LIGHTNING MVP System Keeps QA Ducks in a Row

Being responsible for quality assurance can be a bit like being pecked to death by ducks. Each individual quality program seems manageable, but when viewed as a whole they can be difficult to integrate and implement given limited staff and budget. And, when employee training is added and certification on the required instrumentation, maintaining and tracking the equipment itself, recording the test results, maintaining a clear audit trail, and finally publishing program results for management overview—it can be overwhelming at best, and ineffective at worst.

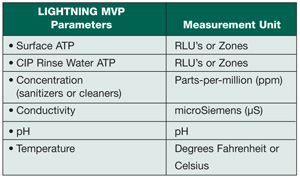

A new approach to managing these multiple programs uses a single, hand-held instrument to measure multiple quality parameters. This testing platform, offered by BioControl Systems, Inc. (www.biocontrolsys.com), is the LIGHTNING MVP® System. The LIGHTNING MVP measures and records ATP levels of surfaces or CIP (clean-in-place) rinse water systems. It also has the ability to measure and record sanitizer or cleaner concentration levels, pH, temperature, and conductivity. The test results are automatically saved on the instrument and easily uploaded into software for storage and analysis.

A plant may use one or all of these measurement capabilities depending on their needs. The base unit incorporates the ATP measurement, at a comparable price to other luminometers in the market. To add other measurement capabilities, reusable process can be purchased and simply connected to the instrument, providing a cost-effective way to expand a lab’s testing capabilities. Best yet, additional measurement capabilities can be added to the test platform at any time as a plant’s quality monitoring program changes.

Another benefit of single, multiparameter instrument is that it simplifies a number of tasks: from employee training, to instrument maintenance, even reporting. The instrument is designed to be taken on the plant floor, so samples needn’t be taken back to the lab for analysis, easing test time. Finally, all five test parameters can be calibrated on-site so shipping instruments to manufacturers is not required.

Accuracy is fundamental to the LIGHTNING MVP in each of its measurement parameters. With its calibration capabilities the system adheres to GMP and HACCP principles, but it also allows for calibration validation and positive controls, assuring accurate results. The instrument is designed to be taken on the plant floor as consideration for things such as temperature variation, vibration, and humidity—which can affect results—is built into its rugged design.

Regardless of which critical control points are measured, the value of a multiparameter test platform is evident. A company’s monitoring needs will change, and the LIGHTNING MVP is the only system that will evolve with those needs.

Concentration is Key

Not only can a multiparameter monitoring tool like the LIGHTNING MVP increase a plant’s efficiency, it can also save money through one of its measurement parameters, the ability to measure sanitizer and cleaner concentration. Using sanitizing and cleaning chemicals at the correct concentration is vital to their efficacy. Regardless of how well trained an employee is, traditional measurement technologies for chemical concentration have drawbacks that affect accuracy. This inaccuracy can create a food safety issue when the solution is too dilute and a cost containment issue when over-concentrated.

Titration kits and test strips require subjective interpretation of a color change and therefore are accurate to approximately ±25%—which leaves dangerously large margin for error. Under-mixing solutions will cause the cleaning or sanitizing solution to be ineffective. Conversely, over-concentrated solutions waste chemicals. With sanitizing and cleaning chemicals being such a large budget item, over-use of even 10% amounts to a significant—and unnecessary—expense.

The method available with the LIGHTNING MVP system utilizes conductivity to ascertain solution strength. Because conductivity increases in a linear fashion as concentration increases, the method can be used to derive highly accurate concentration measurements. To measure using this method, a reusable electronic probe is calibrated by reading both an “ideal” sanitizer or cleaning mixture and the water used to dilute the concentrate, establishing a baseline. Subsequent chemical solutions are then compared to this baseline and readings reported in parts-per-million. The concentration readings taken by this method are accurate to ±5%, a significant improvement over the accuracy of strips or titration kits.

The LIGHTNING MVP is a unique way to approach the multiple tasks and programs that quality assurance and sanitation professionals must manage. By offering an expandable platform, a company can avoid investing in multiple instruments or struggling to consolidate results for reporting. This consolidation of test methods mirrors the consolidation of monitoring programs that QA and sanitation managers must achieve every day and provides maximum utility and value to a quality assurance program. Maybe it can even save you from a duck or two.

biocontrolsys.com >

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →