Fabulous Food Plants

Food quality, employee safety reign supreme at Seaboard Triumph Foods

This Fab Food Plant began operations in September, 2017 with a fully staffed first shift, processing 10,500 hogs per day

Seen at night, Seaboard Triumph Foods’ new facility in Sioux City, IA will up its processing to 21,000 hogs per day when its second shift begins work in October.

All photos courtesy of Mark Ballogg for Ballogg Photography

The plant’s lobby provides a well-lit, open feeling.

There is not a single aspect of the Seaboard Triumph Foods (STF) pork processing facility in Sioux City, Iowa, that does not pay attention to detail.

Take, for example, the humane, livestock barn and handling areas approved by Dr. Temple Grandin. Or the interior spaces of the building, linked by more than three miles of an automated conveyor/rail system and coupled with a data collection system that knows the origin (specific farm) and destination of every product it carries from the harvest floor to carcass chilling, then to carcass disassembly, final cuts (cut floor) and finally packing. In addition, robotic systems do precise cutting and trimming more accurately—and safely—than humans. And there’s not a single portion of the hog that’s wasted—“except the squeal,” says Mark Porter, STF chief operating officer.

Article Index:

Yet there’s still so much more to the story that makes this a Food Engineering FAB food plant. Designed and built by A. Epstein and Sons International Inc., STF’s new facility comprises more than 925,000 sq.-ft., made up of the main plant and other utilities necessary to function efficiently. Already operational with its first shift, and currently hiring staff for its second shift, STF will employ more than 2,000 people (including management and management support) when second shift hiring ends later this year, says Porter. With the first shift, the facility now processes 10,500 hogs per day, and that number will double upon total deployment of the second shift’s personnel.

The current employee population is nearing 1,600, and the second shift already has 200 people on line, with more in the training process, says Porter. Currently, people on the second shift are doing some specialized tasks until the shift is fully staffed and ready to begin work, which is scheduled for October 15th. Porter says that hog processing on the second shift will get total production up to between 20,000 and 21,000 hogs per day.

Seaboard Triumph Foods, LLC, is an equal ownership joint venture between Seaboard Foods and Triumph Foods, LLC. Triumph Foods is owned exclusively by pork producers, and Seaboard Foods is a wholly-owned subsidiary of Seaboard Corporation. Seaboard Corporation owns an existing facility in Guymon, Okla., and Triumph Foods owns an existing facility in St. Joseph, Mo. Both facilities are currently maxed out in production, and STF needed another facility to keep up with an insatiable demand for pork products.

The new facility produces pork products for retail, international, food service and further processing markets. It also produces fresh pork for the PrairieFresh Premium Pork and Seaboard Farms brands, as well as supplying Daily’s Premium Meats with raw materials for its premium products, including raw and precooked bacon.

Fast Facts About STF's new Plant

The need for growth

Not only were the Guymon and St. Joseph facilities running out of capacity, but the producer-owner farms were growing hogs at a rate faster than the combined facilities could handle. Therefore, the new Sioux City facility was designed to run at maximum hog conversion speeds, effectively increasing the overall throughput of the two companies by 50 percent. In addition, according to Porter, the three facilities are connected via a network backbone, allowing the companies to be much more responsive to customer needs and communicate with their pork growers.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Porter estimates that 66 percent of the hogs coming to the Sioux City plant will be supplied by Triumph Foods producer-owners and Seaboard Foods farms. The remaining hogs will be sourced regionally and follow STF’s animal care and environmental stewardship practices. This common commitment to seeking a better way to produce wholesome pork also fits into STF’s mission and strategic plans, and is in keeping with the high standards established by the two companies.

A quick overview of the facility

STF’s facility was designed from the ground up to be humane in treatment of the animals it receives prior to slaughtering, and to use automation in such a way that it removes drudgery and unsafe work from associates while providing exact measurements and cuts of carcasses and pork bellies. The automation system also provides a complete track-and-trace record of every hog that is processed—including the hog’s farm origin—as well as on what shipments its products leave the premises.

To attain such a level of accuracy in the cutting stages and in the tracking system, multiple vision systems are used throughout the process. When combined with robotics, these systems improve product yield and reduce waste.

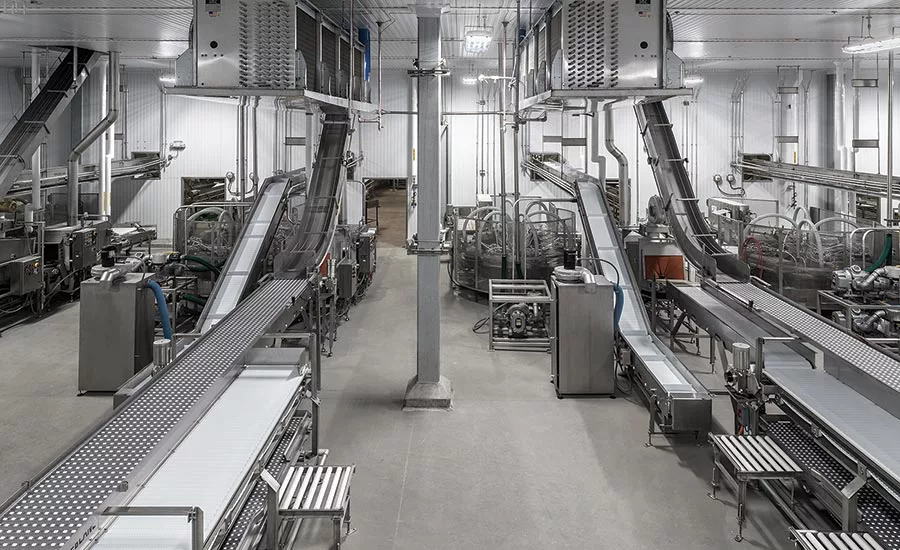

Sanitation principles are implemented throughout the facility, including automated equipment and conveyor wash systems capable of delivering a total of more than 3,000 gallons per minute of wash-down flow to all areas of the plant. Robust rendering and wastewater treatment systems serve to maximize profitable waste recovery while meeting or exceeding all required environmental standards for the plant.

The STF facility also features a wide variety of refrigerated spaces, including a -22°F snap chill room, multiple 26°F equilibration bays, a 24°F fresh product storage space, and a 40°F loading docks for outbound shipments.

In addition to the main facility housing the processing area, the plant also includes external buildings, including a rendering facility, a steam boiler/powerhouse building, an ammonia refrigeration engine room, a guardhouse security building and a wastewater pre-treatment facility.

Tried and tested automation/innovation

The basic sequence of operations in STF’s facility consists of four major steps:

- Stunning

- Exsanguination/evisceration/organ removal (harvest floor)

- Carcass chilling

- Carcass disassembly into the final cuts (cut floor)

As a buffer area for incoming livestock, stockyards were designed to provide comfort and reduced stress for the animals. “It’s hard not to mention the design of our incredible stockyards,” says Porter. “With the help of Dr. Temple Grandin, our stockyards area includes many upgraded features, including curved walls, no 90° turns, non-slip and non-glare flooring, built-in exhaust system for odor control, seven total unloading chutes and low sprinkler system. The sheer size of the area alone allows us the ability to hold up to approximately 9,000 hogs at one time if needed.”

Though a barn and holding pens were designed to minimize stress for the animals, Porter notes there is rarely a time when hogs are held longer than four hours. In fact, he says that in most cases, they begin the stunning process within two to four hours of delivery. The stunning process is a semi-automatic system capable of delivering carbon dioxide in a 30-ft.-deep pit where hogs are rendered unconscious before entering the exsanguination process.

Next, carcasses are de-haired, followed by opening the carcass and recovering the internal organs for product streams, including casings and pet food. Multiple, high-sensitivity cuts exist in the evisceration process. When initially opening the carcass for organ removal, an entire carcass can be condemned if the cut breaches specific organs. Here, robotic vision systems are used to scan each carcass and establish the appropriate cut profile, then articulating robots act on the scan data to perform the cut. Similar systems are used for head removal and carcass splitting.

