Automation Series

Automated temperature monitoring and control ensure food safety

Automated temperature monitoring and control help ensure food safety during transit, processing and storage, and satisfy electronic recordkeeping requirements.

Endress+Hauser’s TM411 thin-film-based RTD sensor provides the response time of a T/C, allowing tighter control of processes. Source: Endress+Hauser.

Emerson’s Rosemount X-well clamp-mount temperature transmitter installs on pipes, allowing temperature measurements without penetration of the pipes. The transmitter is available with WirelessHART and other industry-standard protocols. Source: Emerson.

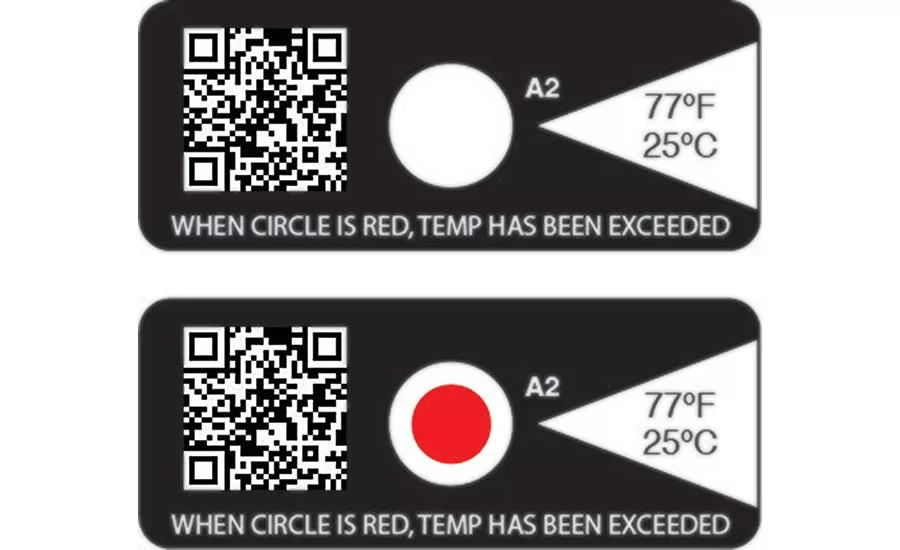

American Thermal Instruments offers ascending and descending chemical indicators that display a color change if a certain temperature has been reached. This can provide a quick go/no-go decision, while data loggers can provide detailed reporting of what transpired for the goods in transit. Source: American Thermal Instruments.

TEGAM’s 932A data collection thermometer collects temperature data and connects via Bluetooth to Android and Apple mobile devices for real-time temperature monitoring and remote instrument control and storage of data to the cloud. The instrument is designed to withstand washdowns. Source: TEGAM.

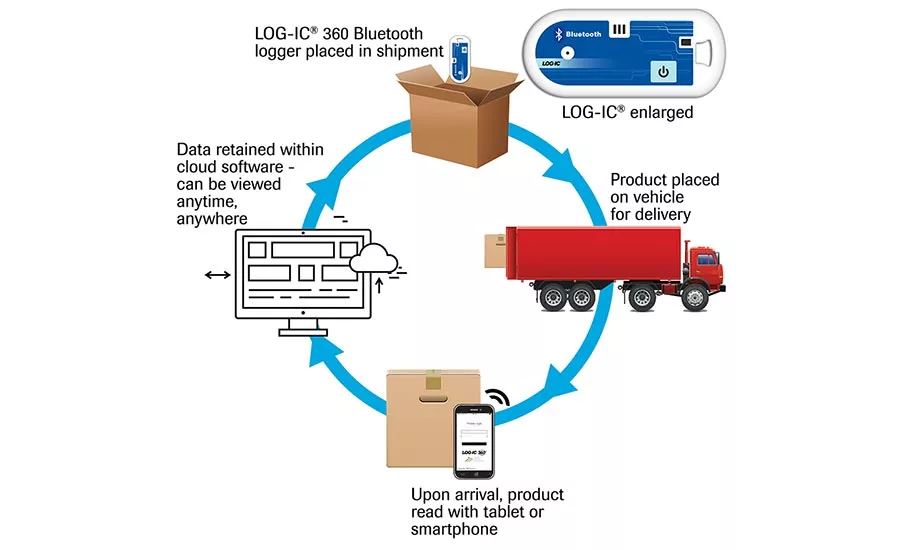

American Thermal Instruments LOG-IC 360 data loggers record data and provide immediate access to temperature records via a tablet or smartphone. Data can be retained in cloud software for viewing at any time. Source: American Thermal Instruments.

Omega’s UWBT Series wireless transmitter turns a smartphone into a portable data acquisition system. The wireless Bluetooth T/C, RTD and humidity meter measures sensor inputs and transmits to a smartphone for further processing, storage and uploading to networks.

Released in March, Fluke’s Model 3550 FC thermal imaging sensor mounts with brackets, is moveable and sends sequential thermal images to cloud-based software for real-time viewing. Source: Fluke.

Of the major measured process variables, temperature is perhaps the most important in food and beverage. Temperature is not only a key variable in a drying or fermentation process, but often a critical kill step required to make your food or beverage safe to consume.

And if you don’t have the records to satisfy regulatory requirements proving critical temperatures were met in every phase of your operation—from farm to plant to warehouse to retail store—your process isn’t likely under control, and you could be in serious trouble.

Article Index:

- The basics don’t change much

- Environmental issues always a concern

- Wireless, handheld, cloud

- Handheld devices: Options abound

- Temperature monitoring during transit

- Meat: Is it done? (Sidebar)

Thanks to today’s technology, it’s not necessary to record temperatures manually on clipboards or even to use a decades-old chart recorder. With modern digital data-logging equipment providing time and date stamps, temperature data points—along with all other process parameters—can be logged and stored, meeting 21 CFR Part 11 requirements for electronic recordkeeping, which satisfies FDA, USDA and other regulatory agencies.

If you really fancy a chart recorder, many models today feature digital outputs and data-logging capabilities. More than just meeting FDA or USDA HARPC/HACCP requirements, today’s technology helps senior management get a handle on temperature status—faster than ever before.

As an example, Monnit, a supplier of remote temperature monitoring systems, helped Hershey’s Ice Cream move several of its old cooler temperature tracking systems (tactographical charting, where a pen scribes a line on a round chart) over to a wireless temperature tracking and monitoring system. Hershey’s previous process involved mailing the charts to headquarters, where they were reviewed and stored (physically). Senior management had no way of being alerted of issues, and the main office had a several-day delay in getting information. Now, the company has instant access to temperature data from anywhere, and alerts are sent immediately if there is an issue. The processor also maintains all of its data digitally, so it’s no longer necessary to physically store paper charts.

There’s more flexibility with temperature instrumentation today—whether it’s a fixed-location sensor or convenient handheld devices that offer internal storage or wirelessly connect to external storage, either on premises or in the cloud. Even fixed-location sensors can be connected wirelessly for locations where wiring is not practical or too costly. Speaking of sensors, both direct contact and non-contact temperature devices offer solutions to difficult problems and can be used together for improving temperature control in applications where internal product temperatures are more critical than external surfaces.

The basics don’t change much

“Sensing elements themselves are pretty stable in that they don’t tend to change,” says Paul Gobeille, Stellar senior automation engineer.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

For example, you’ll find that the theories behind thermocouples (T/Cs), RTDs (resistance temperature detectors), thermistors and infrared (IR) sensors presented in various sources are virtually the same as when they first appeared. So, while temperature sensing technologies don’t change, there are other challenges and many new developments in sensors.

For example, a recent food temperature measurement probe application required exposure to 250°F media and had to be NFS certifiable, be waterproof to 24 inches immersion in water and consist of non-metallic construction at the point of food contact, says Ron Desmarais, engineering manager for Omega Engineering.

“In this case, we selected PET plastic for the body of the sensor that is in direct contact with the food surface and 316L SS in other areas where metallic materials were allowed,” he explains. “Selecting materials to work in the temperature ranges and in contact with various solid, liquid and gaseous environments is a key consideration in the material selection and design of any new product.”

For those who would like to use RTDs but haven’t because RTD response times have been inherently slow, Endress+Hauser has come up with a thin-film RTD (TM411) that has the response time of a T/C, says Keith Riley, national product manager, pressure & temperature products.

“Traditional RTDs in a 9-mm thermowell have a t90 response time [the time needed for 90 percent of the process step change to be reflected in the output signal] of approximately 20 to 45 seconds depending upon the technology [wire wound/thin film] and geometry [straight/reduced/tapered] utilized. Endress+Hauser’s QuickSens RTDs can reduce the t90 performance of a probe in a 9-mm thermowell to approximately five to 20 seconds depending upon the geometry. This provides end users with the stability and accuracy of a typical RTD measurement and speed of response of a T/C,” says Riley.

Indirect IR thermometry is fast—typically on the order of milliseconds, according to Ircon’s (now part of Fluke Process Instrumentation) online Noncontact Infrared Temperature Measurement guide. There are certain applications that lend themselves to this technology, according to Ircon. For example:

- Checking the temperature of food exiting a flash cooler

- Measuring the temperature of cereals at the exit of puffers and flakers

- Checking the temperature of soup as it’s cooked in large vats—as well as liquids and vegetables in plastic or glass containers

- Measuring the temperature of products inside ovens and roasters.

While indirect IR thermometry can measure the external temperature of meats in an oven or roaster, determining the internal temperature of the meat is another story. In terms of knowing what the internal temperature is, you’d have to make some assumptions (e.g., based on the mass of a hamburger patty, internal moisture, geometry, etc.) to infer an internal temperature from the surface temperature. (See sidebar “Is it done?” for details.)

When it comes down to food measurements, it appears that contact thermometry is the preferred method to measure internal temperatures as an indicator of doneness.

“We have been working on such a product with a food cooking OEM where the interior of a food product needs to be measured,” says Omega’s Desmarais. “Contact sensors, whether they are RTDs or T/Cs, are typically used in these applications. The sensors can be customized with small diameters, pointed ends and other features that help to make the measurement as easy to do as possible.”

Speaking of speeding up temperature measurements, unfortunately, one necessary maintenance step slows down overall production time—and that’s sensor calibration. Endress+Hauser’s Riley describes a new quick-connection technology called QuickNeck, which is said to reduce calibration cycle times by an average of 15-20 minutes per temperature sensor. QuickNeck and a mobile calibration rig eliminate the need to disconnect a transmitter from the control system during metrology cycles. Besides speeding the calibration process, this system eliminates the possibility of human error due to disconnecting and reconnecting wiring.

One way to decrease unnecessary maintenance, which can slow production, is through the use of sensor diagnostics.

“We have transmitter diagnostics that can help predict when a sensor is near failure,” says Caitlin Bissell, Emerson Automation Solutions temperature product manager. “These include T/C degradation, open/short sensor diagnostics and sensor drift alert.”

For clarification, T/C degradation provides continual evaluation of T/C loop status and can issue a warning before sensor failure. The open/short sensor diagnostic alerts users to the most common type of sensor failure. And finally, the sensor drift alert detects the condition of degrading sensors on a transmitter installed with dual sensors and can alert the user of the status of the degrading sensor.

Environmental issues always a concern

There are still a number of mechanical temperature instruments that are used in food processing and the brewing industry, says G. Alan Clark, engineering support, inside & outside sales, Palmer/Wahl Instrumentation Group. Newer and updated instruments are moving away from containing mercury. Now, there are FDA- and USDA-approved electronic units that can be used in place of older mercury-based instruments.

Many food processing environments place environmental demands on electronics. For example, most printed circuit boards are only stable up to 120°F, whereas military-grade boards are good up to about 160°F-170°F. Other issues are water and steam, the latter of which often leaks from pressurized sources, thus, equipment needs to be well sealed and 316 SS is recommended.

“In my experience, the most challenging environments are in washdown areas,” adds Stellar’s Gobeille. “Sensors in these areas are hit with high-pressure, high-temperature water and solvents used in the cleaning process. We see more failures with these devices from corrosion and aggressive heat and water than in any other application. [Using] quality parts from qualified vendors is the best way to combat this challenge in the long term—this is certainly not an area to cut corners.”

Washdowns aren’t the only threat to sensors and probes.

“The biggest challenge is longevity with immersion sensors,” says Emerson’s Bissell. “They tend to fail quickly due to vibration and can have a reduced lifespan under temperature extremes. We provide Rosemount X-well technology that allows accurate process temperature using a surface sensor to eliminate process intrusion.”

X-well is a pipe-clamp, surface-mount technology that can be installed with a standard pipe clamp procedure and ordinary hand tools.

Resistance to vibration is also a challenge to RTDs, but it can be overcome with design.

“StrongSens is a thin-film RTD with nearly 20 times the vibration resistance of standard wire wound or thin film [devices],” says Endress+Hauser’s Riley.

A typical RTD has a vibration resistance up to 3 g; Riley says StrongSens has been designed to withstand vibration in excess of 60 g. As Bissell suggested, surface mounting is another option for installing a temperature sensor. It allows the use of more traditional materials of construction in highly corrosive or abrasive applications.

While response times will be longer, surface mounting is well suited for applications that run at a relatively consistent temperature for long periods of time. Best yet, the sensor/thermowell is kept out of the process, so there is no difficult-to-clean collection point for potential buildup of bacteria.

Any equipment used in food processing applications must be designed to be cleanable and not have spaces that can harbor bacteria, and this applies to handheld equipment as well as fixed sensors. TEGAM designed the 931A and 932A data thermometers to meet these challenges.

“The case and displays were designed to minimize seams and crevices, and the keyboard is fully sealed,” says Greg Tolentino, product manager. “These features make the instrument less likely to accumulate debris during use and easy to wash down.”

As a moveable, fixed-mount temperature sensor, Fluke’s 3530 FC K-type temperature sensor is intended for condition monitoring applications. Fitted with a Type K T/C, the unit works up to 800 hours on four AA batteries and communicates wirelessly (up to 20 m) on the 2.4 GHz ISM band. The company has also launched its 3550 FC thermal imaging sensor, which according to Global Content Manager Leah Friberg, is also moveable, bracket mounted and line powered. The device can send its sequential thermal images to the cloud for real-time viewing.

Wireless, handheld, cloud

If you have an older facility without available wiring for process control networking and sensors, wireless may be a workable option.

“Wireless networks can most certainly be more cost effective [than running wires], but it all depends on distances,” says Stellar’s Gobeille. “If it costs more to have an electrician run all the wiring than to invest in a wireless system, then wireless is a no-brainer. When it comes to retrofit process applications, wireless is especially beneficial for large distribution areas.”

If a processor has a significant volume of space that needs to be cooled—e.g., a large storage room or freezer—it would have been previously limited to one or two wired temperature sensors. However, today’s wireless systems can now allow for four to six sensors in these bigger spaces, which increases accuracy and reduces install cost tremendously, adds Gobeille.

“Wireless systems can be a very useful tool to a facility,” says Endress+Hauser’s Riley. “Normally, the application or site-specific conditions will play a major factor in determining if a wireless solution provides a better installation than a traditional hardwired approach.”

However, you must consider if your plant, especially if it’s older, has many obstructions, which can block or interfere with wireless transmission.

“You need to keep in mind that equipment with strong electromagnetic fields or pulses that might disrupt transmission might be present,” says Palmer/Wahl’s Clark.

Also, personnel roaming about the plant with powerful two-way radios could temporarily interfere with wireless sensor transmissions when they transmit close to wireless sensor equipment, adds Clark.

“With RF [radio frequency] and the metal structure of coolers, tanks, ovens, etc., we find that it is best to mount the electronic portion of the sensor on the outside of the appliance and insert a leaded probe to track the internal temperatures,” says Matt Moulton, Monnit marketing director. “In cooler or freezer applications, we also recommend using a temperature buffer on the probe itself to prevent false readings that can be caused by the momentary influx of outside air when a cooler or freezer door is opened.”

One solution to the problem of interference or long paths is to employ a mesh network, which is composed of a wireless gateway and sensors that create a self-organizing network. WirelessHART is one protocol that major sensor/transmitter manufacturers like Endress+Hauser and Emerson support. Mesh networks can work around interference, physical barriers and long distances.

Where mains power is not available, most wireless sensors work well on batteries. Endress+Hauser temperature transmitters can be used in conjunction with the SWA70 WirelessHART adapter to provide wireless transmission of sensor measurements. The SWA70 is a lithium battery-powered device that accepts and transmits the output from one to four separate temperature transmitters, says Riley. Not only that, the WirelessHART protocols allow communication with other vendor-supplied temperature sensor/transmitters.

If a power infrastructure is already in place, the Rosemount 848T wireless temperature transmitter can be used to obtain up to eight temperature measurements in close proximity to each other, says Emerson’s Bissell. In a remote location running on batteries, the 848T accepts up to four independently configurable inputs. If there is a lack of I/O space to add more devices, simply add a wireless network to install more points, says Bissell.

Handheld devices: Options abound

Traditionally, a worker had to make the rounds, either reading thermometers or chart recorders in cold rooms or taking the temperature of products or the environment with a handheld thermometer. That person then had to record the measurements in a log or enter them into a spreadsheet, leaving plenty of opportunity for errors.

This is not necessary anymore. Handheld temperature devices range from leave-behind loggers to traditional IR thermometers and high-accuracy logging thermometers with contact probes—not to mention temperature calibrators, says Fluke’s Friberg.

Handhelds today can measure direct temperatures through RTD or T/C inputs, and some have the added capability to measure indirect (surface) temperatures through an incorporated IR thermometer—or maybe an imaging IR system. In most cases, handheld devices will:

- At least store readings internally for USB upload at a later point to a computer, or

- Have Wi-Fi interfaces to upload directly to a plant-wide network or

- Work in tandem with a user’s smartphone or tablet using Bluetooth to process data and upload to a local network or even a cloud-based system.

“As everyone is aware, handhelds are a must today,” says Randy Lane, American Thermal Instruments chief strategy officer. “The biggest advancement that we have developed is to utilize our customers’ existing infrastructure to handle the cold chain. Our electronic loggers communicate through NFC [near field communication] or Bluetooth 4 and can easily manage data anywhere, anytime.”

Lane says it’s much easier and more accurate to pull the data straight from the loggers rather than physically handling written records. Plus, it’s more efficient to manage and share the data over the cloud.

“TEGAM’s handheld thermometers, when used with the TEGAM Thermometer Link and TEGAM Cloud, provide a date/time stamp for every saved temperature measurement and are tied to a user-definable location identifier (i.e., a lot, batch, pallet, purchase order number, etc.),” says Tolentino.

This replaces the clipboard and pencil with a more efficient, accurate and instantaneous way to deliver actionable information to quality and management personnel. The Models 931A and 932A both feature Bluetooth wireless connections and connect with several T/C types.

Omega Engineering features a similar device, the UWBT Series wireless transmitter for smartphones and tablets. Connecting via Bluetooth, the device handles T/C, RTD, pH and humidity sensors, and can log up to 10 samples per second, turning tablets and smartphones into data-logging and monitoring devices, which then can move the collected information just about anywhere via email or the cloud.

Temperature monitoring during transit

Temperature monitoring isn’t finished when your product leaves your plant or warehouse on its way to its next stop. Various data-logging approaches have been taken, from fixed devices inside trailers to portable units and even non-electronic, thermal-indicating temperature strips. American Thermal’s Lane says the need for electronic data loggers has gone up, thanks to FSMA’s new rules and regulations regarding transporting human and animal food.

“The goal of these new rules is to ensure that transportation practices reduce safety risks by leveraging sanitary transportation, including temperature control,” he says. “What this means for food deliveries is that the shipper and carrier must agree to a temperature monitoring device for shipments of foods that require temperature control for safety.”

Electronic data loggers provide an easy method to collect temperature data during a shipment and determine if any temperature excursions happened during transit that could affect the quality or food safety of a shipment, adds Lane.

“Portable temperature loggers are used to spot check refrigerated truck fleets, rotating the devices between vehicles to assess quality of temperature controls,” says Fluke’s Friberg. “Streaming temperature sensors require a cellular or Wi-Fi connection, which isn’t always available, but drivers can use the system locally and set alarms on their smart device, should temperature conditions dip below [or rise above] thresholds.”

