Dairy HACCP Through the Years

The dairy industry has seen many regulatory changes, including the incorporation of the FSMA Preventive Controls Rule within the Pasteurized Milk Ordinance

Shortly after I started working as a Quality Assurance Manager two decades ago, one of the supervisors in production told me that Hazard Analysis and Critical Control Point (HACCP) programs would not be around in the years ahead, as they would eventually become obsolete. Some 20-plus years later, HACCP is still alive and well. Many of the techniques used in creating a HACCP plan are shared with other types of plans, such as food quality and food defense plans. Determining what is critical to monitor, monitoring those parameters in real time, responding when a deviation occurs, and documenting each step along the way are the hallmarks of a successful HACCP plan.

Early in my career as Quality Assurance Manager at Gossner Foods Inc., I took a HACCP workshop presented by Northwest Food Processors Association, McDonald's Corporation, Campbell Soup Company, and National Food Lab Inc. My main takeaway from the workshop was that there was an abundance of opinions about HACCP (this was in 1994), particularly regarding how to implement and maintain the system. Gossner Foods already had a HACCP System in place, although it was elaborate and cumbersome to understand and implement. There were no regulatory requirements for dairy HACCP at the time, but many of our customers required that we have a system in place.

The PMO and NCIMS HACCP Dairy Pilot Program

Before continuing, it may be helpful to provide some background on the regulatory system that Gossner Foods falls under. Gossner Foods is considered a Grade "A" dairy plant that must be in compliance with the regulations spelled out in the Grade "A" Pasteurized Milk Ordinance (PMO), a regulatory guidance document published by the U.S. Food and Drug Administration (FDA). The PMO covers sanitary standards from cow to carton. State Regulatory Agencies adopt the PMO (or equivalent regulation) and oversee the inspection and licensing of plants within their states, while FDA Milk Specialists oversee the state agencies to ensure that they are doing their job. The PMO is updated every two years based on proposals submitted to the National Conference on Interstate Milk Shippers (NCIMS), a cooperative program with representatives from state regulatory agencies, the dairy industry, and academia, with FDA serving as advisor. Proposals are reviewed, accepted, rejected, and/or edited, first by an assigned committee and then by assigned councils. The proposals are eventually voted on by representative delegates of all state regulatory agencies. If accepted and concurred by FDA, the proposal is incorporated into the PMO and/or other appropriate related regulatory documents.

In the summer of 1999, our FDA Milk Specialist asked the Gossner Foods management to consider becoming part of the NCIMS HACCP Dairy Pilot Program, which was being developed as a result of an NCIMS proposal. New regulatory programs proposed to the NCIMS may be studied under a pilot program before final consideration. Some questions were raised regarding Gossner Foods' participation in the pilot because the company is an aseptic shelf-stable milk facility and not a traditional Grade "A" plant with pasteurization. The PMO, at that time, regulated aseptic shelf-stable milk in addition to the FDA Low Acid Canned Food group. In the end, the Gossner Foods facility in Utah was selected as one of the pilot plants for the six regulatory regions delineated by FDA. In addition to the dairy plants that agreed to participate, the state regulatory agency where the plants were located (in this case, Utah) also needed to commit.

At the start of the pilot program, both the industry and regulatory personnel involved received multi-day training developed and presented by the NCIMS HACCP Implementation Committee (HIC). The HIC consisted of federal and state regulatory personnel, as well as representatives from industry and academia. Some of the volatility of the ideas associated with HACCP and what I had experienced in earlier trainings had settled, and protocols were becoming more standardized. I felt encouraged and enthusiastic to implement what I had learned from the HIC training.

As Gossner Foods entered the pilot program, our state regulatory representative and the Regional FDA Milk Specialist conducted a review of the HACCP programs that my company had developed thus far. Some differences of opinion were expected, but I remember questioning if we had gone through the same training as regulatory, because the regulators seemed to interpret so differently the things that my colleagues and I thought we understood so well. Working with FDA and our state regulatory agency led to a flurry of escalated learning from preconceived ideas, as well as gaining insight on the PMO from regulatory officials. All parties learned and worked on developing HACCP concepts as they applied to our Utah facility and the NCIMS program. As a result, Gossner Foods became a facility recognized by regulatory as operating under the Voluntary HACCP Dairy Pilot Program in February 2000. Through our combined efforts to better conform to the principles of HACCP, I gained a better understanding of processing and packaging systems and their associated risks.

In these early years of the Dairy HACCP Pilot Program, there were multiple calls with industry and the International Dairy Foods Association (IDFA) as we learned and worked together to refine and implement the regulation. From the efforts of the HIC and the successful Pilot Program, the regulatory requirements were determined for dairy facilities that wished to participate as an "audited" HACCP plant as an optional alternative to being regulated under the traditional PMO "inspection-based" program. A new appendix, Appendix K, HACCP Program, was added to the PMO in 2003 that contained these regulatory requirements. This optional alternative outlined in Appendix K was considered equivalent to the traditional regulatory requirements also outlined in the PMO. Once Appendix K was finalized and included in the PMO, the pilot program ended and Gossner Foods continued in the optional Dairy HACCP Program. Our plant, from top management down, was invested; our state regulatory agency was invested; and we both saw the benefits.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Over time, I began to participate in the HIC and became familiar with all of the committee members. In May 2009 I was asked by the current Chair of the HIC if I would be willing to be Chair because that individual was changing jobs. I agreed, knowing that I could count on the wonderful HIC committee members for help.

FSMA and the PMO

Just over five years later, in 2014, the Grade "A" dairy regulatory agencies (both FDA and state) were deliberating over the best way to incorporate the Food Safety Modernization Act (FSMA) Preventive Controls (PC) Rule within the PMO. Consideration was given to requiring all Grade "A" dairy facilities to implement and comply with the requirements in Appendix K, HACCP Program, as the proposed Preventive Controls Rule aligned well with that of HACCP, with some minor differences. For example, the PC Rule requires other preventive controls that are not necessarily Critical Control Points, but may be addressed under prerequisite programs under HACCP (e.g., sanitation preventive controls). Additional requirements of the PC Rule, such as a required supply chain program and environmental monitoring verification, also would need to be addressed.

As deliberations continued, the sentiment gradually transformed into the thought process that the PMO was and is the food safety plan for Grade "A" dairies and that, with some additions, the PMO would comply with the FSMA PC Rule. The NCIMS Liaison Committee, made up of state regulatory and industry representatives, was tasked by the NCIMS Executive Board to incorporate preventive controls into the PMO. Whereas operating under Appendix K was intended to continue to be an equivalent and optional alternative to traditional compliance to the PMO, the HIC was to stay abreast of the activities of the Liaison Committee. I participated in many conference calls with the Liaison Committee regarding the changes. From those meetings, we were able to incorporate some changes to Appendix K in the PMO and prepare proposals for changes to be submitted and voted on at the 2015 NCIMS Conference. Several proposals submitted by the Liaison Committee and one proposal submitted by the HIC were passed. These changes were incorporated into the 2015 PMO, but while they were designed to align the PMO with the PC Rule, FDA and others felt that they fell short. FDA, state regulatory agencies, and industry representatives eventually came to a consensus that a new appendix was needed to align the PMO with the PC Rule, with Appendix K shadowing those changes.

With the direction clear, the details needed to be developed and incorporated into the PMO and Appendix K. Under the leadership of the Liaison Committee in cooperation with FDA, a proposal was submitted to the 2017 NCIMS for inclusion of a new appendix in the PMO: Appendix T, Preventive Controls for Human Food Requirements for Grade "A" Milk and Milk Products. Further deliberation occurred at the NCIMS Conference's committee and council meetings. The HIC, with years of PMO food safety program experience, was directly involved in the process, with the added intent of ensuring parallel equivalency of Appendix K with the new Appendix T and alignment with the PC Rule. Proposals for both the new Appendix T and amendments to Appendix K were approved at the NCIMS Conference, adopted by FDA, and incorporated into the 2019 PMO. Accolades were formally announced to the Liaison Committee and the HACCP Implementation Committee at the end of the Conference by the Chair of the NCIMS Executive Board. The two committees were thanked for their "Herculean efforts to align these two historic programs into a single, actionable food safety program for Grade 'A' milk and milk products."

Over the years, I have been a witness to the many advantages of the food safety system outlined in the PMO's Appendix K. Having a HACCP program that is regularly reviewed in detail by the state and FDA seems to carry weight with our customers. Also, having an independent, multi-disciplined, diverse committee in the HIC, which focuses on staying ahead of the curve for HACCP, provides dividends for my company.

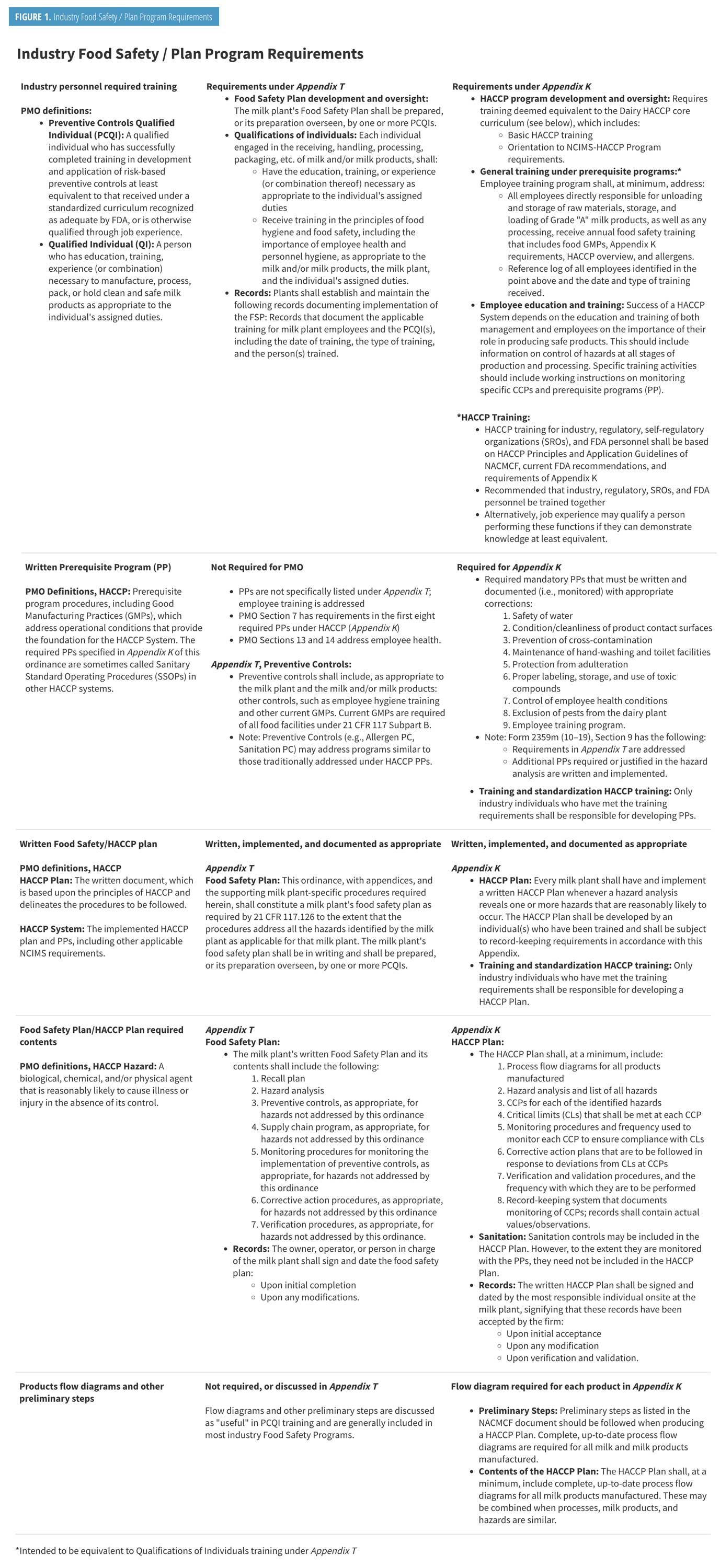

HIC Training Subcommittee Chair Steve Murphy assembled a comparison document between Appendix T and Appendix K in the PMO. It is a multipage document, but I have recreated a portion of it here regarding the Food Safety Plan under Appendix T and under Appendix K of the PMO, to help visualize the food safety plan requirements at a glance (Figure 1).