New X-ray Can Detect Hard-to-Find Contaminants

Credit: Mettler-Toledo

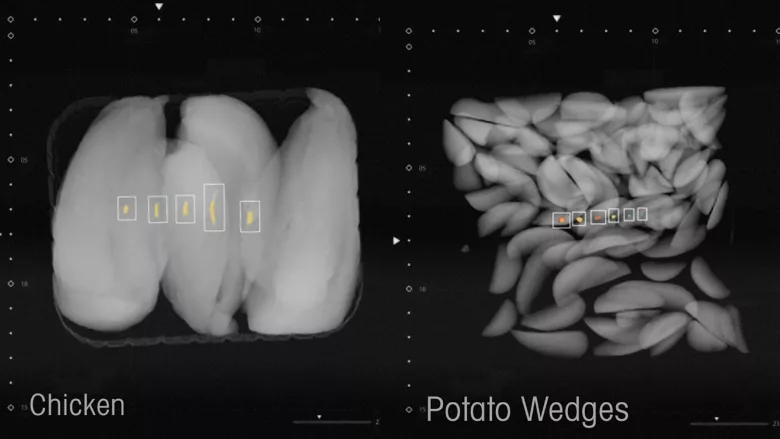

Mettler-Toledo Product Inspection recently launched its most advanced X-ray inspection technology to date, with an enhanced ability to detect low-density contaminants in packaged food products. The new technology will help food manufacturers avoid product recalls, reduce unnecessary product waste costs, enhance product integrity, and protect brand reputations.

Mettler-Toledo’s new DXD and DXD+ dual energy detector technology is optimized for identifying foreign bodies such as calcified bone, low-mineral glass, rubber, and some plastics. Such contaminants are typically hard to detect within ‘cluttered’ or ‘noisy’ X-ray images that are generated by overlapping and multi-textured products such as packs of pasta, chicken breasts, sausages, and frozen potato-based goods.

The DXD and DXD+ detector technology, in conjunction with new Mettler-Toledo Advanced Material Discrimination software tools, helps to separate and remove the food products within an X-ray image, revealing the presence of any lower-density contaminants. As a result of the accuracy and reliability of DXD and DXD+ detection, food manufacturers can be more confident that their products are safe for consumers, and that they will benefit from reduced false reject rates and product waste, helping to deliver a fast return on investment.

The new detector technology is available in two versions, with different levels of dual energy X-ray performance:

- DXD provides high-quality X-ray performance at an affordable price, can operate in the same environments as single-energy solutions, and can be used with line speeds up to 100 meters (m) per minute

- DXD+ provides reliable detector technology for the most challenging applications, collects more data about the products being inspected, features improved image analysis software with clearer images at higher resolutions, and can be used with line speeds up to 45 m per minute.

Mettler-Toledo has demonstrated the reliable performance of its new technology through tests in which a range of different foreign bodies were hidden in 650-gram (g) packages of chicken breasts. The results are as follows:

- Aluminum and low-mineral glass contaminants as small as 2 millimeters (mm) could be detected with 100 percent probability using DXD or DXD+, in comparison to 3 mm with a single-energy X-ray

- Rubber contaminants as small as 5 mm could be detected with 100 percent probability using DXD or DXD+, in comparison to 6 mm with a single-energy X-ray

- For wishbone contaminants, 100 percent could be detected with 100 percent probability using DXD or DXD+, but were undetectable using a single-energy X-ray

- For rib bone contaminants, 95 percent could be detected with 100 percent probability using DXD or DXD+, but were undetectable using a single-energy X-ray

- For fan bone contaminants, 30 percent could be detected with 100 percent probability using DXD or DXD+, but were undetectable using a single-energy X-ray.

Mettler-Toledo also tested its DXD and DXD+ technology for the ability to detect aluminum, low-mineral glass, and rubber in 500-g packages of pasta. The results are as follows:

- Aluminum contaminants as small as 2 mm could be detected with 100 percent probability using DXD or DXD+, in comparison to 5 mm with a single-energy X-ray

- Low-mineral glass contaminants as small as 3 mm could be detected with 100 percent probability using DXD or DXD+, in comparison to 5 mm with a single-energy X-ray

- Rubber contaminants as small as 6 mm could be detected with 100 percent probability using DXD or DXD+, in comparison to 6 mm with a single-energy X-ray.

Mettler-Toledo notes that the test results are dependent on individual applications and are to be referenced for guidance purposes only.

DXD and DXD+ dual energy detectors can now be specified with new purchases of Mettler-Toledo X36 X-ray inspection systems. Little additional operator training is required to use the new technology due to its automatic job set-up, as well as the existing similarities between the Advanced Material Discrimination software and the ContamPlus™ software, which are familiar to existing Mettler-Toledo X-ray users.

Mettler-Toledo is offering personalized consultations to prospective users of its latest technology, either one-on-one at its Lutz facility or virtually. The consultations will include live testing with customers’ actual products, as well as the opportunity to engage with experts in the X-ray inspection field. Mettler-Toledo has also provided a whitepaper with more information on its new technologies, which can be downloaded here.

Mettler-Toledo: www.mt.com

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

.webp?t=1721343192)