“Monnit is being used by several companies to track temperatures, from manufacturing all the way to delivery,” says Moulton. “Monnit’s cellular gateways allow for temperature tracking in trailers at loading docks and during transit. We recommend using a few temperature sensors at various locations in the trailer to ensure safe temperatures in the entire trailer.”

Finally, chemical temperature indicators can provide a cost-effective, easy way to track if a temperature breach has occurred during product shipment.

“We find that customers need an ascending threshold chemical monitoring indicator to track if something is reaching an excessive temperature, and others require descending threshold chemical indicators to track if something has reached an unacceptably low temperature,” says Lane.

Some processors want a dual monitoring solution that indicates whether a product has been too hot or too cold in shipment. Temperature thresholds are set by users and are recognized by a color change on the label.

Meat: Is it done?

To check the internal temperature of something like a hamburger cooking in the pan, a conventional thermometer probe must now be entered into the cooking meat. Georgia Tech Research Institute (GRTI) has been looking for a solution to make it easier for processors to get a handle on the doneness of their products using indirect IR temperature sensors.

“Food safety is a critical issue, so producers often compensate for natural variability in the product and variability in the measurement by overcooking products,” says John Stewart, GTRI senior research engineer. “But overcooking wastes energy, degrades product quality, lowers the maximum throughput rate of the production line and decreases product yield.”

At typical production rates of 6,000 lbs./hr., the losses from overcooking can have a significant financial impact on producers. To minimize undercooking and overcooking, Stewart and his associates built a system that measures the three-dimensional shape and surface temperature of every piece of meat before it enters the oven.

After meat products travel through an oven for cooking, technicians randomly test samples with T/C insertion probes to ensure the product reached minimum cooking temperature.

“We’re focusing on analyzing the product before it goes into the oven because at that stage, there is still time to make changes in the cooking time or temperature to ensure that all pieces get cooked adequately,” says Stewart. “Once the product comes out of the oven, it’s too late to correct any undercooking.”

The system consists of two cameras: a wide-area 3-D camera and an IR camera—mounted above a 48-inch wide conveyor belt. By measuring the 3-D profile of the meat, the screening system can identify individual products and detect arrangement issues such as overlapping product.

Sounds easy? Locating individual pieces of meat on the belt placed close together is a challenge, and thermal IR cameras sometimes view the product and belt temperatures as nearly the same, which provides very little contrast. Height information offers better contrast between pieces of meat, but sometimes, further image processing is still required to determine the boundaries between individual products if they’re close together or touching.

Once individual product shapes have been measured, they are compared with a library of previously recorded cooking results for meat products with a similar shape and cook profile that matches the current oven cook profile. Thermal heat and mass transfer models, along with the current cook oven profile, are used to determine whether a particular product will reach the desired end-point temperature.

“The system predicts the percentage of product that will be overcooked and identifies individual pieces of meat or arrangements of products that are likely to undercook,” says Stewart. “In the future, a producer might use this information to fine-tune the product arrangement before it reaches the oven.”

The 3-D profiling system and models have been tested using chicken breast filets, and the researchers plan to test the system in a local plant.

For more information:

Paul Gobeille, Stellar, 904-260-2900,

pgobeille@stellar.net, www.stellar.net

Matt Moulton, Monnit, 801-561-5555,

mattm@monnit.com, www.monnit.com

Ron Desmarais, Omega Engineering, 888-826-6342,

rdesmarais@omega.com, www.omega.com/temperature

Greg Tolentino, TEGAM, Inc., 800-666-1010,

gtolentino@tegam.com, www.tegam.com

Leah Friberg, Fluke Corporation, 844-427-2269,

leah.friberg@fluke.com, connect.fluke.com

Keith Riley, Endress+Hauser Inc., 888-363-7377,

keith.riley@us.endress.com, www.us.endress.com

G. Alan Clark, Palmer/Wahl Instrumentation Group, 800-421-2853,

agclark@palmerwahl.com, www.palmerwahl.com

Caitlin Bissell, Emerson/Automation Solutions, 800-999-9307,

Caitlin.bissell@emerson.com, http://tinyurl.com/kt8fl7b

Randy Lane, American Thermal Instruments, 800-648-6339,

info@americanthermal.com, www.americanthermal.com

This article was originally posted on www.foodengineeringmag.com.

.webp?t=1721343192)