to remove debris from corners and low-lying junctions; detail-brushes to clean narrow gaps, nooks, and crannies in an equipment piece, etc.

- Drain brushes should be made of durable construction as they should be able to withstand harsh chemicals, heat and mechanical action that may be necessary during deep cleaning of uneven concrete surfaces.

Defining cleaning and storage protocols

We recommend adequately cleaning a new tool before use (but after removing any stickers), and thereafter, clean, at minimum, after every use. Just like equipment and facility areas, cleaning tools are also environmental surfaces. In general, if a brush or a scraper is used on food-contact surfaces like trays or equipment surfaces, the tools must be adequately cleaned and sanitized before and after use. If cleaning equipment such as squeegees and brooms are used on non-food contact surface like floors and walls, they should be regularly cleaned, periodically disinfected, and rinsed properly with clean water.

Tool cleaning considerations would typically involve, at the least, the following important elements:

(i) Assessing TACTER parameters required for soil removal – These are: Time required for chemicals to work on a tool surface; Action by way of mechanical agitation or scrubbing; Chemical concentration and pH; Temperature of the cleaning solution; Employees trained to do the job; and Resources such as other cleaning tools and sanitation aids.

(ii) Creating a risk-based cleaning schedule – even for the cleaning tools themselves, along with providing key details on how to clean, frequency of cleaning, verification and monitoring, and allocating the employee(s) responsible for the tasks.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

(iii) Ensuring that cleaning steps are understood by employees - For a wet-cleaning operation, this may include: disassembly of equipment and dry-cleaning to remove debris; pre-rinsing surfaces with potable water from top-to-bottom; applying detergent or foam from bottom-to-top; post-rinsing with potable water; post-sanitation QC inspection; and sanitizing, assembling, and drying the equipment, followed by a pre-operational inspection.

Additionally, in order to minimize the risks of cross-contamination, the cleaned tools should be stored properly on racks or shadow boards:

- With heads down that are off-floor, and distant from other tool handles;

- In a single row so that condensate from tool above does not drip on the tool below;

- That are regularly cleaned and sanitized, as appropriate.

It is vital to regularly inspect and replace damaged tools. Worn-out bristles, a badly chipped plastic block, a broken or taped-up handle, and deep cracks are some of the tell-tale signs that it’s high time you should replace a tool.

Evaluating the priorities during COVID-19

The ongoing COVID-19 pandemic has heightened the need for enhanced hygiene and sanitation within food plants. This has been principally to prevent any possibilities of SARS-CoV-2 virus transmission between employees through touch contact surfaces, such as hand tools. However, it’s also important to note that unlike the noroviruses, this coronavirus does not lead to a foodborne illness. Nevertheless, in the interest of occupational health and safety, some of the following precautions need to be taken:

- Clean and disinfect tools before and after use, and when transferred from one employee to another. Follow manufacturer’s instructions and use disinfectant that is EPA-approved to work against the SARS-Cov-2 virus.

- If a manufacturing facility is to be re-opened after a shut-down, tools for conducting a thorough deep-clean are required.

- In addition, follow WHO/CDC guidelines of washing hands, maintaining necessary respiratory etiquette, social distancing norms, and quarantining if sick.

Manual cleaning tools still remain a necessity

Automated systems may not be able to clean parts that aren’t CIP-able. Besides, CIP systems and components (e.g. spray-balls) also may need a periodic tear-down, deep-cleaning, and verification. In such situations, manual cleaning with hand tools may be the sole practical option. Hence, the role cleaning tools play in maintaining a sanitary environment within a food processing facility cannot be underestimated.