Software helps processors stay in compliance with FSMA

As FSMA makes it more vital, companies that embrace food safety software will see the most benefits from it

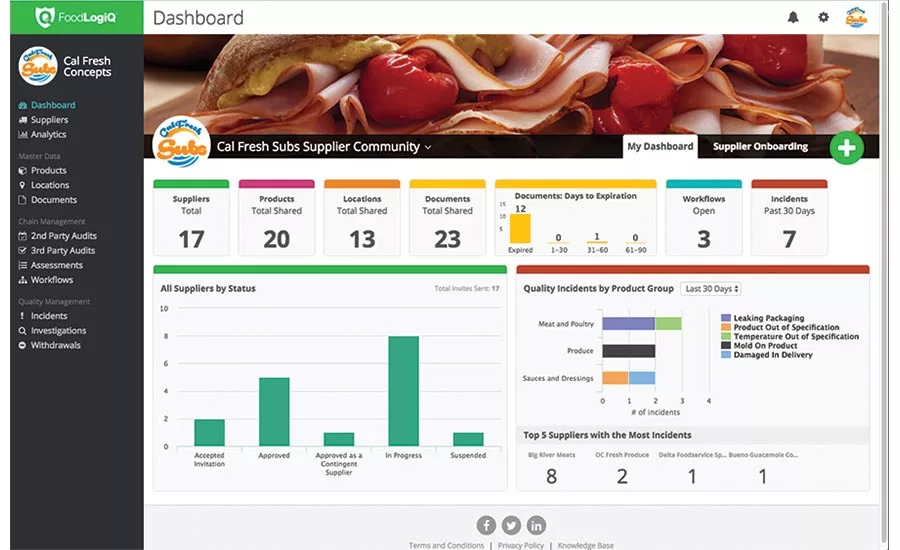

Screenshots of FoodLogiQ show how users can transform data into information that helps them better manage the plant floor and the overall supply chain. Source: FoodLogiQ.

METER Group offers the Skala system, which reduces the time it takes the quality manager to manage, review and approve records, because readings for all instruments are in one place and error-free. Source: METER Group.

METER Group’s Skala system can save labs a day’s worth of time every week. It’s the first data management system purpose built for food quality assurance labs. And it has been shown to save a midsized lab (one that makes 100 readings/day) more than 550 lab tech and quality manager hours every year—more than one workday a week. Source: METER Group.

When it comes to food safety, there are lots of reasons for companies to be vigilant with their data, such as international regulations, the Food Safety Modernization Act, the expense of a recall and even social media, because if someone gets sick eating your product, the first place they will probably go to is Facebook, followed quickly by Twitter.

At least that’s how Doug Fair, COO, InfinityQS International, Inc., a provider of statistical process control software and services to manufacturers, sees it.

Article Index:

- Why food safety software?

- What to look for in food safety software

- Sidebar: Four software characteristics

“As food and beverage supply chains become increasingly global, manufacturers are faced with greater challenges to maintain the quality and safety of their products,” he explains. “Consumers demand better products and will quickly opt for another brand or voice their grievances through social media if they’re not satisfied. Governments are increasing regulations to maintain traceability from farm to fork and boat to plate, especially when that path is international. And in the past five years, recalls have increased fourfold, averaging $10 million in total costs per recall.”

Combating these challenges means quality managers need real-time data “from within individual plants, across the enterprise and into the supply chain,” Fair says. “Only then, will they be able to identify opportunities to improve product consistency and quality control, minimizing, or even eliminating, the risk of defects and recalls and, therefore, reducing the associated costs.”

Dean Wiltse, CEO of FoodLogiQ, a provider of supplier management and traceability software as a service (SaaS) technology, says the food and beverage industry is indeed undergoing a transformation at all levels.

“This new direction is a result of many factors, including the public’s demand for transparency around what goes into their food and where it comes from, increased regulations in light of the Food Safety Modernization Act and the staggering number of high-profile contaminations and recalls in recent months,” Wiltse says. “This has led to a host of new challenges facing an increasingly complex global food supply chain.”

