Technologies for scheduling preventative maintenance

It's 2019, and many companies are ditching pen and paper and turning to software for their equipment and facility sanitation, as well as maintenance.

There are many benefits of using software vs. paper to schedule equipment and facility sanitation and/or maintenance, says Robert Burgh, president, Nexcor Food Safety Technologies, Atlanta.

"Using software for sanitation and maintenance scheduling increases efficiency by having all documentation in one place. Managers can more easily check past work, review tasks, and have all audit documentation accessible without searching through binders or having information embedded within different departments," he says.

Management can alter scheduling and better allocate resources based on trended data within electronic systems. Cohesive data that is easily accessible and easily analyzed fundamentally helps facilities remain compliant and continuously improve, Burgh states.

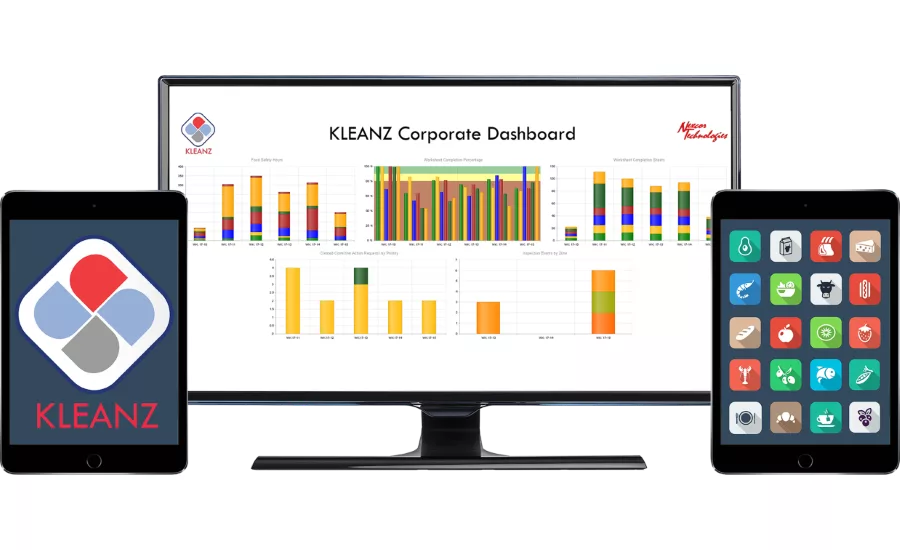

Nexcor's KLEANZ Food Safety Compliance and CAMS-PM Maintenance Management solutions have electronic repository capabilities and specialize in data aggregation over time. Information entered into the systems can be queried and compiled into informative dashboards.

"These dashboards provide an overall view of a facility’s efforts and show where improvements need to be made. The visual aggregation of data allows management to better allocate resources and determine how to best mitigate risks," explains Burgh.

Using software for these sorts of tasks help product manufacturers with compliance related to traceability and other food safety concerns.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

"Having all food safety or maintenance information in one, comprehensive system allows standardization across departments and from a corporate perspective, across all facilities. Through a standardized system complete audit trails are easily maintained," remarks Burgh.

Within KLEANZ Food Safety and CAMS-PM Maintenance Management all actions are documented and searchable for audit purposes. The systems can also escalate non-conformances by sending alerts to managers.

"Therefore, impediments are not buried in binders but automatically given to the necessary employees and action can be taken immediately. Being able to immediately know where and how a food safety risk impacts product is crucial to traceability and software systems can provide the necessary oversight," he explains.

Although there are benefits of using a dedicated sanitation/maintenance software solution vs. working to integrate these tasks into a standard ERP platform, there are also downfalls.

"Not all electronic solutions are built equally. Certain solutions produce forms and can be retrofitted in attempts to accommodate sanitation and maintenance documentation within food manufacturing," says Burgh. "This method is almost always lacking in traceability and preventative solutions. Just because a system can produce an electronic schedule doesn’t mean it has the appropriate tools to optimize resource allocation or mitigate risks."

Simply put, general systems are not kept up to current standards, cannot track and trend based on regulatory requirements, and are not designed for critical Food Safety execution, he notes.

A company's approach toward sanitation and maintenance can factor into strategies for continuous improvement, too.

"For sanitation and maintenance, continuous improvement relies on adhering to corporate initiatives and the key performance indicators that go along with them," comments Burgh.

"We encourage our clients to imagine: 'What would your ideal Food Safety or Maintenance program look like in a year’s time?' Asking questions like these provides the groundwork to determine your organization’s definition of success."