Automation Series

The challenges of upgrading legacy control systems

A legacy control system may be running just fine, but processors need to be prepared to replace it

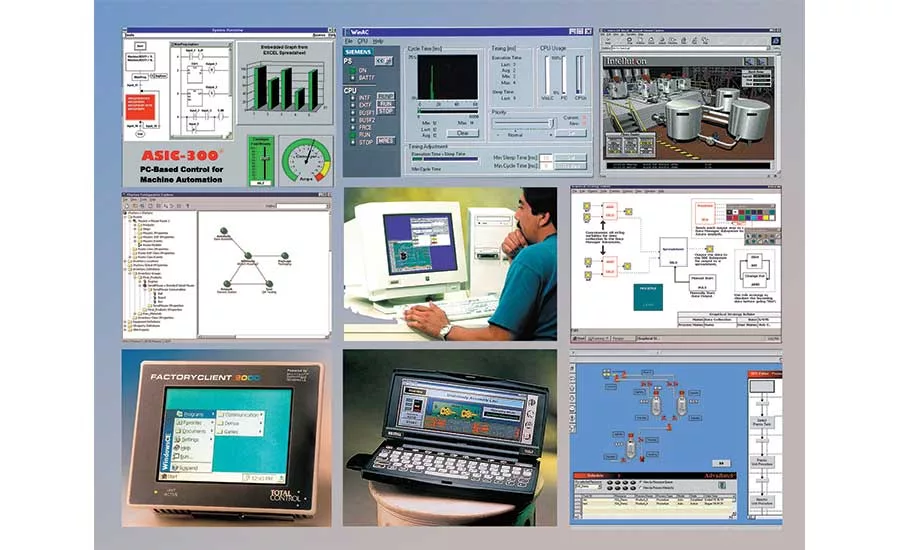

Do you remember these—or are you still using them? Not all these companies exist today, and many have been merged into larger companies. (Starting upper left, and moving clockwise): ASAP’s ASIC-300 machine automation software; Siemens SIMATIC WinAC for Windows NT/2000, supporting OPC; Intellution’s FIX Web server HMI; Nematron’s Paragon SCADA for Windows 95/NT and IBM OS/2; Citect for Windows connects via MS ActiveX with ABB’s Advabatch, GE Fanuc CIMPLICITY on Windows CE; Total Control’s FactoryClient 2000 for Windows CE; USDATA’s Xfactory; (and center): Foxboro’s I/A Series DCS with OPC for Windows and UNIX.

Photos Courtesy of Wayne Labs

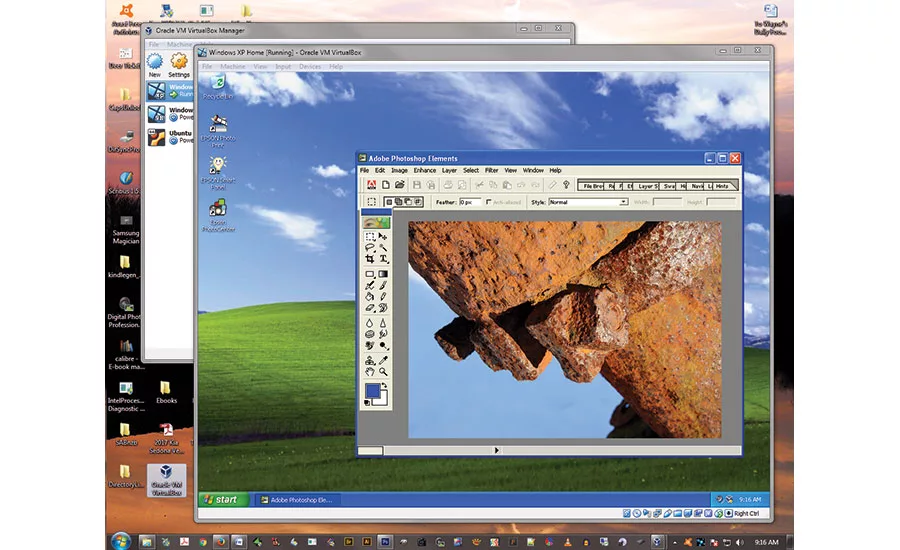

Oracle’s VM VirtualBox allows Windows XP (or other OS) along with its associated applications and drivers to run as a guest (virtual machine) on a Windows 7 (64-bit) host OS, retaining connection of Windows XP-related hardware and drivers so they can communicate with the host machine and rest of world.

Photo courtesy of Wayne Labs

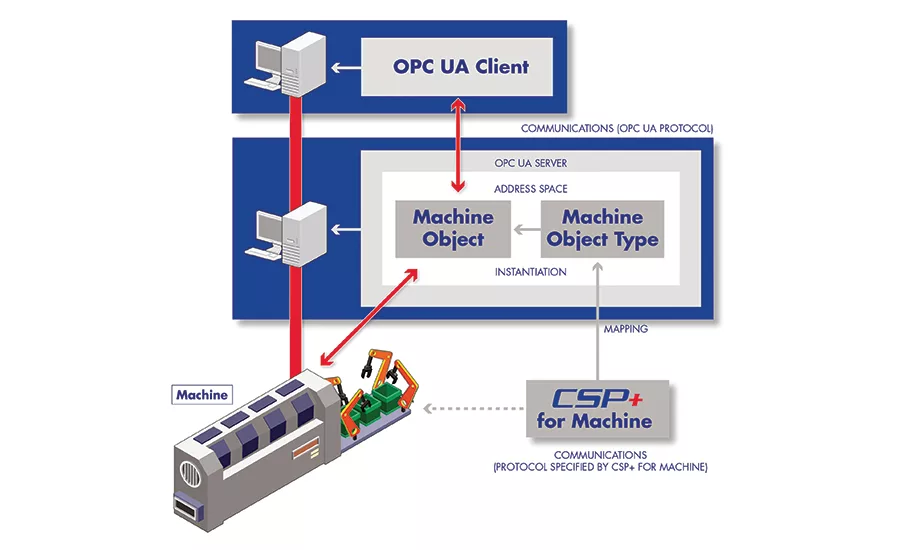

Earlier this year, the CC-Link Partner Association (CLPA) in association with the OPC Foundation, announced an OPC UA companion specification for the CLPA’s new “CSP+ for Machine” technology to further ease implementation of Industry 4.0 applications. The diagram is a depiction of an application from CSP+ for Machine-to-OPC UA Server.

Photo courtesy of CC-Link Partner Association

Obsolete controls a thing of the past at this dairy

Agropur dairy’s Don Mills, Ontario facility is its largest and pasteurizes, processes and packages enough dairy products to fill at least 30 trucks per day. Throughout its more than 50-year history, the facility collected an assortment of industrial technologies. While the mix of production equipment kept running, management couldn’t produce the seamless data necessary to improve operations continuously.

“Transforming data into information was a completely hands-on process,” says Headley Hamilton, industrial process manager. “All the requests from operators and managers throughout the year required 2,500 hours of manual, post-shift data entry. And demand was growing. When I considered the future of the facility, I knew we needed modern technology.”

Data collection wasn’t the only problem. Some of the automation technology was nearing obsolescence. Hamilton received calls nearly every day from operators reporting equipment issues or downtime. He was too busy putting out fires rather than focusing on automation improvements.

In case a system crashed, Hamilton needed to reboot from the latest backup. The question was: Where was the latest version of the system? “With seven maintenance laptops across the facility, there was no way to know whether or not you were rebooting with the most recently modified program. Not only did that take time, but so did calling every contractor to make sure you had their changes,” says Hamilton. The old system was backed up only once a quarter, and that took an additional 48 hours each year.

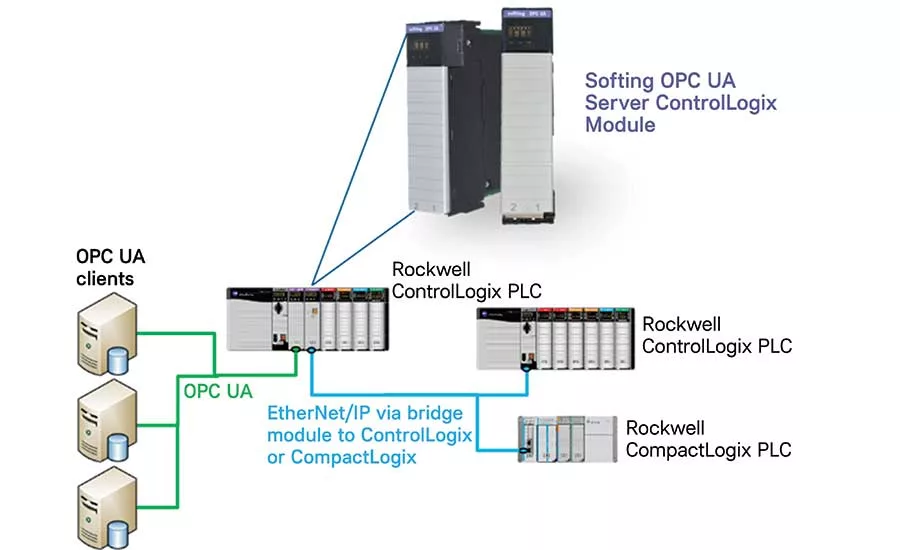

To drive continuous improvements, it was obvious to Hamilton that the facility needed a standardized plant-wide platform solution. “We decided to implement an integrated control and information solution from Rockwell Automation, because we saw it as the best solution for modernizing our facility,” says Hamilton.

The platform’s base included the Allen-Bradley family of ControlLogix controllers, PowerFlex drives and PanelView human machine interface (HMI) hardware from Rockwell Automation. Each HMI ran FactoryTalk View Site Edition software from Rockwell Automation on a virtualized server, establishing the standard for all additional software. This created the foundation for converting reams of data into actionable information.

To obtain OEE metrics, FactoryTalk Metrics software was installed, and collected performance data to provide Hamilton and his team with the data then needed to make informed decisions about the operation. An aggregation and analysis system was also installed to help operators visualize data across the facility and provided reports as needed.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

To maintain a single version of the system, Agropur installed FactoryTalk AssetCenter software to manage automation assets and version control plus keep up-to-date documentation. The seven maintenance laptops were reduced to one. With initial controls and OEE deployments, Agropur installed Rockwell’s VantagePoint software, which provided a new level of access to all data from disparate systems across the entire facility.

Improvements: 2,500 hours of manual data acquisition eliminated; 48 hours per year were saved in managing assets; a 30 percent reduction in lube consumption was achieved. Information is now available when and where its needed; and with FactoryTalk Metrics software, on one filler, efficiency was improved by 25 percent over a three-month period. Visibility was key to reducing downtime.

.webp?t=1721343192)