Wherever automation has been applied to the process, it is carefully studied to determine a verifiable business value. Business drivers for applying technology include animal welfare and traceability, data collection and its plant-wide application, critical/high sensitivity process steps and value optimization/recovery.

“There are a number of jobs not yet fully automated,” says Porter. But the prerequisite to automating any task is that it improves the safety of employees and continues to deliver high-quality pork to STF’s globally diverse group of customers. One upgrade in the works is a robotic system for spinal cord removal, says Porter. Robotics are used throughout to do many cutting and trimming operations, and while the automation makes a worker’s life easier, it also has real business value. “The harvest floor contains many of our robotics, including a pair of neck trimmers, three belly openers and two back-split saws,” says Porter. “All of the robotics mentioned improve precision for increased yields, a better quality product overall and a safer work environment for our employees.”

On the harvest floor, automation pays off in moving carcasses to—and handling them in—the carcass coolers. Porter says he has just one operator in a cooler. Typically, a plant like this would have 12-14 and maybe as many as 16 people per shift doing nothing but pushing carcasses on and off rails. The automation keeps workers safe from handling heavy loads in a cold environment.

On the cut floor, robotics performs sensitive operations. While much of the automation isn’t necessarily new to the industry, nevertheless, STF benefits from advancements—like the Autoline automated belly trimming operation where its 3-D vision system scans and optimizes the trim cuts to make, and water-jet cutting at 60,000 psi follows the roadmap set out by the vision system. Porter says that while this is a heavy lifting and intense job for humans, it also requires high skill in making trimming decisions. Here, the machine wins every time in optimally cutting bellies that command top dollar from bacon manufacturers.

STF also automated the loin pulling, says Porter. That’s where the bone in the loin is separated from the spare ribs in the belly. This is one of the most demanding jobs in a plant—requiring a high skill level as well as being a heavy-lifting and intense job. While this automation is not new to the industry, STF again benefits from the latest developments.

While some primary packaging can be automated, with equipment such as Cryovac machines, there are other areas still requiring the manual placement of product into cartons because, as with any agricultural product, size and shape may vary, says Porter.

Once boxes are filled, the rest is automated. “Our box shop can be found on the second floor above the primary packaging area,” says Porter. “Our facility does use semi-automated cartoning. Employees place pork products in specified boxes, but the box handling system is automated.”

Once the box is closed, it gets labeled with information provided by the Carlisle data collection system, which tracks and traces every product throughout the plant. Then the product is routed to exactly where it will be palletized. And the palletizing stations are located close to where the product will be put, either for storage or handling. Any travel distances are kept as short as possible, minimizing handling.

Data collection from start to finish

Just as important as the labor-saving automation is the plant-wide data collection system, which not only serves as the facility’s nervous system, but also connects to the Guymon and St. Joseph facilities. With five major checkpoints throughout the process, the fully integrated system provides traceability on every carcass from the farm, then downstream to finished goods, says Porter.

Data collection on an individual carcass begins after de-hairing. Once mounted on the gambrel rail system, each carcass passes a station with an ultrasonic imaging device, which scans, analyzes and stores carcass characteristics, such as weight, lean meat percentage, etc. In addition, the scan’s output data is used to optimize yield of the primal cuts (belly, loin, ham, shoulder) and other components. This is accomplished in the cooling step between evisceration and final carcass disassembly.

Through the use of automated sorting into one of 99 holding cooler lanes, data tied to each carcass entering the cooler is accessed by the cooler control system, and a lane is selected based on proprietary parameters set by the plant. After sufficient cooling, these carcasses are released to the cut floor for final disassembly, with the cutting parameters varying based on the scan data collected prior to the first cut ever being made.

Traceability of each carcass on the harvest floor in the coolers and through release of the carcass onto the cut floor for final disassembly is achieved through the use of strategically located rail vision systems. Each gambrel assembly is marked with a unique identifying pattern, which is read by the vision system and used to link data metrics collected at the given location, typically the imaging data and carcass metrics previously recorded.

In addition to synchronizing data collection, the vision system provides a built-in way to trace each carcass’ path through the facility. If a given carcass fails inspection or is pulled offline from the main rail for rework, the original scanned sequences can be disrupted or reordered. As a result, it is necessary to monitor the transition “gateways” from one functional portion of the plant to the next to trace the product fully through the facility.

Magnetic metal detection and X-ray systems are used primarily at the end of line to be sure foreign matter embedded in a product doesn’t leave the facility. While contamination hasn’t been a problem in the plant, the main reason to screen all products is the possibility of foreign objects such as embedded needles that break off during injections on the farm. “A lot of our farms have already gone needleless, and we get more converting over to needleless all the time,” says Porter. “So, we’re not just mitigating the risk at the end of the line, we’re working upstream to avoid the risk in the first place.”

While the data collection system ties all areas of the plant together from an informational point of view, it’s the conveyor system that moves product from one area of the plant to another. The total conveyor length, combining kill, cut and material handling, is 16,896 linear feet, equivalent to 3.2 miles, or about the length of 47 football fields. Packaged product is transported through the conveyor network, capable of sending it to various palletizing stations depending on product, customer or destination.

Palletized product is stored in a cooler for fresh product sales or a freezer for export or longer term storage prior to shipping. A series of high airflow blast cell freezers are also available for product freezing purposes.

One detail that gets lost in all the miles of conveyance or thoroughness of the data collection system is the problem of moving some of the scraps to rendering, but doing it efficiently, without making employees unnecessarily do the legwork.

What is the solution to moving trash or trim?

“We use ‘air-blow’ technology to move some of the inedible product back to rendering,” says Porter. “We don’t truck it, forklift it or combo it. We drop it into some common collection points, and air-blow it back to rendering.”

Sustainability: Recovering value wherever practical

There are opportunities to recover value from the process in many areas—whether product related or energy related. For example, the on-site rendering facility converts organic waste (e.g., blood, bone, trim, etc.) into grease, dried blood and bone meal, which are then sold to downstream users of these materials.

Hot water at both 140°F and 180°F is required for daily wash down and sanitation processes in the plant. This hot water is generated by capturing waste heat off of the facility’s rendering system. The rendering system takes waste scrap meat trimmings and bones and renders or cooks them via a steam-driven super cooker. The liquid that is evaporated during this rendering process carries significant odors if released directly to the atmosphere. These odors are mitigated by running the vapor over a cooling coil that condenses the odorous vapor and discharges it to the wastewater treatment system. The water that runs through the cooling coil enters at around 55°F and exits at approximately 140°F. The coil is sealed and the water that enters and exits the coil remains potable. The 140°F water is stored in 100,000 gallon storage tanks to be used during the third shift sanitation process.

The ammonia refrigeration system uses heat recovery approaches for use in both defrost operations as well as under-floor permafrost heave protection under the freezer floors. The refrigeration evaporator coils throughout the facility will build up ice on the coils during normal operation, eventually restricting air flow and decreasing the cooling performance.

These coils need to be regularly defrosted to melt the ice that forms on them. There are several means of defrosting a coil, including air defrost, water defrost or hot gas defrost. The STF plant uses a hot gas defrost system, which uses waste heat from the condenser system and redirects the warm gas to the evaporator coils to provide the means of defrost.

Waste heat from the condenser systems is also used to heat glycol, which is pumped through distributed tubing underneath freezer floors. Without a means of heat under the freezer floors, the temperatures within a freezer could eventually cause the moisture in the sub-grade soil to freeze, causing potential heaving of the floor. Plate and frame heat exchangers are used to take the hot ammonia gas and transfer its heat to the closed-loop glycol system under the freezer floors.

The on-site wastewater treatment facility is used to treat the effluent water to the required environmental standards before sending it to the publicly owned treatment works, thereby eliminating surcharges. The on-site wastewater treatment system captures and recovers oils and greases through the use of dissolved air flotation, which is then also transferred to the rendering plant for value recovery.

