Microwave-Assisted FAMEs Analysis

The determination of accurate fatty acid profiles in food is becoming critical in food production, as consumers and regulatory agencies demand more complete information on the foods we eat. Although the United States has required the labeling of total fat, trans fat and saturated fat for years, the regulations are expanding. The European Union (EU) has already increased testing requirements with the passage of regulation 1169/2011, which states that saturated, monounsaturated and polyunsaturated content must be displayed on all packaging in the EU as of December 2014. The additional regulation poses a challenge to a process that currently uses low-throughput methodology and long conventional methods usually performed by independent laboratories. Fortunately, a microwave method has been developed to increase the throughput, shorten test time and remove hazardous reagents.

There are many procedures to determine fatty acid content in food, based on the different food matrices to be analyzed (dairy, meat, prepared foods, etc.). In general terms, fatty acid profiles are determined by converting the fatty acid into its fatty acid methyl ester (FAME), which is then analyzed and quantified using gas chromatography (GC). The percentage of each FAME is determined by the corresponding peak area of the chromatogram. This can then be used to calculate the actual amount of each fatty acid based on the total fat in the sample.

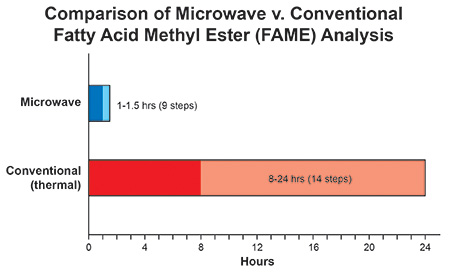

In the laborious, conventional method, a solvent extraction is used to determine total fat in a food matrix. The esterified fatty acid goes through saponification to convert it into a free fatty acid, typically using heat and a strong alkali (e.g., potassium hydroxide). The free fatty acid is then re-esterified to form the methyl ester, which generally requires a toxic catalyst such as boron trifluoride. The resulting FAMEs must be extracted with an organic solvent and dried before analysis by GC. The entire process can take 8–24 hours and 12 to 18 steps to complete, depending on the sample.

In contrast, microwave preparation of FAMEs simplifies and makes the procedure significantly safer by eliminating the need for harsh reagents. The one-pot methodology is robust enough to use the same procedure for a variety of complex food matrices, including meat, dairy and prepared meals. The simplicity of the microwave procedure begins by replacing the initial solvent extraction step with total fat analysis using a SMART Trac II System, which incorporates both microwave drying and second-generation nuclear magnetic resonance technology. The system utilizes AOAC methods for meat and dairy products, quickly and easily determining the total fat in minutes without solvents. After the total fat is determined, the rest of the procedure is carried out in a microwave sample preparation system. Saponification is performed, followed by the generation of the FAMEs using only a methanolic hydrochloric acid solution. As with the conventional process, the resulting FAMEs are extracted, dried and analyzed using GC. Using the MARS 6 Microwave Sample Preparation System, up to 40 samples can be ready for GC analysis in as little as 1 to 1.5 hours. Additionally, as the system utilizes specially designed closed vessels, it ensures there is no loss of volatile compounds, such as butyric acid from dairy samples, and eliminates the use of breakable lab glassware.

Compared to conventional results, the microwave method yields comparable or better conversion and recovery of the FAMEs, including levels of short-chain fatty acids, despite the higher temperatures involved in the microwave procedure. The microwave method enables complete recovery of long-chain fatty acids and encapsulated omega-3-fortified fatty acids that are not recovered by AOAC methods. Since conventional procedures are gravimetric, the fat extracted in the first step of the process consists only of free fatty acids. In the microwave method, however, the whole sample, not just the extracted fat, is saponified, resulting in the complete extraction of both bound and free fatty acids.

The use of microwave methodology to shorten test time, reduce hazardous reagents and increase throughput has significantly improved FAME analysis. The procedure is comparable or better than the conventional process in both recovery and reproducibility, with the added benefit of offering a universal method for multiple sample types. Using the MARS 6, up to 40 samples can be prepared in less than 2 hours compared to up to 24 hours using the conventional method. In addition, the system offers a 4-fold reduction in solvent costs and does not require the use of a fume hood. The speed and simplicity of the methodology decreases the potential for human error and gives manufacturing laboratories easy access to a procedure that they will need to use with increasing frequency.

www.cem.com >

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →