Safe Quality Food Edition 9.0: Ambient Air Quality

The adoption of Global Food Safety Initiative-benchmarked food safety programs has significantly helped mitigate some of the dynamic complexities and uncertainties that most of us in the food industry face by providing a unified perspective in the definition, characterization, evaluation, and subsequential mitigation of foodborne hazards that may present public health concerns.

In this regard, one would gather that the task of drafting and codifying of a food certification scheme’s food safety code is one of the most challenging nodes within the contextual global ecosystems of the realm of food safety. We should all celebrate those professionals involved in these mentally draining challenges who bear this burden on our behalf to help provide certainty and sanity in an otherwise infinitely complex and uncertain universe.

Current food supply market conditions are in a state of perpetual flux as reflected in highly fluid trends, presenting a need for the constant revision of many certification schemes’ food safety program codes to not only reflect but actually augment the respective entity’s response to these changes.

As such, it takes a lot of time and effort to undertake and ratify a food safety code revision, given the importance of these codes as foundational frameworks of the food safety programs for many food production facilities.

As a production plant food safety professional in a Safe Quality Food (SQF)-certified food production facility, I am tasked with translating and implementing any requisite code requirement into the facility’s food safety management system.

As I was reviewing module 11 elements, I came across element 11.5.5.3: Ambient air shall be tested at least annually to confirm that it does not pose a risk to food safety. Immediately, a red flag appeared. In the realm of food safety, a risk assessment assumes a more probabilistic (global) than deterministic risk evaluation approach, which, as a food safety professional, I’ll admit is more often heavily weighted by a representative heuristic assessment than the adoption of a statistical assessment when evaluating the potential hazards that may present public health concerns pertinent to a facility’s food production operations. However, I must note that both are often considered jointly .

My alarmist (for the lack of a better word) question is: Why was this element mandated without a qualifying statement? Was it the result of the exclusive application of a representative heuristic assessment without the inclusion of a statistical approach?

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Having worked in a high hygienic zone-controlled environment of a high-risk product aseptic filling processing facility, I would 100 percent concur on the inclusion of this element as a requisite requirement without a qualifier.

However, working in a medium/ basic hygienic zone such as a bakery, I find it difficult to justify the conduction of an ambient air quality testing protocol, in terms of its validity.

What are the characteristics to be evaluated (particulate contaminants, biological, or chemical?)?

What are the test metrics? (These are quite complex tests that would require standardized test protocols such as the ones developed by the Institute of Environmental Sciences and Technology on contamination control standards and recommended practices.)

Could this be an example of a conjunction fallacy in the characterization of biological and chemical hazards in a production facility? If a facility’s environmental control program calls for the swabbing of food contact surfaces, aren’t these surfaces as susceptible to potential airborne contamination as the food articles being processing on the facility if we are to logically assess the airborne risk potential?

If we were to extend this logical argument from a statistical perspective [i.e., if we apply a statistical approach to this argument, going by the computed statistics from U.S. public health-related government agencies, such as the five year reportable Food Registry Report (RFR), the U.S. Centers for Disease Control and Prevention’s National Outbreak Reporting Systems (NORS), and the U.S. Department of Agriculture’s recalls and alerts], then there would be no need for risk-based food categorization into such groups as high-risk foods (e.g., such as raw meats, ready-to-eat pasteurized dairy and egg products), medium-risk foods such as canned foods, and low-risk food products, such as bread.

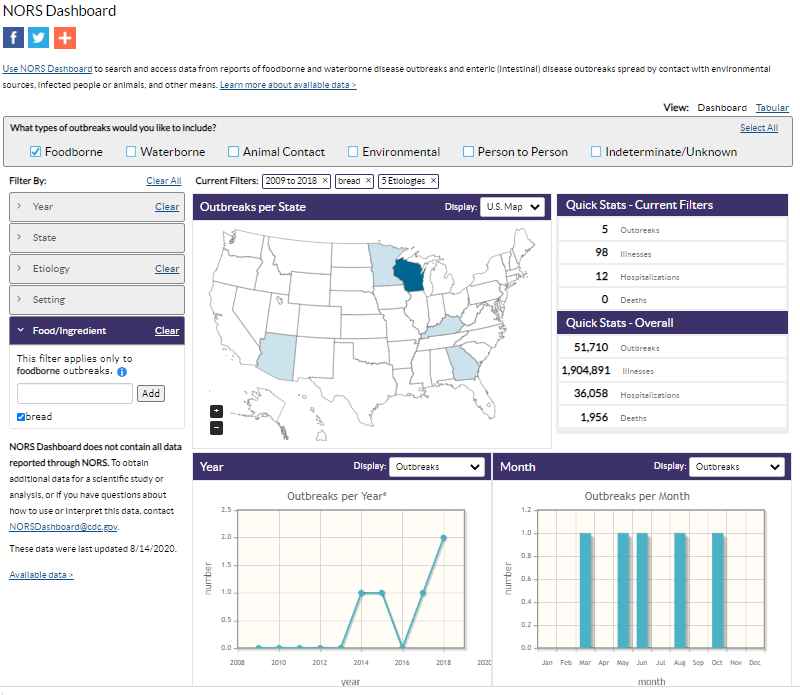

For example, if one were to run a query on the NORS database on foodborne outbreaks associated with normal bread products between 2009 and 2018, the search would return a very low incidence rate on a broad-based etiological agent filter (Figure 1).

Figure 1. NORS Dashboard (2009–2018)

Likewise, if one were to take a quick look at an RFR report, bakery, breakfast cereal, and snack food commodities registered zero entries for biological contaminants.

Of course, these are lagging indicators and one can never rule out the occurrence of a black swan event, like the emergence of an Escherichia coli threat in raw flour.

I think it would be prudent to add a qualifier to this requirement by rewriting this section in a manner that would provide a probabilistic (global view) rather than deterministic risk assessment of a plant’s production environment conditions. In my opinion, I would rewrite the section in this manner:

“The plant facility shall provide verification on the suitability of its of production environment ambient air towards the safe processing and handling of food products.” In my view, this approach would provide a wide latitude to many food safety programs to confirm the suitability of their facility’s ambient environmental conditions for the production of safe foods, either through published literature and data as espoused above for those facilities with basic or medium hygienic zones in their production layouts or through experimental analytical testing for those facilities with high hygienic zones within their facility layouts.

As the requirements stand, I can foresee facilities that rely on the SQF code to meet the compliance requirements for the Food Safety Modernization Act (FSMA), scrambling to create a binary food safety system (which actually is currently practiced by some): one that caters to SQF and one that caters to FSMA’s Preventive Controls rule requirements, since this requirement essentially compels all food safety establishments under SQF certification to designate their environmental monitoring programs to be requisite food safety controls regardless of their risk assessment (which amounts to a very slippery road when looking at it from a regulatory compliance perspective).

As noted above, a number of food safety professionals have burned the proverbial midnight oil to draft, review, and ratify the code requirements, and as such, these concerns about the requirements of this element may already be in the process of being addressed.

Patrick Embwaga is the quality manager at Franklin Street Bakery.

.webp?t=1721343192)