The STF wastewater treatment facility is also equipped with four covered anaerobic lagoons, which produce as a byproduct a biogas consisting of approximately 65 percent methane gas. This gas is collected, filtered, dried and compressed, then used as a fuel for the steam boilers. The lagoons produce up to 20,000 cu.-ft. per hour of biogas, and are capable of generating up to 15,000 lbs. per hour of process steam. The use of this biogas will save up to $400,000 per year in natural gas cost and will reduce overall carbon dioxide and carbon monoxide emissions from the facility.

Porter says the wastewater treatment system is up to speed and processing more than 1 million gallons per day. The anaerobic lagoons are producing biogas as they continue to mature. “We do expect to see more gas production as the lagoons mature and as our production schedule fills out into the second shift,” says Porter.

The lagoons were designed in a manner to minimize the amount of soil import/export activities required during the earthwork portion of construction. A number of factors go into the geometry of a lagoon, including flow rate, residence time, depth vs. berm height, etc. The design of the lagoons was performed to balance the amount of soil that was excavated below grade, and balance that with the height and width of the berm surrounding each lagoon.

Making spaces compatible with employees

Enhancing the employee experience was an important part of the facility design, so STF and Epstein worked out the details. First, the office/visitor and employee entrances were given priority and were designed for a pleasant employee experience. For example, the welcoming area and bright lobby feature daylighting and a design that exudes openness, cleanliness and spaciousness.

“Designed into the building are wide hallways on the first and second floors,” says Porter. “The second floor hallways contain large viewing windows, great for visitors.”

In addition, a “T”-shaped welfare space design provides efficient employee distribution to and from work spaces and features day-lit spaces like a full-service cafeteria, numerous multimedia training rooms, and an open, clean, efficient and modern looking office space. The training rooms help STF demonstrate its corporate mission, vision and safety goals.

“We pride ourselves in providing a safe work environment for our employees, which also includes proper training during the onboarding and orientation process,” says Porter. “Technical skills are learned partially in a classroom setting and on the floor. STF has invested in a program that provides a highly efficient, engaging training process for our new hires. With this program, we have the ability to more effectively track employee training scores and classes by recording all information digitally.”

Older plants are often missing a necessity that STF enjoys in its new facility, and that’s the use of designed-in ergonomic spaces within the production areas. In a facility like this, with fast production speeds and plenty of automated equipment, safety and comfort have to be designed in, and Epstein performed well.

Ergonomic platforms were designed throughout to help with employees’ ability to safely and efficiently access work spaces, and the process floors were planned to allow for the most effective workflow based on the sound distribution of staff. In addition, all these spaces were programmed, planned and designed with the safety of workers in mind.

See more Fabulous Food Plants!

For example, the various robotic processing equipment are enclosed in protective cages to ensure the safety of STF employees working around and with these highly specialized cutting tools. In the CO2 stunning areas, the plant features numerous fail-safe alarms and sensors to prevent the accidental spread and concentration of CO2 gas from entering human occupied spaces.

Selection of high-performance materials also makes the facility last longer and require less maintenance, especially in environments with temperature swings as wide as 140°F. One high-performance material is the Margia granite floor in the cut room. “The granite flooring in our facility provides a more lasting flooring option,” says Porter. “We expect to realize a lower total cost of ownership as a result of the investment in the Margia flooring.”

Besides the flooring, stainless steel wall panels and equipment were used throughout the production spaces, precast structure was used in the production areas, hot dipped galvanized structures in the barn, wash-down LED lights in the production areas and high-performance, slip-resistant urethane flooring in high traffic areas.

Finally, in terms of acquiring staff from the local community, the new plant was able to integrate successfully 1,000 workers into the building and STF’s corporate culture in just 90 days. In the days before the Internet, this would have been a much slower and arduous task. But, today’s social media tools like Twitter, Facebook and LinkedIn were used to educate and recruit potential staff members to STF’s corporate goals, ideas and processes.

Has the community support met STF’s expectations? “Absolutely,” says Porter. “The support from local leadership, city and state officials, partners and contractors, and community members has been more than we could have imagined or expected. Our $330-million-plus investment in Seaboard Triumph Foods currently still stands as the largest development project within the city limits of Sioux City.”

.webp?t=1721343192)