Developing and Assessing GAPs Programs in Preparation for the Food Safety Modernization Act

Pathogens from a variety of sources (e.g., water, manure, soil, animals and humans) can contaminate produce. Contamination events can occur at several points from farm to table, during growing, harvesting, packing and processing, transportation and food preparation. Outbreaks associated with produce have increased over the past 30 years, and the outcome is emphasis on produce food safety practices. A key to fresh produce food safety is emphasis on practices to reduce risk at each point in the food chain. Limiting pathogen introduction at the farm level is a critical contribution to the safety of the final product.

Good Agricultural Practices (GAPs) comprise a prerequisite program that can be utilized to manage food safety risks in the field and as produce transitions from the field to packing environments. Several third-party certification programs are available and are utilized to examine food safety GAPs on farming operations. Many produce-growing and packing operations have designed food safety management programs to meet third-party certification standards and buyer requirements. The Food Safety Modernization Act (FSMA) will significantly affect the formal food safety regulation of fresh produce. The U.S. Food and Drug Administration (FDA) conducted meetings in several states to gain input from growers and other interested groups. A proposed rule that will be open for public comment is anticipated in the spring of 2012. Produce growers and packers wonder if regulatory requirements will align with current expectations and practices. Since 1998, the FDA has provided guidance documents for general produce products and specific commodities that can be examined. Preliminary indications suggest that FSMA produce regulations will be congruent with currently available guidance documents. Although exact verbiage for the implementation of FSMA is not yet available, produce growers and packers can prepare now for future regulatory outcomes. Table 1 outlines specific areas mentioned in FSMA that can be strengthened in anticipation of future rules.

Produce-growing and packing operations will see increased regulatory expectations regarding documentation of food safety practices. Producers and packers of raw agricultural products would benefit from examining the topics addressed in Table 1, identifying strengths and areas to improve prior to release of the regulation. Examining these operational practices in the coming months can ease the transition to FSMA regulations. To successfully strengthen the outlined areas, important preliminary steps must be in place to ensure that these activities are successful. Effective food safety programs are built through management commitment and sufficient food safety knowledge among employees within an operation. Therefore, this article focuses on preliminary steps and employee training to support a GAPs program. These activities are critical as operations move forward to assess preventive control plans and evaluate traceability and documentation practices.

Assess Management Support

Management support is a key factor to ensure the success of any food safety program. Making changes in an operation to ensure regulatory compliance will likely require additional time and resources. Food safety and quality personnel can engage and communicate with management to develop strategies for assessment of current GAPs. Operations that do not have personnel trained in food safety and GAPs should invest in training. Working together with management in the coming months can develop a foundation for food safety and alignment with new regulatory requirements.

Cultivate an Active Food Safety Team

Food safety team members can contribute to assessment of preventive control plans, traceability and documentation practices. Designate a team leader for a GAPs program, but recognize that no single individual has complete knowledge of all activities within a given operation. Having sufficient staff with food safety knowledge to support a GAPs program is important. Training key personnel to understand and recognize potential food safety risks will assist the operation in identifying and controlling risk factors appropriately. Input from different perspectives in the operation ensures that numerous factors that can influence food safety are considered.

Every individual in an operation can affect food safety; therefore, a network of employees with food safety knowledge benefits the operation. By involving several employees, it is also more likely that information about GAPs will be communicated throughout the operation and increase support for food safety. Furthermore, vigilant evaluation of daily practices for food safety risks is more likely when multiple people are involved.

Experiences with GAPs Training in the Northwest

The importance of investing in food safety training for key operational personnel at the grower level is critical for GAPs implementation. Numerous programs deliver GAPs education and training to produce growers and packers throughout the U.S. The following sections discuss a GAPs educational program offered in the Northwest and strategies that assisted growers with implementation of GAPs. The Washington State University (WSU) GAPs team was formed in 2007 and has delivered workshops to over 700 producers. Program evaluation, including a 1-year follow-up, has been completed for participants from November 2008 through March 2010.

The GAPs workshops were presented by an experienced, multidisciplinary team, including several WSU departmental faculty from the School of Food Science and Crop and Soil Sciences as well as county-based faculty. Several project partners (e.g., producer groups, state agencies, produce distributors and farmers market organizations) were involved in program promotion and planning. The program was developed as a two-workshop series. Session I focused on increasing knowledge about food safety and GAPs. Topics included produce food safety and pathogen risk, irrigation water quality, manure management and composting, worker health and hygiene, as well as sanitation during harvest, storage and transportation.

Representatives from the Washington State Department of Agriculture and Department of Health Food Safety Programs also discussed regulatory perspectives and topics important for growers who direct-market produce. Session II was delivered 2 to 4 months after Session I and focused on implementation of GAPs in participants’ operations. Session II utilized a discussion-based format with WSU faculty serving as moderators and resources. A discussion guide was available, but emphasis was placed on producers identifying topics and asking questions. To date, 13 Session I workshops and 10 Session II workshops have been delivered, and the program is ongoing.

From 2008 to 2010, growers with a broad range of experience, acreage and specialty crops attended programs. Although the target audience was producers who direct-market produce, about 25 percent of participants represented large-scale commercial operations. Both inexperienced (less than 5 years) and experienced (more than 20 years) growers attended the workshops.

WSU GAPs Program Evaluation and Impacts

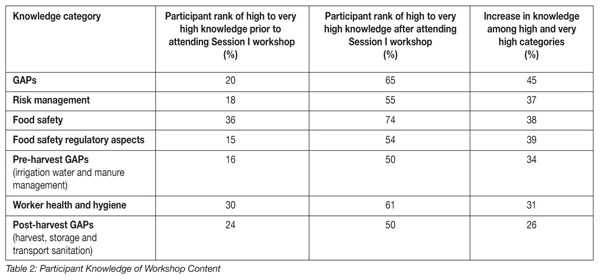

Session I documented increased knowledge among participants. Evaluations were conducted at the end of the workshop, and a retrospective pre-/post-workshop questionnaire was used to measure knowledge. Participants were asked to rank their knowledge of specific topics prior to the workshop and after the workshop using a five-point scale: very low, low, moderate, high and very high. Responses were assessed for increases in the ranking of high and very high categories. Session I documented increased knowledge among participants (Table 2). After Session I, the largest knowledge increase (45 percent) was observed for overall GAPs. Knowledge of food safety, regulatory aspects and risk management increased more than 35 percent. The largest increase in knowledge of specific GAPs was pre-harvest topics (e.g., irrigation water quality and manure management), with a 34 percent increase, followed by worker health and hygiene and post-harvest topics.

Producers reported implementation of GAPs in their operations after participation in the WSU workshops. From 2008 to 2010, 161 producers completed the GAPs program by attending Sessions I and II. At Session II, more than half (58 percent) of participants made progress on GAPs implementation since Session I. Additionally, 53 percent of participants reported progress on GAPs record keeping, and 31 percent reported progress toward third-party certification. Producers had 2 to 4 months to assess their operations for GAPs between Sessions I and II. A challenge associated with this practice was that fewer producers returned for Session II (i.e., 161 of 483 Session I participants). A positive aspect was that producers could utilize their increased knowledge of food safety and GAPs to evaluate their operations and develop specific questions for Session II based on their practices. Based on the interactive discussions during Session II and documented progress on GAPs implementation between sessions, the program format appeared to encourage progress on GAPs among producers.

It is also important to note that program impacts could not be completely captured due to reduced response rates among participants. Feedback from producers who attended only Session I indicated that several implemented additional GAPs, although they did not attend Session II. Similarly, in follow-up evaluations of both Session I and II participants, 76 completed an online evaluation. Results indicated that program impacts were achieved, with producers implementing GAPs after program completion.

Progress on general and specific GAPs implementation was assessed at Session II and in the follow-up evaluations. Figure 1 examines general practices that participants said they were performing prior to program participation, as well as practices implemented after program participation and practices that producers planned to implement in the future. After program completion, one-quarter of respondents reported additional progress on record keeping and adoption of an overall GAPs program. Some participants (8 percent) achieved third-party GAPs certification after program participation, and 16 percent were already third-party certified. In follow-up evaluations, 33 percent intended to adopt an overall GAPs program and 29 percent intended to achieve third-party certification in the future. Furthermore, almost all participants indicated that they had discussed information from the GAPs program with others. After program participation, two-thirds (67 percent) of respondents reported discussing information from the GAPs workshops with one to nine people. Additionally, 16 percent discussed information with 10 to 24 people, and 12 percent discussed information with 25 to more than 100 people. On-farm employee training represented some of the reported communication about GAPs.

An important result of program participation was the adoption of on-farm food safety training. Almost one-third (32 percent) of respondents reported adopting employee food safety training after program participation (Figure 1). Producers recognized the importance of increasing awareness of food safety risks and emphasizing why GAPs were needed in the operation. Employee training likely assisted with GAPs implementation in these operations.

Trends were observed among frequencies of producers adopting specific GAPs (Figure 2). In the Session II evaluation, open-ended questions were utilized for participants to indicate GAPs that were being performed prior to attending the workshops as well as practices that they intended to implement. To gather more specific information in the follow-up evaluations, responses to the open-ended Session II question were developed into response categories provided in the follow-up evaluation. At Session II, the most frequent practices addressed prior to the workshops were hygiene and sanitation. However, these areas were also a frequent focus after workshop participation. After completing the workshops, hygiene facility monitoring and worker health and hygiene training were adopted by 33 percent and 29 percent of respondents, respectively. Almost 25 percent of respondents adopted additional harvest and storage sanitation practices after program participation. Areas where the frequency of adoption was lower, perhaps indicating areas where producers need additional assistance and education, were irrigation water testing, manure management and composting practices. During the workshops, producers indicated that the topics of irrigation water and manure management practices were challenging due to differences in recommendations, testing methodologies and currently available scientific information.

In the follow-up evaluations, participants were asked to describe factors that motivated GAPs implementation as well as challenges to implementation. The primary motivator identified by 30 percent of the participants was buyer requirements; other motivators included product liability, product safety and the potential that GAPs may become mandatory in the future. Factors that made GAPs adoption challenging were paperwork, cost, new habits, lack of employee understanding of expectations and lack of practical implementation information. The evaluated workshops were conducted prior to development of the FSMA. Some producers recognized the potential for future regulations related to on-farm produce food safety. However, buyer requirements were the driving factor for GAPs implementation and influenced program attendance from 2008 to 2010.

The WSU GAPs program continues to deliver workshops, and evaluation of the program is ongoing. The initial assessment indicated that participant knowledge of GAPs and food safety increased because of participation. Program impacts were documented at Session II and in follow-up evaluations. Producers implemented additional GAPs and record keeping after program participation. Third-party GAPs certification status also changed for some producers. Through delivery of the workshops, the team found certain strategies useful in conducting the training. These strategies contributed to positive experiences for the producers and assisted with GAPs implementation. Producer comments in evaluations and feedback during workshops guided the following observations.

Discuss the Science Behind GAPs

It is important to address topics of pathogen risk associated with produce, basic principles of food microbiology and foodborne illness. This information should provide sufficient background so that producers understand potential sources of pathogens and routes of produce contamination. Moreover, giving producers a sense of the burden of foodborne illness in the U.S., susceptible populations and epidemiological investigations during outbreaks provides context for the need to implement GAPs. Many producer comments indicated that understanding the science behind GAPs was valuable. Producers mentioned that providing information on foodborne illness and produce outbreaks emphasized the importance of protecting their customers and why it is essential to reduce pathogen risk at the farm level.

Understanding the science increased commitment to adopting GAPs principles. Producers mentioned that providing information beyond how to meet certain certification standards was beneficial. Farmworkers who understand pathogen sources can identify practices that increase the risk of contamination and practices that promote pathogen growth. This foundation of food safety knowledge can lead to identification of alternative practices to reduce risk.

Make Pathogen Risk “Real,” Not Scary

Conveying the reality of low levels of microscopic foodborne pathogens in farming environments can be challenging. A useful approach is to discuss differences between typical food spoilage microorganisms and foodborne pathogens. Illustrate that spoilage microorganisms ultimately leave indicators of their presence: off-odors, colors and flavors. However, contaminated foods often look safe to eat. Pathogens are difficult to detect yet threaten the health of customers and the operation. Emphasis on preventing pathogen introduction is important because pathogens are not easily eliminated once present on fresh produce. Giving participants an appreciation that pathogens are complex organisms with unique survival strategies provides context for GAPs.

To assist with these concepts, the lecture on pathogens and produce featured an E. coli Giant Microbe (a rod-shaped plush doll). This training tool was well received by participants and assisted in visualizing pathogens. It was also used if participants had questions about the meaning of O157 and H7 antigens. Pathogen risk can be an overwhelming topic for producers. Although it is a serious topic, using training tools and strategies to make the training fun and enjoyable for participants is important. Several participants shared that they incorporated these tools into their own employee training programs.

Engage the Audience and Be Flexible

Encourage active learning and emphasize discussion during training sessions. Several lectures during Session I workshops evolved into a discussion-based format based on participant questions. Evaluations mentioned that presentations were delivered in a way that created an atmosphere that allowed participants to feel secure and comfortable with the information presented and with the speakers. Providing participants with a voice in the educational process enhanced participant interest and encouraged a positive environment for group discussions. Active discussions increase participant confidence with the topics and may influence dissemination of information within their operations.

Share Challenges and Solutions

Program participants valued learning from each other. However, the format for sharing information was important to consider. Many local and regional producers were reluctant to serve as speakers or panelists on GAPs implementation during Session I workshops, a more formal lecture-style format. Session II workshops were discussion-based and attended by smaller numbers of participants (4–32 people per session). The interactive format of Session II allowed participants to highlight their experiences and share information with other producers in a less formal environment. Producers sharing specific practices and successful strategies for GAPs implementation was important. Additionally, sharing challenges associated with GAPs implementation provided opportunities for problem solving among participants and trainers. Producers appreciated knowing that others shared similar experiences and found feedback from other producers encouraging.

Train Key Personnel to Serve as Food Safety Resources

Identify your key employees and invest in food safety training for them. Results indicated that individuals with food safety knowledge will communicate with others in the operation about food safety issues. Establishing a network of communication about food safety within an operation is likely to enhance success of GAPs implementation.

Moving Forward

In the coming months, opportunities exist to make progress on GAPs programs and the factors emphasized by the FDA for upcoming FSMA regulations. Enhance food safety infrastructure within your operation: management commitment, food safety teams and employee training. Investing in employee training to increase food safety knowledge will enhance support for evaluating food safety programs and increase food safety awareness throughout the operation. Effective food safety programs, like GAPs, are developed, implemented, reassessed and adjusted regularly. These are not static programs. Assessing your current operational practices and food safety programs now and strengthening areas related to risk assessment and preventive control plans, traceability and documentation in the future will be time well spent prior to release of the initial FSMA rule related to produce.

Karen Killinger, Ph.D., is an assistant professor at Washington State University (WSU) in the School of Food Science, Pullman WA. Her extension and research program spans the farm-to-table continuum. At the farm level, her program examines the prevalence of foodborne pathogens in agricultural environments and the WSU GAPs team provides GAPs educational programs. Dr. Killinger’s program also performs validation studies for packing and processing interventions. Consumer educational programs focus on promoting the use of meat thermometers. She can be reached at karen_killinger@wsu.edu.

Acknowledgements

WSU GAPs program material is based upon work supported by USDA National Institute of Food and Agriculture award 2010-49200-06203.

Funding for this project was provided by the WSU Western Center for Risk Management Education and the USDA National Institute of Food and Agriculture. Team members Andy Bary, Craig Cogger and Richard Dougherty, along with the contributions of Claudia Coles, B. Susie Craig, David Gifford, Joe Harrison, Carol Miles and Marcy Ostrom, are greatly appreciated.

Resources

1. Ayers, T.L. 2006. Outbreaks of E. coli O157 infections associated with lettuce and other leafy greens. Presented at E. coli O157:H7 in lettuce and leafy greens: Strategies for developing an intervention assessment model. November 13–15.

2. Beuchat, L.R. and J.H. Ryu. 1997. Produce handling and processing practices. Emer Infect Dis 3(4):459–465.

3. Beuchat, L.R. 1999. Survival of enterohemorrhagic Escherichia coli O157:H7 in bovine feces applied to lettuce and the effectiveness of chlorinated waters as a disinfectant. J Food Prot 62:845–849.

4. www.fda.gov/Food/GuidanceComplianceRegulatoryInformation/GuidanceDocuments/ProduceandPlanProducts/default.htm.

5. www.fda.gov/ForConsumers/ConsumerUpdates/ucm262031.htm#3.

6. Islam, M., J. Morgan, M.P. Doyle, S.C. Phatak, P. Millner and X. Jiang. 2004. Fate of Salmonella enterica serovar Typhimurium on carrots and radishes grown in fields treated with contaminated composts or irrigation water. App Env Micro 70:2497–2502.

7. Islam, M., J. Morgan, M.P. Doyle, S.C. Phatak, P. Millner and X. Jiang. 2004. Persistence of Salmonella enterica serovar Typhimurium on lettuce and parsley and in soils on which they were grown in fields treated with contaminated manure composts or irrigation water. Foodborne Path Dis 1:27–35.

8. www.agrisk.umn.edu/verification/vrregister.dll/ publicresults?ProjectNumber=RME-D8H02605.

9. Rangel, J.M., P.H. Sparling, C. Crowe, P.M. Griffin and D.L. Swerdlow. 2002. Epidemiology of Escherichia coli O157:H7 outbreaks, United States, 1982–2002. Emerg Infect Dis 11:603–609.

10. producesafetyalliance.cornell.edu/2011% 20PSA%20Proceedings.pdf.

11. Sivapalasingam, S., C.R. Friedman, L. Cohen and R.V. Tauxe. 2004. Fresh produce: A growing cause of outbreaks of foodborne illness in the United States, 1973 through 1997. J Food Prot 67:2342–2353. >

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →