How RFID technology can help increase confidence in food safety

Prior to the COVID-19 pandemic, conscious consumerism was on the rise in a big way, forcing a shift in the way food supply chains function. Consumers want supply chain transparency, robust product information, the assurance of food safety and swift action when a recall occurs.

Now, in the age of pantry-loading, fast-food delivery and outdoor dining, satisfying a deeper need for information will be the key to securing consumer confidence and trust in our new pandemic-influenced reality. Core to delivering on what consumers want is enabling improved food traceability.

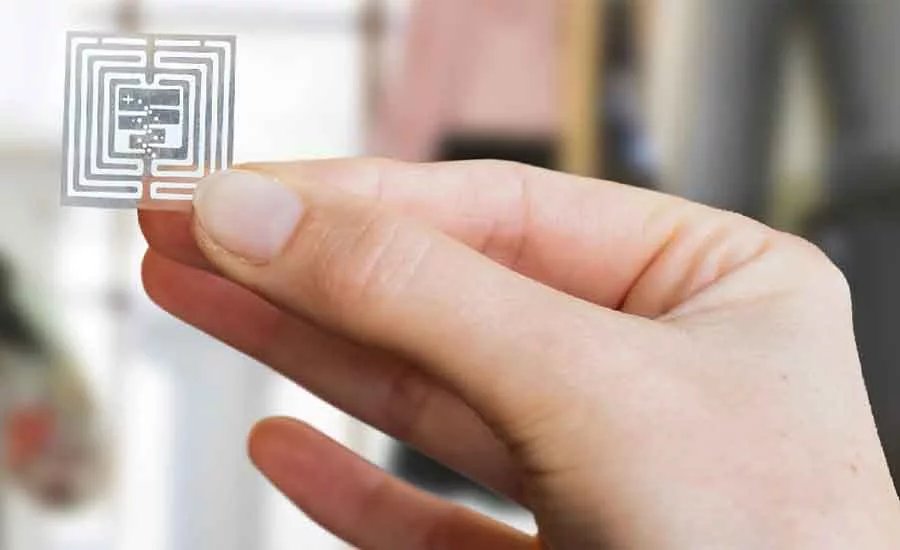

Recognizing the need to improve supply chain visibility and, ultimately, traceability, foodservice companies are beginning to explore the use of radio frequency identification (RFID) technology to trace products throughout the supply chain and gain operational efficiencies. RFID-enabled efficiencies can cut labor costs by as much as 50% in the food supply chain, according to Avery Dennison. With equipment and label costs falling further each year as adoption ramps up (labels cost around five cents each now compared with 25 cents in 2008), many companies believe the investment can deliver significant returns.

RFID in the supply chain is nothing new—it has been used in retail for more than a decade, particularly in the apparel industry, to improve inventory visibility and gain fulfillment efficiencies. Levi’s, Nike, Macy’s and Target are among the most vocal supporters of RFID and have used it to help make their supply chains more agile. They’ve cited RFID as a foundational technology necessary to support e-commerce.

Learning from the successful implementations of RFID in retail, members of the Foodservice GS1 US Standards Initiative, a collaborative group of foodservice supply chain partners, are testing RFID to gain similar efficiencies and better serve their guests. RFID tags and readers add efficiency to the supply chain because they do not require the same line-of-sight scanning as barcodes. They can also enable the collection of information in real time and the ability to pinpoint where products are across the supply chain. Plus, in a world of prolonged social distancing due to COVID-19, there exists an opportunity to leverage RFID technology to create more contactless options to procure food.

RFID and Traceability

Looking toward the future of traceability, food companies are going to need to align on a common way to communicate product data to close any gaps in information in the supply chain. Global GS1 Standards play a key role in traceability as well as RFID implementations—having consistency in data exchange and product and location identification is critical to tracing products from farm to fork.

Good traceability starts at the source, where globally unique identifiers like Global Trade Item Numbers (GTINs) should be used on products in lieu of proprietary numbers that could create confusion across external systems. GTINs can be encoded into RFID tags along with additional product information, similar to how they are encoded into barcodes. In the food industry, case-level barcodes have traditionally served as the key point where information is connected to the flow of the product. Not only can RFID can help companies capture more data efficiently while products are in transit, it can streamline and validate the loading and receiving processes. Extended data such as batch number, lot number and expiration date are already becoming must-have information in the supply chain—RFID has the potential to take this further as tags can hold far more data than barcodes. This can enable full product provenance and enhance visibility through greater automation.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

RFID and Inventory Visibility

When RFID tags are used, all supply chain partners that have RFID readers can enhance their real-time view of the product as it moves from stop to stop. Operators can then leverage RFID readers in their facilities to understand what they have available to sell. According to the Auburn University RFID Lab, RFID can raise inventory accuracy significantly, from 63% to 95%.

RFID is valuable for a foodservice operation simply because it reduces inventory uncertainty. For example, if an RFID reader is placed in a restaurant’s refrigerator, the operator will automatically know when there is a spike in a particular item being used, because the reader automates the transmission of inventory data. The operator sees in real time how much product is available to fulfill consumer demand. From a food safety perspective, RFID can play a role in helping operators intercept potentially harmful food before it reaches their guests because they have access to updated intelligence on what’s in stock and can take precautionary measures faster.

There are some inventory management differences between the way RFID is used in retail and how it may be used in foodservice. In foodservice, tags will be applied at the case level, instead of to individual items like in retail, simply due to the nature of how products are stored and transported. For example, there is no benefit to individually tagging a beef patty in the same way that there is in tagging a t-shirt in retail.

RFID and Our Contactless Future

RFID could be a key tool in our new normal, as it reduces the reliance on manual processes. For example, warehouse staff can more appropriately distance if RFID is used for cycle counts, and they can be freed up to perform other tasks. According to the Auburn University RFID Lab, cycle count times can be cut up to 96% when RFID is used. What usually takes three to four hours can be done in a few minutes without the need to manually scan line-of-sight barcodes.

As COVID-19 continues to affect the way we obtain food, the food industry has been forced to innovate faster and is becoming more digitally focused on the consumer-facing side as well. For many operators, this may be the only way to survive.

The efficiencies gained through using RFID can fuel evolving food distribution models. RFID can play a role in innovations from ensuring location-based accuracy for last-mile food delivery, to powering healthy vending machines while cafeterias in essential locations like hospitals remain closed.

Ultimately, while innovation was already a priority for many food companies prior to the pandemic, the complete shift in consumer behavior has become an undeniable catalyst for enhanced traceability, inventory management and contactless options. Look for RFID implementations to play a key role in the industry’s drive to enhance consumer confidence.