Home » Keywords: » preventive controls

Items Tagged with 'preventive controls'

ARTICLES

Supplier preventive controls are a key element of food safety assurance in the end-to-end supply chain of food manufacturing to retail foodservice and sales

Read More

Food Safety Objectives: The Nexus among Preventive Controls, Validation, and Food Safety Assurance

The Food Safety Objective concept is compatible with the foundational precepts of process validation

February 6, 2023

Dairy HACCP Through the Years

The dairy industry has seen many regulatory changes, including the incorporation of the FSMA Preventive Controls Rule within the Pasteurized Milk Ordinance

October 11, 2022

Food Safety

Do third-party audits need a revision?

Food and beverage companies often view audits as something to pass instead of necessary improvement tools

September 29, 2020

Food Safety

How processors are adapting to FSMA in its early years

What food and beverage manufacturers need to know to stay in compliance

September 1, 2020

Food Safety

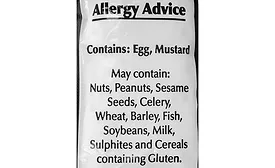

How to manage food labels to ensure allergens are clearly noted on any product

Use of the wrong package or label is one of the most common causes of allergen recalls

August 4, 2020

Food Safety

FDA moves to in-depth analysis after romaine field tests didn’t find outbreak strains

'Root-cause' investigation will help determine needed preventive controls

January 21, 2020

Never miss the latest news and trends driving the food safety industry

Newsletters | Website | eMagazine

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing