Utilization of Steam Heat Generated via Microwave Energy

The purpose of this study was to evaluate the effectiveness of steam-heat processing of food within a covered Cambro pan containing water with energy generated via microwaves. Specifically, the study was designed to determine adequate heat transfer and time/temperature cooking parameters for seafood products.

Background

Most restaurants and retail food stores rely upon traditional steamers to cook seafood products to the required temperature of 145 °F as specified within the U.S. Food and Drug Administration (FDA) Food Code.[1] The problems associated with conventional steamers include the high costs of the units, energy expenses and complicated plumbing hookups. The difficulty of cleaning and sanitizing the interior area of conventional steamers is of particular concern. A solution to these issues is the use of microwave-generated energy to steam-cook seafood products within covered Cambro pans containing water.[2–4] First, the microwave units are portable and don’t require expensive and complicated steam and wastewater plumbing hookups. Second, the Cambro pans are available in different sizes to economically accommodate the volume of food items being prepared. Third, the stainless steel microwave units as well as the Cambro pans are easily cleaned and sanitized. Fourth, cooking time is reduced significantly in that a traditional 1.5-pound lobster can be steamed to a minimal internal temperature of 145 °F in a total of 4 minutes (2 minutes cooking and 2 minutes holding). Fifth, there is a large savings in energy costs using microwaves to generate steam as opposed to using conventional steamers.

Section 3-401.12 of the 2009 edition of the FDA Food Code1 requires that raw animal foods, including seafood, heated via microwave energy must attain an internal temperature of at least 165 °F. However, traditional steam heating of seafood products need only attain an internal temperature of 145 °F. This study was designed to determine whether cooking seafood in covered Cambro pans with added water and using microwaves as the energy source to produce steam was equivalent to cooking seafood in traditional-style steamers. If this premise is proven true, then it could suggest that the Food Code be amended to allow for the steam heating of seafood products to a minimum internal temperature of 145 °F using microwave energy as the source.

Objectives

The four major objectives of this research were the following: (a) compare the cooking of seafood using traditional microwave energy for heat transfer versus using microwave-generated steam within covered Cambro pans; (b) determine time/temperature cooking parameters for heat transfer using microwave-generated steam within a covered Cambro pan; (c) determine temperature variations within various seafood products processed using microwave-generated steam within a covered Cambro pan and (d) ultimately, determine the equivalency of heat transfer within seafood utilizing steam generated via microwave energy within a covered Cambro pan compared with traditional seafood steamers.

Materials

A Panasonic 3200-watt 4-magnetron “Sonic Steamer” microwave was used as the energy source for creating microwave-generated steam.[2] The 12-inch-by-20-inch-by-4-inch pans used were Cambro microwave steaming trays with covers, composed of high-density polyethylene. Lobsters weighing 1.5 pounds each and 23.2 ounces of jumbo shrimp (12/25 count) were used as the shellfish typically steamed by traditional methods. Water was added as a catalyst to create steam. A Fluke model 189 True RMS Multimeter thermocouple using an 80B-A Integrated DMN temperature probe was used to monitor internal food product and steam temperatures.

Procedures

Both lobster and shrimp were processed within the microwave oven in a covered Cambro pan at high power and allowed to stand for 2 minutes after cooking to obtain temperature equilibrium. When water was added, a ratio of 30 ml per pound of lobster or shrimp was utilized. Internal temperatures of the lobsters were taken at five locations at approximate 1-inch intervals from the head to the tail; the temperatures of each claw were also taken. The internal temperatures of the shrimp were taken at the large headless end only. The five experiments conducted were: (1) 45 ml water only in a covered Cambro pan; (2) one 1.5-pound lobster in a covered Cambro pan with 45 ml water; (3) one 1.5-pound lobster in an uncovered Cambro pan with 45 ml water; (4) one 1.5-pound lobster in an uncovered Cambro pan with no water added and (5) 23.2 ounces of large shrimp in a covered Cambro pan with 45 ml water.

Results

The results of the five experiments were as follows:

1. The temperature of the steam environment in the covered Cambro pan that contained water only was 191 °F after 2 minutes at high power.

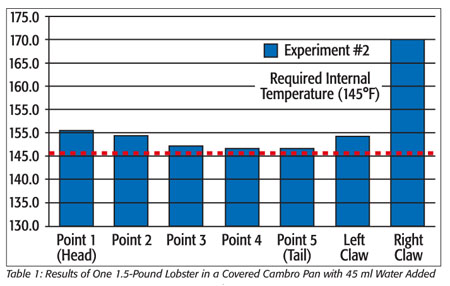

2. The 1.5-pound lobster in a covered Cambro pan with 45 ml water added, after 2 minutes at high power followed by 2 minutes of standing time, exhibited internal temperature readings at the five locations from head to tail and left and right claws of the lobster as shown in Table 1. The standard deviation was calculated as 1.799. The temperatures of both the right and left claws were 170.0 °F and 149.3 °F, respectively.

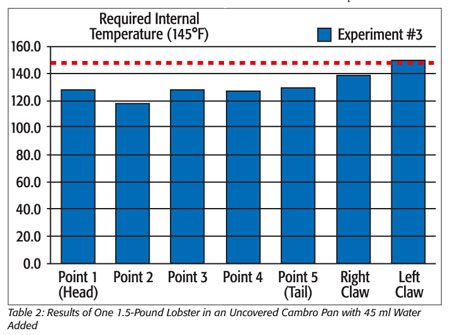

3. In a comparison of a covered Cambro pan with an uncovered Cambro pan, a 1.5-pound lobster was placed in an uncovered Cambro pan with 45 ml water added. After 2 minutes at high power followed by 2 minutes of standing time, the internal temperature readings at five locations from head to tail and left and right claws of the lobster are shown in Table 2. The standard deviation was calculated as 4.347. Additionally, the temperatures of both the right and left claws were 138.8 °F and 149.9 °F, respectively.

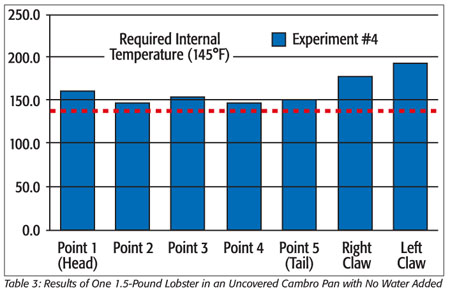

4. In an effort to show that the steam was being generated from the water, a 1.5-pound lobster was placed in an uncovered Cambro pan with no water added. After 2 minutes at high power followed by 2 minutes of standing time, the internal temperatures were taken at five locations from head to tail and left and right claws of the lobster. The results are presented in Table 3. The standard deviation was 5.413. The temperatures of the right and left claws were 176.1 °F and 194.7 °F, respectively.

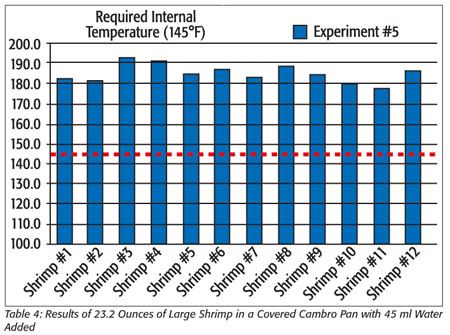

5. In the last experiment, 23.2 ounces of shrimp were placed in a covered Cambro pan with 45 ml water. After 2 minutes at high power followed by 2 minutes of standing time, the internal temperatures were taken on 12 shrimp at the larger headless end. The results are presented in Table 4. The standard deviation was 4.371.

Discussion

This study was conducted to compare heat transfer within seafood products via microwave-generated steam in covered Cambro pans with added water placed within a Panasonic “Sonic Steamer” 3200-watt 4-magnetron microwave unit with the heat transfer within a conventional steamer.[2, 3]

The first part of the study was to determine the temperature of the steam environment within the covered Cambro pan with the addition of 45 ml water only. The results indicate that the temperature within the steam-filled pan was 191 °F after 2 minutes at high power and 2 minutes of holding time. This showed that microwave energy can effectively and consistently be utilized to generate steam within the covered Cambro pan.

