Larry Keener CFS, PA

Larry Keener, CFS, PA is President and CEO of International Product Safety Consultants. He is also a member of the Editorial Advisory Board of Food Safety Magazine.

ARTICLES

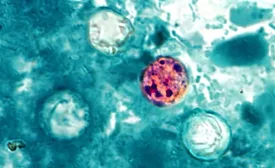

Unresolved or inconclusive epidemiology for several outbreaks offer compelling case studies of the challenges and risks posed by Cyclospora in food supply chains

Read More

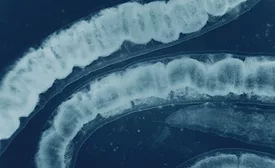

Hydroxyl Radicals for a Radical Advantage in Food Processing Hygiene: A Survey of Biocides Used by the Food Industry—Part 2

Biocidal chemicals and other physical/chemical techniques may be used together, in a strategic manner, to achieve an overall improvement in plant hygiene

February 12, 2025

Hydroxyl Radicals for a Radical Advantage in Food Processing Hygiene: A Survey of Biocides Used by the Food Industry—Part 1

The use of hydroxyl radical air cleaners is a unique and valuable addition to the food industry's methods of minimizing pathogens in air and on surfaces

December 19, 2024

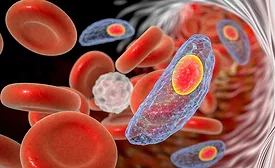

Medically Important Foodborne Parasites: A Consequential Challenge for Food Safety Assurance

Foodborne parasitic diseases are often overlooked in food safety control schemes, even though they are known to pose a severe threat to human health

April 11, 2024

Food Safety Objectives: The Nexus among Preventive Controls, Validation, and Food Safety Assurance

The Food Safety Objective concept is compatible with the foundational precepts of process validation

February 6, 2023

Foodborne Parasites: An Insidious Threat to Food Safety and Public Health

Often neglected in risk assessments, foodborne parasites deserve more scrutiny—and prevention

October 18, 2021

LEEB

Winning the Fight against Pathogens on Spices

Low-energy electron beam (LEEB): A breakthrough microbial reduction technology

April 15, 2021

Never miss the latest news and trends driving the food safety industry

Newsletters | Website | eMagazine

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing