Advances in UV-C Light Technology Improve Safety and Quality Attributes of Juices, Beverages, and Milk Products

The growing consumption of premium categories of dairy, fruit, and vegetable beverages has been attributed to the perceived health benefits of the “all natural,” “made of organic ingredients,” reduced-calories, and reduced-sugar messages based on high levels of enzymes, nutrients, and bioactive constituents. To achieve these attributes, the products have to be minimally processed in terms of treatment temperature and exposure to oxygen. For instance, the growth of the cold-pressed juice industry from local into regional and national markets required higher stability, safety, and extension of product shelf life to at least a few weeks. Thermal pasteurization is an effective preservation technique but often negatively impacts both nutritional and quality parameters. An alternative nonthermal processing strategy is the use of high-pressure processing (HPP). However, HPP is associated with high start-up and operational costs and batch processing while also requiring a large amount of space and use of plastic packaging.

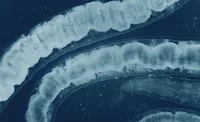

Ultraviolet-C (UV-C) light is another emerging nonthermal alternative that offers less expensive, energy-saving continuous treatment and packaging flexibility. Also, UV-C at 254 nm is effective against all foodborne pathogens, natural microbiota, molds, and yeasts, with minimum impact on quality and nutritional attributes.[1] To achieve high efficacy of UV-C processing in products with low UV transmission (UVT), such as the majority of juice and milk products, new engineering approaches have been developed that differ from those normally employed for water treatment. In case of water, UVT achieves values of 90 percent and higher; for clear juices, the UVT is typically less than 30 percent and reaches 0 for turbid juices with particles. Due to the low-UVT challenge, laminar or turbulent regimes using thin films, static mixers, or Dean flow in coiled tubes must be employed to effectively deliver light photons to the whole volume of the products.[1] The first UV system that was developed and used to generate data for regulatory submission in the U.S. in 2001 was based on coiled tubing where liquid was treated in turbulent flow and low-pressure mercury lamps that delivered a similar UV dose for a range of juice products. The current challenge remains because since the UV dose has not been established by regulators, the process has to be developed based on achieving product-specific process requirements or so-called intended technical effect. This can involve a 5-log target pathogen reduction in juices to meet Hazard Analysis and Critical Control Points (HACCP) and shelf-life extension of fresh juices, pasteurized milk, or liquid sugars by eliminating spores or spoilage organisms. This means that actual operational UV dose can vary for different categories of juices, beverages, and liquid ingredients, and very much depends on product composition, absorption coefficient, rheological characteristics, initial microbial load, and reduction requirements. Also, the UV dose should be optimized to achieve the best quality, nutritional, and sensory attributes, as shown in Figure 1. After the UV operational dose is established, its effects on enzymes and stability of juice suspension should be taken into consideration.[2]

Using a new commercial system, extensive experimental studies were conducted to establish and validate operational UV dose for a number of beverage categories such as fruit and vegetable juices, cold teas, milk products, and liquid sucrose and fructose ingredients. The new UV technology delivers light photons to the entire liquid volume when it is pumped in a turbulent flow through the polymer tubing. The use of food-grade polymer tubing in food processing facilities ensures that safety and HACCP requirements are met by eliminating the hazards associated with the use of glass. The size and geometry of the tubing along with product flow rate create a turbulent flow regime with effective spontaneous mixing. Another feature of this technology is that UV-C output power and consequently UV dose level can be adjusted for each individual product in several ways, such as using lamps with different power output and adjusting the current (amperage) of the lamp without changing the geometry of the reactor chamber (e.g., tube diameter, coil diameter, number of UV lamps, lamps’ distance from the coil). Two types of low-pressure amalgam and mercury lamps (LPA and LPM) with 320-W and 75-W outputs were tested for specific applications. In the system tested, the UV irradiance is measured and controlled with two UV sensors. The UV-C sensors are installed in the chamber considering geometry of the tube and direction of the incident UV light of surrounding lamps. This allows not only monitoring of the UV-C irradiance but also accurately measuring the output power of the lamps and precisely evaluating the absorbed dose delivered to the treated product. Products’ recipes can be saved in the system program and also can be used to adjust the UV dose levels for individual products. Temperature sensors control air and product temperatures in the UV-C chamber.

Operating UV-Processing Conditions

Developing a new UV-based process requires first establishing a proper operational dose, a validation step to ensure that proper UV dose is reliably delivered to the product, and evaluation of the microbial efficiency of a system. The examples of six processing conditions at different output power levels that can be achieved in the system are shown in Table 1. The Keitz approach[3] was used to calculate the total UV output power from UV lamps with a monochromatic output at 254 nm.

Applications: Juices

Cold-pressed fruit and vegetable juices compose a growing market of premium juice products due to their high nutritional content and health benefits. Cold-pressed juices are treated using nonthermal technologies that are considered more advanced chemical- and heat-free processing options. As was shown previously,[1] UV technology is effective against common pathogens of concern in juices, natural microflora, molds, and yeasts, and extends shelf life of juices such as popular leafy greens products and fruit-and-vegetable blends, while using various types of glass packaging. Additionally, tests for evaluating compliance with HACCP 5-log reduction requirements with regard to inactivation of pertinent pathogenic organisms were performed. A variety of juice products from fruits, berries, leafy greens and vegetables, and black and green tea inoculated with different types of bacteria (Escherichia coli ATCC 35208, yeasts, and Bacillus atrophaeus spores) were treated at throughput of 1,000 L/h (4.4 GPM) and 100 percent of UV power output of 308.8 J/L with all UV lamps turned on. Particularly, the tests were conducted using 10 types of high-acid juices (pH < 4.6) including apple (clear and turbid), orange (clear and turbid), tropical, cherry, blueberry, cranberry, and grape juices. Additionally, five types of low-acid juices (pH > 4.6) were tested, such as coconut water, sea buckthorn juice, carrot, wheat grass, and celery juices, plus black tea.

The results of juice microbial challenge tests with E. coli ATCC 35208 showed that UV treatment could achieve a range of logarithmic count reduction (LCR) between a minimum of 5.0 in tropical juices and 8.1 in clear apple juice. The LCR of E. coli bacteria in fruit juices obtained as an average of all tests is shown in Figure 2, demonstrating that UV treatment achieved higher than 5 logs in all tested products.

Treatment at 100 percent UV-C exposure resulted in a reduction in the total counts of natural microflora in green-blend juices including acid-uric and aerobic total counts of 3.7 and 3.9 logs, respectively, as well as 2.1 logs for both molds and yeasts. E. coli, lactic acid bacteria, and coliforms were not detected in any of the green-blend juice samples treated with UV-C.[2] UV-C treatments ranging from 27.7 to 308.8 J/L have led from 1.0- to 3.0-log count reductions in these microorganisms in fruit juices. Additionally, the UV treatment was effective against B. atrophaeus spores in sea buckthorn juice and coconut water by achieving averages of 5.6 and 5.4 LCR, respectively.

Milk

UV treatment is also a promising technology for dairy processors as a safe, energy-efficient, and economical process to gain added value. UV treatment can be successfully employed as an alternative method of post-pasteurization to reduce the microbial count beyond normal pasteurization and increase shelf life of pasteurized milk by at least 30 percent under refrigerated conditions. The main goal of the combined process is to achieve an extended shelf life (ESL) of milk without exposing the milk to the high temperatures and packaging under extreme hygienic conditions that are common in regular ESL treatment. Extensive research showed that UV treatment of whole cow and goat milk was effective against aerobic microflora, E. coli, Bacillus cereus, and Bacillus subtilis spores, as shown in Table 2. The effect of two UV-processing conditions at 100 and 20 percent energy levels was tested due to concern about off-flavor formations in milk products.

The higher UV energy level resulted in the higher log count reductions of all types of organisms tested. The more efficient inactivation of natural bacteria, E. coli ATCC 35208, and B. cereus spores of more than 5 logs was observed after treatment at 100 percent UV energy levels in cow milk. The LCR of B. cereus spores was lower in goat milk (Table 2). A triangle test (nine-person panel) was used to determine whether there was a noticeable difference in sensory qualities between cow milk samples treated at energy levels of 100 and 20 percent. It was found that subjecting cow milk to the higher UV energy input resulted in off-flavor formation. No noticeable changes were found by the majority of professional tasters when pasteurized cow milk was treated with UV light at 20 percent of full energy level or 2.31 J/L.

Sugar syrups

UV technology can be of great value in products that are using syrups such as liquid sucrose, fructose, and other sweeteners, and can replace traditional heat treatments. Although liquid sugars and sweeteners are characterized by high viscosity, UV processing was found effective against not only common pathogenic organisms and high UV-resistant spoilage microflora such as yeasts and molds but also against microbial spores. No formation of undesired chemical compounds such as furans that can be potentially promoted during UV exposure was reported at the applied UV doses range. The results of the tests of liquid sucrose with 60° Brix at 20 °C are summarized in Table 3.

The UV treatment of liquid sugar was most effective against E. coli, resulting in more than a 7-log count reduction. Yeast, molds, and B. atrophaeus spores had higher UV resistance, and the UV output powers of at least 172 and 250 J/L were required to achieve 5.1-, 3.6-, and 4.2-log reductions, respectively.

Therefore, testing of novel UV technology at an industrial scale demonstrated its feasibility for a variety of commercial applications in the beverage, juice, and dairy industries. The challenge is to achieve specific safety and shelf-life objectives for products in the broad UVT, viscosity, and pH ranges, with variations in UV resistance of target organisms and photosensitivities of product compositions. The summary data of products and process parameters demonstrate how product-friendly solutions can be developed to achieve desired technical effects by adjusting lamp output power levels, resulting in additional energy savings. The examples of products tested and established processing conditions are shown in Table 4. A 5-log reduction of pathogenic E. coli bacteria was achieved in all tested products with no noticeable changes in quality, nutritional, or sensory attributes. To achieve an extended shelf life, a higher operating UV dose can be required to reduce numbers of molds and yeasts or bacterial spores that can survive pasteurization. To avoid photodegradation effects in milk, UV sources with the lower output power or amperage can be used to eliminate off-flavor formation. Advanced built-in features allowed modifying UV source output and consequently power levels.

Existing Regulations

Another advantage of UV-C technology for juice and milk products is that it has been approved by the U.S. Food and Drug Administration (FDA), Health Canada, and the European Food Safety Authority (EFSA).[4–6]

• 2000: FDA amended the food additive regulations to provide for the safe use of UV radiation at 254 nm to reduce human pathogens and other microorganisms in juice products. It was determined that the amount of UV irradiation necessary for human pathogen reduction would depend on the type of juice, the initial microbial load, and the design of the irradiation system (e.g., flow rate, number of lamps, and time exposed to irradiation). Therefore, FDA did not specify a minimum or maximum UV dose by regulation but concluded that this should be achieved for individual usage situations in a manner consistent with Good Manufacturing Practices.[4]

• 2004: Health Canada determined that there are no safety concerns, and it has no objection regarding the sale of UV-treated apple cider to achieve a reduction in the microbial load of apple juice and cider products.[5]

• 2016: EFSA concluded that UV treatment of pasteurized milk to produce ESL products and increase vitamin D content is safe under the intended specified conditions of use, which opened new opportunities for further technology commercialization in dairy applications.[6]

• 2017: The Israeli food regulations agency approved the use of UV light to reduce microbial load in pasteurized milk. The health committee approved an application to treat pasteurized milk with UV light at 200 to 300 nm using a turbulent flow regime. The treated milk must be free from microbial contamination and will be labeled according to Israeli regulation as “UV-treated” and will be subjected to any changes in the regulation.

• 2018: Health Canada concluded that juices processed with UV technology are not considered novel foods and are safe for consumption since there is no major change in nutritional composition and chemical safety at maximum 100 percent energy level delivered to the product in one pass.

Conclusion

The regulatory status of UV-C light treatment emitted by LPM lamps at 254 nm for juice and dairy products, and the growing premium beverages market, opens new opportunities for the further development and commercialization of this technology at industrial scale. Food processors who wish to invest and test this technology should understand the advantages and limitations of a UV light-based process. By monitoring product parameters, the UV treatment conditions can be tailored to avoid overprocessing and developing off-flavors. UV processing systems should also be integrated into the line to avoid cross-contamination and achieve maximum product shelf life.

Tatiana Koutchma, Ph.D., is a research scientist in novel food processing at Agriculture and Agri-Food Canada. She is on the graduate faculty at University of Guelph, Ontario, Canada, a member at-large of the Nonthermal Processing Division of the Institute of Food Technologists, and Canadian Ambassador to the Global Harmonization Initiative. The author thanks Motti Coren and Dror Livne of AseptoRay for sharing data and equipment.

References

1. Koutchma, T, et al. 2016. “Effects of Ultraviolet Light and High-Pressure Processing on Quality and Health Related Constituents of Fresh Juice Products.” Comp Rev Food Sci Food Safety 15(5):844–867.

2. Biancaniello, M, et al. 2018. “Feasibility of a Novel Industrial-Scale Treatment of Green Cold-Pressed Juices by UV-C Light Exposure.” Beverages 4:29–44.

3. Keitz, HAE. Light Calculations and Measurements (London: Macmillan and Co. Ltd., 1971).

4. FDA. 2001. “21 CFR Part 179. Irradiation in the Production, Processing and Handling of Food.” Fed Regist 65:71056–71058.

5. www.hc-sc.gc.ca/fn-an/gmf-agm/appro/dec85_rev_nl3_e.html.

6. www.efsa.europa.eu/en/efsajournal/pub/4370.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

.webp?t=1721343192)