The second part of the study showed that lobsters placed in covered Cambro pans with 45 ml water, steamed for 2 minutes and held for 2 minutes, reached above the required internal temperatures of 145 °F. Additionally, the temperatures taken from various parts of the lobster were very close, within a standard deviation of 1.799 (Table 1), indicating an evenness of heating via steam energy. Furthermore, the combination of the covered Cambro pan with the added water along with the microwave energy generated a “steam environment” similar to conventional steamers.

In an attempt to demonstrate that the evenness of heating was related to the steam-generated heat transfer within the covered Cambro pan with water, the experiment was repeated under the same conditions except the Cambro pan was left uncovered.[3, 4] The results indicated an expected unevenness of heating from the traditional microwave energy. Steam could not be generated as in the covered Cambro pan. The temperatures were below the required 145 °F for steam heating and the standard deviation was 4.347 (Table 2), indicating unevenness of heat transfer in the lobster. This proves that the heat energy was being provided by the microwaves not the steam.

The fourth part of the study was similar to the previous two except the lobster was placed in an uncovered Cambro pan with no added water. This experiment would prove or not that the covered Cambro pan along with the water is required for even steam-heat generation. The temperatures did reach the required 145 °F for cooking but were not consistent throughout the lobster. The standard deviation was 5.413 (Table 3). This indicated that the added water is necessary for the development of steam and the heat was generated unevenly via traditional microwave energy.[4]

The final experiment included the use of large shrimp cooked in a covered Cambro pan with water added using microwave energy. Again, the product was steamed for 2 minutes and held for 2 minutes. Temperatures ranged from 176 °F to 193 °F, well above the required 145 °F internal product temperature. The standard deviation was 4.371 (Table 4) or well within the average variation of traditional steamed-cooked shrimp. Additionally, the evenness of heating was quite evident.

In all experiments, the sensory quality of the seafood in the covered Cambro pan with water and microwave-generated energy was excellent. The appearance, texture, color, flavor and overall eating quality were equivalent or better than traditional steam cooking.

There are many advantages to using microwave energy to generate steam in covered Cambro pans.[3, 4] First, the microwave units are portable and don’t require expensive and complicated steam and wastewater plumbing hookups. Second, the pans are available in different sizes to economically accommodate the volume of food items being prepared. Third, the stainless steel microwave units as well as the Cambro pans are easily cleaned and sanitized. Fourth, cooking time is reduced significantly in that a traditional 1.5-pound lobster can be steamed to a minimal internal temperature of 145 °F in a total of 4 minutes (2 minutes cooking and 2 minutes holding). Fifth, there is a large savings in energy costs using microwaves to generate steam as opposed to using conventional steamers.

Section 3-401.12 of the 2009 edition of the FDA Food Code requires that raw animal foods, including seafood, heated via microwave energy must attain an internal temperature of at least 165 °F.[1] However, traditional steam heating of seafood products need only attain an internal temperature of 145 °F. This study has shown that cooking seafood in covered Cambro pans with added water and using microwaves as the energy source to produce steam is equivalent to cooking seafood in conventional steamers. In keeping with the scientific evidence, the next logical step is to petition FDA for an amendment within the Food Code to allow for the steam heating of seafood products to a minimum internal temperature of 145 °F using microwave energy as the source.

John J. Specchio, Ph.D., is a professor of food science at Montclair State University, Montclair, NJ, and principal in Regtech LLC, a consulting company specializing in food safety and regulations.

John P. Schrade is a retired FDA regional state programs director and principal in Regtech LLC.

Mandy Unanski is a graduate student in nutrition and food science at Montclair State University.

2. www.panasonic.com/business/commercial-food-services/includes/pdf/2010-Sonic-Steamer-Ad-insert.pdf.

3. Jean, B. R. 2007. A microwave sensor for steam quality. IEEE Trans Instrum Meas 5:113–125.

4. Pingkuan D., D.P.Y. Chang and H. A. Dwyer. 2000. Heat and mass transfer during microwave steam treatment of contaminated soils. J Environ Eng 126(12):1108–1115.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →