Fonterra’s Food Safety Transformation

Fonterra is a global dairy nutrition company sharing the nutritional benefits of dairy with over a billion people every day. It’s a cooperative made up of around 10,000 farmers and 22,000 people, working alongside partners, suppliers, customers, and consumers, and headquartered in Auckland, New Zealand. It’s the largest exporter of dairy in the world, with product going to over 100 countries. As well as fresh milk, the company produces ingredients for the consumer and foodservice industries, plus ingredients used in everything from advanced medical nutrition to everyday dairy products to infant nutrition to milk powders.

The dairy industry has been part of New Zealand since the 1800s, with the first dairy cooperative established in the South Island in 1871. Fonterra was formed in 2001 when two of New Zealand’s largest dairy cooperatives merged with the New Zealand Dairy Board to create Fonterra. The Cooperative has an annual turnover of around NZ$17 billion, with a core ingredients business exporting under the NZMP brand, as well as fast-moving consumer goods businesses globally. Currently, it has 51 operations sites in 11 countries across five continents and sources milk from Australia, China, Latin America, New Zealand, and Sri Lanka.

Putting a Strong Focus on Food Safety

The importance of creating a strong and sustainable culture around food safety and quality (FSQ) was highlighted in August 2013 during a precautionary recall of a whey protein concentrate product (WPC-80). WPC is used in a variety of ways, including in yogurt, beverages, and dairy desserts. It is also used in infant formula and sports nutritional supplements. During extensive product testing, Fonterra had concluded there was a minute potential food safety risk with three batches of WPC-80. Further testing showed there was no risk to consumers, but in the interim, Fonterra contacted its commercial customers and publicly announced a precautionary recall.

This precautionary recall prompted Fonterra to look more closely at its practices and beliefs around food safety, resulting in a recognition that the food safety culture could be stronger, and the predominant focus was on milk processing and operational efficiency. As a result of this reflection, a 5- to 10-year FSQ strategy was developed, with the objective of fundamentally changing the mindset and behavior of the business.

This strategy is called “Trust in Source,” and through it, Fonterra is constantly focusing on reducing risk, building trust in its people, customers, and consumers, and in the food it produces, as well as creating value for the business.

To do this well, the Cooperative started with its customers and consumers, taking on broader insights from global communities to understand what matters most to them. As a result, the Trust in Source strategy starts with consumers and what they need to ensure they can trust the food Fonterra is making, that it meets their expectations, and then works right through Fonterra’s entire supply chain back to the farmers, vendors, suppliers, and other key stakeholders (Figure 1)..png)

Changing the Food Safety Culture

The 2013 event sparked a number of immediate actions. Fonterra showed early commitment by recruiting dedicated, specialized personnel to lead the food safety culture transformation and ensuring they had access to globally recognized thought leaders in this field, such as Frank Yiannas, then the vice president of food and safety and health at Walmart. Alongside learnings from Fonterra’s existing strong health and safety culture, the Yiannas model was adopted as a cornerstone of the Trust in Source transformation program (Figure 2).

Team members were recruited as specialists in change management, human behaviors, marketing, and adult learning and communications. Having a dedicated team was a deliberate decision made by the CEO and Fonterra management team to ensure a single-minded focus to make and sustain the change to having the desired food safety culture.

The team developed measurement systems in partnership with Frank Yiannas to measure the maturity of the food safety culture within the organization. From this point, plans were cocreated with business unit leadership teams that reflected the teams’ individual cultures. This enabled the teams to leverage the creative tools, science, and capabilities to deliver a balance of company-wide and specific initiatives and engagements to make the transformation to a sustainable food safety culture. Today, the Fonterra management team and board receive regular reports from the FSQ team regarding delivery on its strategy and the maturity of Fonterra’s FSQ culture, with significant progress being demonstrated over the past few years.

Showing Evidence of Positive Changes

Not only have Fonterra’s internal metrics shown improvement, but feedback from its customers demonstrates that these changes are also making an impact. For example, last year, independent research benchmarking showed that Fonterra’s customers in total believed that every product group produced was performing at or above a world-class standard, with feedback such as:

“Fonterra products stand out in terms of the quality (product performance) when many products are compared together. A high level of customer loyalty can be seen because of such excellence in quality.”

