Dorner's responsiveness helps deliver 2200 Series Conveyor for manufacturing of N95 respirators

As the COVID-19 pandemic continues causing major disruptions throughout the packaging industry on levels never seen before, Dorner is meeting these challenges head on by leveraging its expertise and expediting its conveyor systems to critical applications.

Husco is one of those applications.

Waukesha, Wisconsin-based Husco, a privately-held company specializing in high performance hydraulic and electro-mechanical components, shifted part of its production to manufacturing N95 respirators to be used by healthcare professionals and first responders to help prevent the spread of infection or illness. Husco is also part of a consortium called MaskForce (https://www.maskforce1.com/), a group representing all facets of Southeastern Wisconsin businesses to design, develop and produce the reusable face mask.

“It was a priority for us to help those on the front lines get the PPE they need do safely do their job,” said Brian Cull, director of advanced manufacturing engineering at Husco. “Being able to bring solutions that directly impact peoples’ lives is inspiring.”

For Husco to begin the manufacturing process, it needed a conveyor to move completed N95 respirators to a bagger for packaging. Working closely with Dorner and Crane Production Systems, a Waukesha-based material handling distributor, Husco was able to specify and receive a 2200 Series conveyor on the same day.

“Husco deserves to be commended for their drive in supporting COVID-19 relief efforts through manufacturing N95 masks,” said Matt Jones, vice president of sales & aftermarket for Dorner. “All the organizations that are part of the MaskForce consortium really stepped up when the area needed them, and we were happy to play a small part in making their visions a reality.”

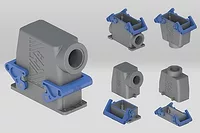

Dorner was able to supply Husco with a 10-foot long, 6-inch wide 2200 Series, a versatile platform engineered for numerous applications and industries, including accumulation, small-part transfers, inclines and declines, automated and manual assembly, packaging and industrial. As a final step prior to packaging, N95 respirators are applied with disinfectant. The conveyor moves the respirators underneath an air knife to ensure they’re dried and to perform a final cleaning. Masks then travel to a bagger, where they are packaged and ready for shipping.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Crane and Dorner worked together on Friday, April 3, to identify the right conveyor for Husco. When the conveyor was ready later that day, Cull drove to Dorner and it was prepped and loaded by his two uncles, Steve and Ken, who also work at Dorner.

“We have had a number of COVID-19 related inquires, and we’ve been very responsive to those customers who need a conveyor system right away…and in Husco’s case, that same day,” Jones said. “Everyone here at Dorner has worked well together to build and expedite orders for these time-sensitive requests.”

“The manufacturing of these N95 masks has been a top priority for Husco, and Dorner has done a really good job at prioritizing those requests,” said Dan Buretta, Material Handling Equipment Sales at Crane Production Systems. “It’s all about helping people, and I’m happy to be part of the solution for Husco.”

Made of medical grade silicone and polypropylene, the N95 respirator is a soft, comfortable mask that provides a low-pressure facial seal. The mask can be sanitized and re-used. The line at Husco produces about 3,000 N95 respirators a day.

Cull said this project, along with all the organizations that comprise MaskForce, is a great example of what companies can accomplish when they collectively ban together.

“The project as a whole really demonstrated how the greater Milwaukee area came together, collaborated and put together solutions to get help to the field quickly,” he said. “These businesses all got together and said, ‘What do we need to do?’ It was really inspiring and rewarding to work in that environment.”