And that’s where good food safety software comes into play.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Why food safety software?

Scott Campbell, CEO of METER Group, worked in healthcare IT before METER Group, and he says the food industry seems to be where the healthcare industry was 20 years ago when it comes to software and data.

“Initially, companies thought, ‘We’re going to put computers in [hospitals] and solve everyone’s problems,’” he explains.

Obviously, they quickly realized it was more complicated than that, because having data and being able to use it are two different things.

And now that the food industry is facing new restrictions as part of FSMA, it’s being forced to look at food safety data collection and their methods, with many opting for software. Of course, it’s all about perspective, and companies can choose how they look at it.

“FSMA, broadly speaking, is just going to require people to collect a lot more data about their product and to prove that food companies are doing what they always said they were doing, but the regulatory requirements become much more stringent,” Campbell explains. “Companies really have a choice at this point, which is just to try to do a bare minimum that would get them through a third-party audit or to look at FSMA as an opportunity to take all this data and use it to improve the profitability and product quality of their operations.”

Collecting food safety data and sticking it into three-ring binders doesn’t do much good, especially if there is a food safety incident, whereas software can free up valuable time for the quality control department. For instance, METER Group offers the Skala system, which reduces the time it takes the quality manager to manage, review and approve records, because readings for all instruments are in one place and error-free.

The company claims the system can even offer labs an extra day’s worth of time every week. It’s the first data management system purpose-built for food quality assurance labs. And it has been shown to save a mid-sized lab (one that makes 100 readings/day) more than 550 lab tech and quality manager hours every year—more than one workday a week.

Campbell says companies can be slow to embrace it, not valuing the saved time since they believe they will still require the same number of technicians. But there are lots of things companies can do with that free time.

“Most people say, ‘I wish I could get [the quality team] out to the floor more often, so they could prevent problems,’” he says. “The exciting thing that we see is the potential for that quality function within a company. All food companies are trying to be profitable, make a high-quality product and a safe product. What we have found with quality over the years is that it’s been pigeonholed into this idea of 'the people who say no.’ And Skala is a way for quality managers to flip that script.”

QA can use the data from Skala to partner with other teams to continuously improve products.

“Now, they can share with other people in other departments and say, ‘Hey, here’s the product that we have the biggest problem with. Let’s work together to fix it,’” Campbell says.

For example, if the data is showing that one out of every 20 batches of the product has to be scrapped, and the company loses $10,000 on each scrapped batch, they can work to create a system where only one out of 50 or one out of 100 has to be scrapped. And those savings in turn mean the quality department is actually helping with profitability.

InfinityQS’s Fair agrees that seeing food safety software from only a quality control perspective is shortsighted.

“Quality has always been viewed as a problem on the plant floor. But at InfinityQS, we challenge manufacturers to instead re-imagine quality as a competitive advantage. The same quality data that identifies the problems on the plant floor is an untapped source of insight to drive strategic transformation across their entire enterprise,” he explains, adding that when looking at which food safety software to choose, manufacturers should consult all stakeholders, including the C-suite.

“While many manufacturers believe food safety and quality is a function on the plant floor, it is the few that understand the hidden potential of the resulting data that will include all stakeholders in the decision-making process,” he says. “This is particularly important for multi-plant deployments, so systems can be mandated from the top and standardized across operations.”

Khalil Divan is the senior director, food and beverage vertical market with Thermo Fisher Scientific, which includes the brands Thermo Scientific, Applied Biosystems, Invitrogen, Fisher Scientific and Unity Lab Services, providing enterprise-level informatics solutions.

Divan says food safety software protects against recalls, which companies should not overlook.

“Since regulations are only increasing, having defensible and traceable data at hand for regulators or auditors is essential and could mean the difference between a minor batch recall or a wholesale recall of product, which would ultimately cost more to the company than lost revenue. A wholesale product recall could impact the company’s brand equity and shareholder confidence,” Divan explains.

Divan points to some recent, “very public examples,” including contaminated peanuts resulting from lack of HACCP adherence and an ice cream recall due to the lack of sample data captured in a quality control process.

“These are just a few [incidents] where the financial impact was far more than the cost of implementing a proper data management system,” Divan says. “Lost in the discussion of what standards should be is how to measure them, track them inside and outside of an enterprise and respond as quickly as possible if a breach of any kind occurs.”

Divan says food safety software is actually prudent business insurance.

“Simply put, you are only as strong as your weakest link. If food safety is a chain, rather than a confederacy of monoliths, then weak links will stand out as the liabilities they are,” Divan says. “A misstep by a single supplier can affect a brand’s market cap significantly, and that single supplier is one recall away from bankruptcy.”

What to look for in food safety software

When companies decide to make the leap into food safety software or to upgrade their existing system, there’s a lot of things to consider.

Campbell says the most important thing companies should look for when considering food safety software is ease of use.

“First and foremost, companies should look for simplicity,” he says. “It’s such a cliché to say that you need software that’s easy to use, but it gets lost so often in the actual software that I see people selling in the industry. It has to be easy to use.”

Wiltse agrees, adding that customer support is part of ease of use.

“If it is hard to use, adoption will be low, and companies will not get the value and ROI,” he explains.

And management should make sure it actually makes people’s jobs better.

“So, for example, one of the key pieces of Skala is we connect it directly to analytic devices—anything in the lab that has a serial port—and because we’re doing that and because we’ve automated the workflow of collecting a reading in the lab, every time the system is used, it saves the user two minutes of time,” Campbell says.

And if a user needs a moisture reading, all he or she has to do is touch a screen to get it.

“The system already knows all about your product, so you just touch on the screen saying, ‘This is what I want to read,’” he says. “And as soon you do that, you’re finished, so you don’t have to babysit instruments, you don’t have to write down readings, you don’t have to check readings, the system does all of that for you. That’s a really key feature that people should look for. Does it save my technicians time; does it save me time?”

Another thing companies should look for is what Campbell calls the logic feature, where the software can actually react to the data it is collecting. So, for example, it knows that if it gets a reading that is out of range, it should automatically take three more readings, and if those readings also come back out of range, then that batch should automatically be pulled.

And that’s exactly the kind of thing companies have to show they do now under FSMA.

“If the system can be set up to support those workflows, it also automates the documentation tasks associated with those workflows,” Campbell says. “Then, when your auditor comes in and says, ‘Prove to me that the batches that don’t pass spec are put on hold,’ you show them the automatic data.”

And, of course, he says, the system should be paying for itself within as little as a month.

“A lot of people see these systems as huge investments, but … if it [a system] is avoiding transcription errors, it should [pay for itself] right away,” Campbell says.

With FSMA, there are also things specific to the regulation that companies should be looking for.

Wiltse says that because FoodLogiQ was developed by food industry experts specifically for the food industry, the company understands what its customers are facing with FSMA and what they need to be compliant.

“For instance, the platform serves as a central repository for food safety documentation, so our customers can compile critical required records and respond to FDA requests for documentation quickly,” he explains.

The Foreign Supplier Verification Program (FSVP) is another critical component of FSMA that food safety software can help with.

“It requires food companies to verify and document the ‘hazards’ that they are relying on their foreign suppliers to control,” Wiltse says. “Supplier management can also be time consuming, so we enable our customers [with] the ability to streamline communication workflows and access a supplier performance dashboard for real-time visibility into expiring documentations and scorecarding who has the most quality incidents.”

He says many food companies have relied on a more linear approach to supply chain transparency and traceability. But simply knowing where a product has come from one step back in your supply chain and where it is being sent or sold one step forward is no longer adequate.

“With increasingly complex supply chains, enhanced traceability across your entire supply chain is critical for effective recall management and managing quality of your products,” he explains.

And for high-risk foods, such as dairy or products that spoil easily, it is especially critical to have visibility into the “last mile” of that product’s journey in the supply chain before reaching the consumer.

“To give consumers the transparency they want, it is imperative that a company implement whole chain traceability, rather than relying solely on the movement of product within its own four walls,” Wiltse says. “This not only satisfies FSMA rulings, it also just makes good business sense.”

For its part, FoodLogiQ allows companies to share and track critical product movement across their extended supply chains.

“You can also aggregate tracking events at the lot level into a complete visualization of the supply chain,” Wiltse says. “With FSMA now in effect, the FDA has mandatory recall authority for all food products, along with more flexible standards for detaining products that are potentially in violation of the law—including the ability to halt operations of a facility that is under suspension. With FoodLogiQ, you can retrieve records instantly and know where your products are at all times in the supply chain.”

Fair says moving into food safety software is basically inevitable for food and beverage companies these days.

“Manufacturers spend enormous amounts of time and energy collecting and responding to an avalanche of quality-related data that ends up in disparate spreadsheets, physical filing cabinets or siloed in databases or file servers across the organization,” he says. “But when data is scattered and non-standardized, it’s impossible to visualize and analyze what’s happening—in real time or over time.

“Instead, manufacturers must unify, standardize and aggregate that quality data to create visibility into production sites across the entire enterprise—including suppliers, incoming inspection, raw materials, in-process checks from shop floor operators and the quality lab, process data, packaging and finished products,” Fair continues. “The aggregated data generates actionable insight about the enterprise’s processes, suppliers and manufacturing operations. These insights can be applied across the enterprise to streamline, optimize and transform processes and operations, elevating product quality, improving efficiency, impressing customers and creating exponential cost savings.”

And of course, in the end, it all goes back to the bottom line.

“When manufacturers shift their thinking about quality from ‘How can I fix this?’ to ‘How can I use this to my advantage?,’ they’re already ahead of the competition,” he explains. “They no longer think just about what they reacted to yesterday, but instead, about what they can proactively do tomorrow or next year. This turns today’s quality data into tomorrow’s strategic operational decisions to drive real, measurable benefits to the bottom line.”

Four software characteristics

Doug Fair, COO, InfinityQS International, Inc., offers his list of essential functions food safety software systems should provide processors.

- Lot Genealogy and Traceability: Tracking raw materials and ingredient lot codes throughout operations with genealogical “trees” and a complete view of the incoming/outgoing product relationship can determine information critical for responding to product recalls. Examples of these relationships include identifying which materials were used in the production of a specific finished lot, what finished lot was created from which incoming lot and where incoming raw ingredients were consumed. Food safety software with a strong analytical engine can also determine root causes for nonconforming lots.

- HACCP, SSOP and Audit Assistance: Responding to audits and ensuring compliance with Hazard Analysis and Critical Control Points (HACCP) and Sanitation Standard Operating Procedures (SSOP) can be horribly time consuming. Food safety software should offer workflows and visual checklists to automatically prompt operators for critical quality checks.

- Database Audits: To ensure traceability, it’s imperative to know every modification, edit or change to any database record. Make sure that the software has processes in place to not only track the changes, but also include specific reasons for the changes and space to add free-form comments for further clarification.

- Net Content Control: Manufacturers in the food and beverage industry must comply with filling requirements for net content (weight) control. Food safety software should support the U.S. Department of Commerce Maximum Allowable Variation (MAV) and European Union Tolerable Negative Error (TNE) and T1/T2 requirements. Global manufacturers will also benefit from additional net content control reporting options.

For more information:

Doug Fair, InfinityQS International, Inc., 800-772-7978,

www.infinityqs.com

Dean Wiltse, FoodLogiQ, 866-492-4468,

info@foodlogiq.com, www.foodlogiq.com

Khalil Divan, Thermo Fisher Scientific,

khalil.divan@thermofisher.com, www.thermofisher.com

Scott Campbell, METER Group, 509-332-2756,

scott.campbell@metergroup.com, www.metergroup.com

This article was originally posted on www.foodengineeringmag.com.