“Works very closely with customers to understand issues, needs, and processes to improve service level of performance and build long-term relationships.”

Key to the speed at which the culture shift happened was strong, focused leadership partnered with a dedicated team that leveraged a broad range of approaches to maximize the impact, uptake, and integration of the desired future behaviors. The aim was to build a strong and thriving culture throughout the workforce and beyond, integrated into the “business as usual” workings of the organization to ensure sustainability.

Consistent communication then concentrated on two key areas:

1. Making FSQ a personal focus on what it means to “me” and not an amorphous “business priority.” This is best exemplified by the “safety is a promise” campaign that Fonterra continues to build on while also integrating into regular business activities such as on-boarding, training, and communications. This campaign encourages every employee—from the senior management team down—to make their own personal safety-related commitments and promises. It is enhanced through stories such as that of John, a forklift driver at the Kauri factory in Whangarei, and supported through additional branding and collateral such as the promise walls at all factory entrances, red-line promise statements in staff changing rooms, and regular stories shared across the organization, all bringing the concept of personal responsibility into the everyday work environment of the workforce.

2. Growing the understanding of what being a food company means. Fonterra has significantly changed the understanding about what it does. Rather than processing a “wall of milk” to different specifications, Fonterra recognizes that its products are either ingredients in food or food items themselves and are eaten by people all over the world. Simple engagements—sharing food, telling stories from customers and consumers, producing maps for each factory of where their food goes—all contributed to this shift. In addition, Fonterra had the opportunity to create a step-change engagement from the start of the 2015 season (July 2015) using a “supply chain experience” that now includes virtual reality, filming, and gamification to provide a variety of ways to communicate to and engage various audiences. Fonterra’s employees can now speak with consumers who eat the food they make and hear why they chose to buy food made by Fonterra and the impact that has in their lives.

Sustaining the Changes in Food Safety Culture

Three things have made the most difference in creating our sustainable food safety culture:

1. Driving Leadership and Commitment

This was driven initially by the precautionary recall but has been sustained since 2013 through a deliberate approach of ensuring regular and ongoing reporting, cadence around engagement, and support as asked for from the Fonterra management team to lead the way while modeling the behaviors it is seeking. This is supported with strong governance for FSQ, including a range of technical stakeholders and business leaders. It included spending time with the management team and senior leaders to clarify Fonterra’s FSQ expectations and then leveraging these as the “true north” or “guiding light” for all forthcoming FSQ decisions and behaviors. In addition, it tapped their keenness to engage on this topic on a global basis by participating as a member of the Consumer Goods Forum’s Global Food Safety Initiative Technical Working Group on Food Safety Culture, workshops, and presentations at conferences and industry-wide events, working alongside Fonterra’s vendors and partners on their own food safety culture strategies as they see the benefits in learning from others and sharing their stories.

2. Understanding Its People

The transformation team understood that to change behavior, it had to engage people in a way that would reach them and not maintain one style of communication or approach. The challenge was to identify the audiences, what mattered to them, and how the team could reach them. The team was also faced with an audience that had been through a lot of change. It needed to find a way to resonate with them all, quickly and on a global scale.

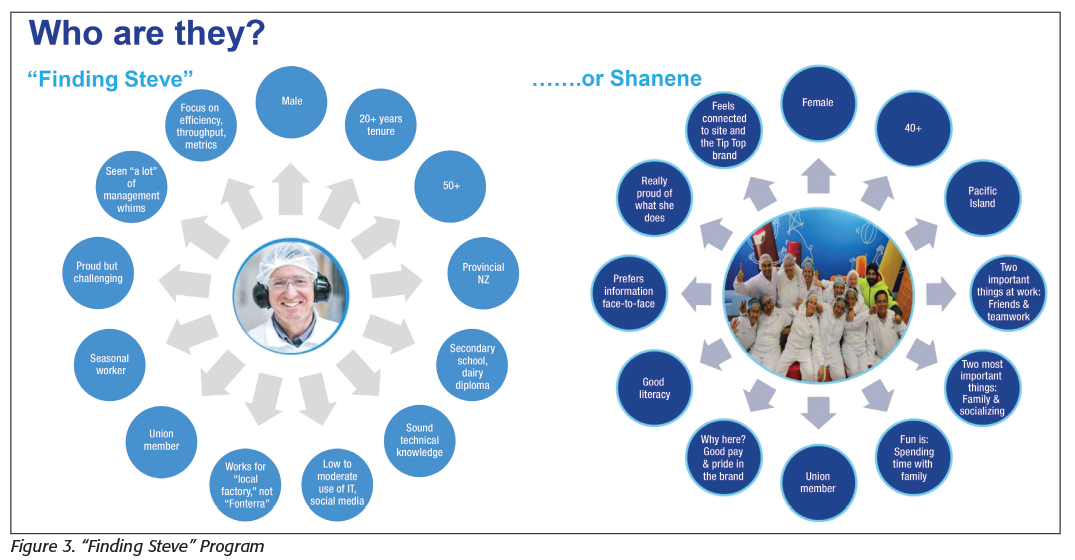

The program was nicknamed “Finding Steve”—and in finding Steve, the business gained an excellent understanding of the attributes, behaviors, and states of mind of key audiences in building the food safety culture the team was looking for (Figure 3).

“Finding Steve” leveraged the customer segmentation concept used in marketing. It was based on gathering data, holding focus groups, talking to key stakeholders such as unions, and getting an overall picture of the workforce the team needed to engage with. The process began in 2014 with the New Zealand manufacturing worker (the original “Steve”) and will continue as a key enabler to sustain the change. Through this process, the team discovered a number of distinct people profiles across Fonterra’s global business. These profiles formed the basis of the decisions made as to the methods of communication with various business units, sites, and operating entities. This allowed the transformation team to cocreate and test initiatives with particular “Steve” groups, so that when they deploy something, they know it will resonate with the target audience, minimizing ineffective communication and avoiding food safety communication becoming “white noise.”

3. Leveraging Science, Creativity, and Innovation

Through leveraging the science of human behavior and taking a creative and innovative approach to problem solving, Fonterra delivered initiatives that were compelling and connected to its people. One example of this was through engaging an adult learning specialist with one of Fonterra’s key business partners, Sysdoc. By working alongside their learning team, the approach to annual food safety compliance training was revolutionized. Together, a very procedural slide presentation with low learning outcomes was turned into an engaging board game, which was visually customized to build rapport with its audience. This board game method has proven to deliver strong learning outcomes but also to be far more than just an educational tool; it directly impacts the culture and behavior around food safety as a result of the design and the people who facilitate it. Consequently, the relationship between food safety roles and the operators within the business has become far more transparent. The game not only encourages but also legitimizes the discussion of tough topics—topics that might otherwise be avoided in the presence of the FSQ specialists. From a behavior and culture perspective, this relationship dynamic change is hugely powerful, and operations staff now approach the group food safety team, without prompting, much more frequently.

Moving Forward as a Better Company with a Stronger Food Safety Culture

Fonterra’s new level of commitment to FSQ has led to a change in behavior so significant that its customers and partners use language to describe it—“old Fonterra” versus “new Fonterra.” Feedback from customers and quotes that are shared within the business are largely consistent and positive as to the change in attitude, results, and focus that people have perceived toward FSQ. This is entirely down to the underlying cultural and behavioral changes that continue to drive the business changes people are noticing.

The strength of this food safety culture is evident not only expressly in artifacts, policies, and procedures, but also intrinsically in the values and beliefs of people at all levels of the organization. Independent research has recently demonstrated that Fonterra employees now better understand their individual responsibilities as part of a food company and are better empowered, encouraged, and enabled to “stop the line” or make the right call for the safety of Fonterra’s people and the products they are making.

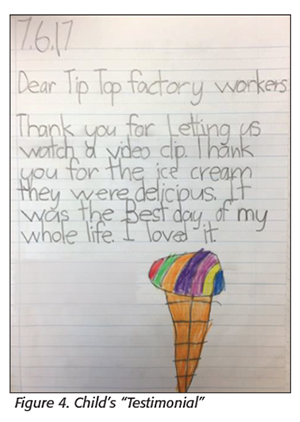

But most importantly, why Fonterra does this is outlined in Figure 4.

Joanna Gilbert is the Director, Reputation Shift, Corporate Affairs, for Fonterra Cooperative Group Limited in Auckland, New Zealand.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →