Ensuring the Safety and Quality of RTE Meals for U.S. Service Members

Many RTE food technologies were created and first commercialized by the U.S. Armed Forces

Ready-to-eat (RTE) foods have been part of the human lexicon for centuries. Whether it is a traveler on a long journey across the Silk Road back in antiquity to trade their goods, a factory worker in the early 20th century who was not allowed to take a break during their 12-hour shift, or a soldier on the battlefield, the ability to find foods that can be consumed quickly and without the need for further safety interventions has been critical to the success of their respective missions.

On a less dramatic scale, as a parent with two young children under the age of five, I am constantly finding myself in situations where the kids' hunger comes on at the most inopportune times (i.e., while rushing to dance practice, which we're already late for). Luckily, a quick stop at a convenience store on the way can provide a wide variety of RTE food options for each of my little ones. In modern society, the concept of immediate gratification has become a tenable expectation for many. A person can think in the morning of an item they need, purchase that item, and receive it on their doorstep within a couple of hours. RTE foods, although not a modern concept, fit in perfectly with the consumer's need for immediate gratification and, therefore, have become staple offerings at many food destinations.

RTE foods have been processed so that they can be safely consumed without the need for further heat treatment and minimal to no further preparation. The variety of RTE foods on the market is so vast that a consumer can find the perfect RTE meal that will meet their budgetary and dietary needs, while also satisfying a particular craving. For consumers, RTE foods are the perfect complement to their hectic daily lives, but did you know that this particular category of food products has also been critical to the success of the U.S. Armed Forces? In fact, many of the technologies adopted by the private sector to develop and manufacture RTE foods were created and first commercialized by the U.S. Armed Forces.

Meals, Ready to Eat ("MREs") are self-contained operational rations that contain an entrée, along with other items such as desserts, snacks, beverages, and a Flameless Ration Heater, packaged into flexible packaging (Figure 1). MREs provide soldiers with the functional nutrition their bodies require to effectively operate when engaged in activities considered to be highly intensive, such as boot camp or when carrying out actual military operations.1 To learn more about MREs, I had the opportunity to visit the U.S. Army Combat Capabilities Development Command (DEVCOM) Soldier Center located at the U.S. Army Natick Soldier Systems Center in Natick, Massachusetts. One of the U.S. DEVCOM Soldier Systems Center's charges is to research and develop various types of MREs for the U.S. Department of Defense (DoD). At the Soldier Center, I was fortunate to speak with two experts: Dr. Genevieve Flock, Research Biologist in the Food Protection and Innovative Packaging Team Combat Feeding Division, and David A. Accetta, Chief of Public Affairs.

FIGURE 1. A Pair of MREs (Credit: Ashley Pomeroy, Wikimedia Commons)

Weight Reduction

The ability to provide nutritional foods that can be consumed efficiently and sustain active military personnel initially began during World War 1 with the trench ration. The trench ration consisted of the basics: hard bread, sugar, salt, meat or bacon, and coffee grounds packaged in sealed galvanized cans to prevent spoilage, dampness, and external gases.2 All of the ration kits provided to soldiers went through multiple iterations throughout the next 70 years, but remained in cans up until the implementation of the MRE in the early 1980s.

"I joined the Army back in 1983 when they were developing the MREs, and we were still eating the canned rations that were the same ones from the Vietnam War, so it was phenomenal to get these things in flexible pouches that you could put in your pocket and not have cans rattling around," explains Chief Accetta, a retired Army lieutenant colonel. "In fact, I remember I had cans in my pocket during a training exercise, and I had to go to the ground and got a bruise on my leg from landing on a can."

Modern MREs are usually packaged in flexible packaging and have a shelf life of approximately three years if held at 80 °F, without the need for chemical preservatives in the products' formulation.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

"We always want to tell people who aren't familiar with them [MREs] is that the shelf life of three years at 80 degrees is not due to chemical preservatives; it's due to the food processing and packaging technology that is developed here in Natick," Accetta explains.

Placing the rations into flexible packaging instead of galvanized cans made rations much lighter in weight and easier to carry, thereby reducing the load a soldier must carry during their mission. Accetta described that when he was serving in Afghanistan, soldiers had to carry up to 120 pounds of equipment and supplies, including weapons, ammunition, water, batteries, food, helmet, and body armor while traversing mountainous terrain in both hot and cold environments.

In addition to weight reduction, flexible packaging can be retorted, puncture-resistant, and effectively store food products in a variety of formats, such as liquids, gels, and bars (Figure 2). Flexible packaging also can be specifically designed to meet certain future objectives, such as being biodegradable to be more sustainable and efficiently reduce the amount of waste a soldier must haul back with them when refuse containers are not available.

FIGURE 2. The Contents of MRE Menu 2, Beef Shredded (Credit: Ashley Pomeroy, Wikimedia Commons)

Weight reduction also can be achieved by the utilization of processing technology. For example, the Soldier Systems Center can further reduce the weight of an MRE by removing water from a food product by freeze drying (technically known as lyophilization), which is the process of removing water from a product after it has been frozen and placed under a vacuum. In addition to weight reduction, freeze-dried foods will not become a proverbial brick in freezing temperatures, making it an optimal format to use in cold climates. The Soldier Systems Center is also testing the removal of water by vacuum microwave drying, which concerns the boiling point of water rather than the melting point, as is the case with freeze drying.

"You can put in an already baked item, like cheesecake, or other baked goods and dry it down further to reduce weight," explains Dr. Flock.

The Soldier Center is also testing sonic agglomeration as another means of weight reduction. The process of sonic agglomeration utilizes sound waves to bind the molecules in the food, which enables the compression of ingredients without the need for other processing aides. The ability to further compress food items enables DoD to provide soldiers with MREs that are more calorically dense without the need to include other components that do not have actual health benefits to bind ingredients together.

Research and Development

The variety of meals that will be developed for DoD by researchers at the Soldier Center are determined by those who most regularly consume them—active-duty, reserve, and National Guard military personnel. When developing MREs, researchers working at the Soldier Systems Center must consider the wide range of demographical, cultural, and religious backgrounds that exist among military personnel. To ensure that it is providing what the soldiers want, the Soldier Center offers soldiers to take surveys in which they are typically asked which variety of items they enjoyed the least. Furthermore, soldiers are asked to test and provide feedback on new items currently in development. Researchers will then use the resulting data collected to drive the next project.

One such MRE that was frequently requested, but especially difficult to develop, was pizza. It is easy to understand why it was so challenging to turn a pizza into an MRE and make it last three years when considering the organoleptic and food safety characteristics of a traditional pizza. Due to the differing amount of water activity of each component, the occurrence of water migration is possible and may lead to the growth of unfavorable molds or harmful bacteria.

"Many different iterations had to be done with the amount of sauce that can be present to allow the least amount of water migration," explains Dr. Flock.

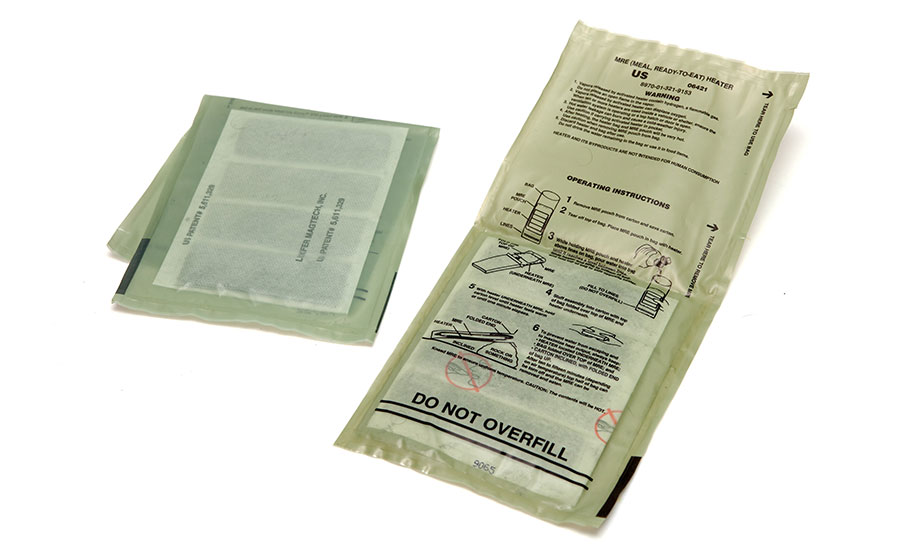

Like other MREs, successful development of a pizza MRE was dependent on the past and future development of food and/or process technologies, such as shelf-stable bread, which was developed about 20 years prior to the pizza. One can infer from our conversation about the development of the pizza MRE that, just like in the civilian world, new technologies are driven by consumer demand—which, in this case, are military personnel. One such demand was to provide the soldier with a method of warming up their food while in an austere training or operational environment. In response, the Soldier Center designed and launched the Flameless Ration Heater (Figure 3).

The Flameless Ration Heater can heat up an MRE entrée anywhere, and at any time, without the need for an open heat source such as a flame or electrical current. Instead, the Flameless Ration Heater uses a combination of food-grade magnesium, iron, and sodium to produce an exothermic reaction that is activated by the addition of a small amount of water.3 Considering the notion that troops out on tour in remote or hostile environments may not consume a hot meal for days or weeks, the inclusion of the flameless ration heater in MRE packs is a welcome addition.

FIGURE 3. A Pair of Flameless Ration Heaters (Credit: Ashley Pomeroy, Wikimedia Commons)

Having the ability to eat food while it is hot has numerous positive implications. For the soldier, it will make meals more palatable and enjoyable, thus increasing their satisfaction and overall morale. For the Department of Defense, by increasing the palatability of MREs, there is more assurance that active military personnel will regularly and more willingly consume them, consequently providing the necessary nutrients to maintain their physical capability. From a food safety perspective, food technologists at the Soldier Center still need to be cognizant about the sterility of the food-contact flexible packaging as some of the consumables included in the MRE do not go through a retort process like the entrée. Instead, safety is ensure via microbiological testing. The Flameless Ration Heater warms the entrée about 20 °F higher than the temperature of the environment, on average. Thus, dissimilar to the entrées, the other consumable components still do not go through a kill step, as the Flameless Ration Heater does not produce enough heat to effectively destroy pathogenic bacteria. This is one of the many reasons that each new MRE goes through a gauntlet of both physical and microbiological tests before it is released for consumption by military personnel.

Deciding on which project to pursue is merely the beginning of the research and development process. Before releasing a new MRE into the field, it must meet specific functional targets. Firstly, technologists must ensure that the MRE meets both sensory and safety goals throughout the entirety of its shelf life, as well as when it is stored for six months at 100 °F. Technologists use a variety of hurdles such as pH, water activity, microbiological criteria, and various temperature treatments to create a product that is safe and able to maintain its quality. The new MRE must also adhere to nutritional frameworks (i.e., daily intake of calories, vitamins, and carbohydrates) that have been determined by the Surgeon General as essential to provide optimal sustenance to military personnel involved in a multitude of different situations and tasks.

Along with having to pass numerous sensory and safety tests, MREs must pass other types of tests to ensure that each component can withstand the potential physical stresses that it may need to endure before being consumed. One category of challenge that is undertaken is drop testing. Drop tests are performed in both the laboratory and real-world environments. An MRE is dropped from a high altitude to the ground or a place of lower altitude with the goal of assessing whether or not the meal's components and packaging will stay intact after the completion of the test.

"We throw these things out of helicopters at about 100 feet, or just kick them out, and they have to survive the impact to the ground and not have all of the things break and leak all over the place. We also drop them by parachute," explains Accetta. "They will put a whole bunch of cases of MREs or unitized group rations on pallets, throw them out of the back of an airplane at about 1,000 feet, and they've got to survive that impact, which is about 20 feet per second."

Transfer of Technology

The scientific achievements made by those working in the Combat Feeding Division at the Soldier Systems Center or via military-sponsored research when developing MREs are not only applicable to benefitting the military community; they also have had a great impact on general commerce. Many of the food, equipment, and processing technologies consumers experience in today's marketplace have been spun off from research carried out by the Combat Feeding Division. When a consumer visits their local grocery store, they may be completely unaware of just how much research performed or sponsored by the military has shaped what they buy and the format in which their favorite foods are offered.

For example, many caregivers keep a "healthy" stash of shelf-stable snacks with them at all times to satiate their children or other dependents. Many of these snacks—such as protein bars, shelf-stable bakery items, or shelf-stable pouched snacks like applesauce—were either originally developed by the Combat Feeding Division at the Soldier Systems Center (in conjunction with academia and industry professionals) or manufactured using food processing technology derived from military-funded research. High-pressure processing (HPP), as an example, is a type of food processing technology that can reduce or eliminate harmful bacteria and extend the shelf life of foods and fluids using pressure rather than heat. Using pressure in place of heat mostly supports the preservation of a product's desired organoleptic and nutritional properties. Items civilian consumers purchase every day at their local grocery store, like salad dressing, packaged sliced meats, and fluid dairy products, are produced using HPP.

The MRE itself has also proved to have a significant benefit to the civilian population. Along with Flameless Ration Heaters, MREs are a popular choice for hikers and survivalists since they are lightweight and can be easily consumed anywhere. Items like meal replacement powders and bars have been used in hospitals to help people who are unable to eat get the calories they need. On a more macro scale, MREs also have been adopted for use by nonprofit organizations to fulfill the needs of those experiencing humanitarian or natural disaster crises (Figure 4).

FIGURE 4. The Missouri Air National Guard Loads 15,000 Pounds of MREs onto a C-130 Hercules Aircraft for Delivery to the City of Avon Park, Florida Ahead of Hurricane Irma (Credit: Major Jared Kirk, Wikimedia Commons)

It is astonishing just how influential to civilian life are the equipment, food, and processing technologies developed by or in conjunction with the Combat Feeding Division at the Soldier Systems Center. It is important that we as civilians acknowledge and appreciate the fact that many of the foods we freely enjoy today while "on the go" were originally designed to sustain the soldiers who have risked their lives to guarantee that freedom.

References

- Defense Logistics Agency: The Nation's Combat Logistics Support Agency. "Meal, Ready to Eat (MRE)." https://www.dla.mil/Troop-Support/Subsistence/Operational-rations/MRE/.

- Feagans, Jacob M., Darius A. Jahann, and Jamie S. Barkin. "Meals ready to eat: A brief history and clinical vignette with discussion on civilian applications." Military Medicine 175, no. 3 (2010) 194–196.

- Accetta, David. "Flameless Ration Heater Fact Sheet." US Army Combat Capabilities Development Command Soldier Center, 2020.

Jeremy Zenlea is the Director and Head of Health and Safety at EG America and a Lecturer at Northeastern University College of Professional Studies. He is also a member of the Educational Advisory Board of the Food Safety Summit, produced by Food Safety Magazine.

.webp?t=1721343192)