Traceability Progress in the Leafy Greens Sector

From July through the end of October, 2020, GS1 US worked with five other industry organizations and key industry stakeholders to simulate multiple recalls involving three different types of romaine lettuce products.

In response to the U.S. Food and Drug Administrations (FDA’s) initiatives for improved traceability in the produce supply chain, the Food Marketing Institute, GS1 US, the International Foodservice Distributors Association, the Institute of Food Technologists, Produce Marketing Association, and United Fresh focused these pilots on tracing leafy green products through actual consumer purchases made with loyalty cards or credit cards. Pilot results demonstrated an investigation can be conducted more effectively when supply chain partners gather pertinent information from each other that may not always be asked by investigators during tracebacks. The pilots also revealed that an enhanced standard template could improve the speed of tracing procedures.

These pilots just scratch the surface of what can be done to enhance food traceability processes in the leafy greens sector. A category that has too often been the subject of widespread foodborne illness outbreaks over the past several years, it represents an opportunity for the industry to collaborate and more fully leverage the digital tools available to them to pinpoint the source of harmful pathogens or other recall triggers.

Let’s examine more of the key findings of the 2020 Leafy Greens Traceability Pilots, which are sure to be key indicators of how traceability will evolve to meet consumer expectations for transparency, sustainability, and safety.

Existing Product Movement Information Led to Lot Identification

One of the most important findings placed great emphasis on existing product movement information. Extended data, gathered from a supplier (grower or processor) to a distribution center (retailer distribution center or third-party), into the store, and out through point-of-sale, was key to helping the industry experts successfully identify the lots from where the romaine originated.

Take a look at each pilot scenario below to see how each pilot varied in its structure but similarly leveraged the power of extended product data to enhance the traceability of the romaine:

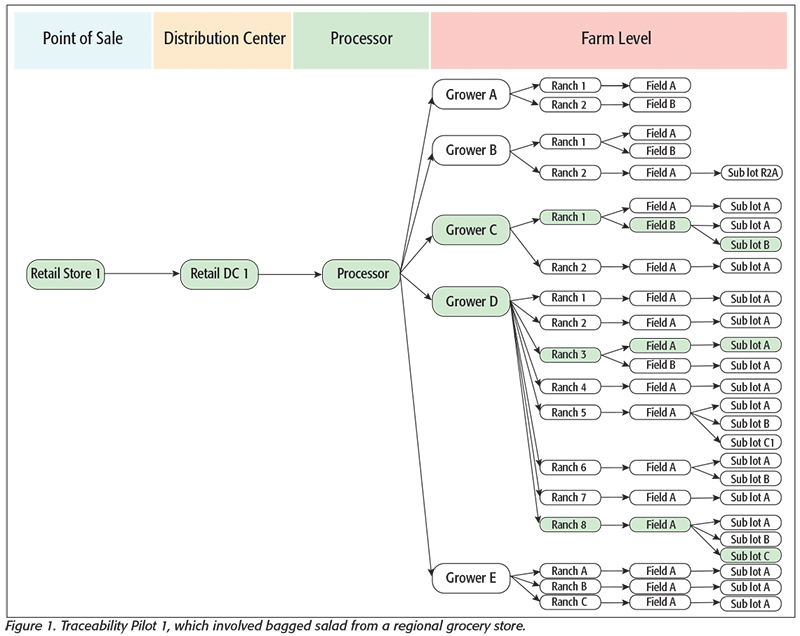

• Pilot 1: This pilot involved branded bagged salad from a regional chain grocery store. By understanding product movement in this supply chain, and by requesting additional information from the retailer and processor, the pilot team identified the single product lot, which traced back to two growers and a total of three ranch-field-sublot combinations (Figure 1).

• Pilot 1: This pilot involved branded bagged salad from a regional chain grocery store. By understanding product movement in this supply chain, and by requesting additional information from the retailer and processor, the pilot team identified the single product lot, which traced back to two growers and a total of three ranch-field-sublot combinations (Figure 1).

• Pilot 2: This pilot involved romaine hearts sold at an independent retailer that used a third-party distributor. By understanding product movement in this supply chain, pilot team 2 was successful in identifying the two lot numbers of the finished product that could have been purchased by the consumer.

• Pilot 3: This pilot involved private label salad (under U.S. Department of Agriculture jurisdiction) from a national chain store. Due to the fact the product had been out of stock prior to the consumer purchase, this “clean break” allowed pilot team 3 to identify two possible finished product lot numbers on the purchase date.

Raising Awareness of Information Available at Each Step

Each of the three expert teams that conducted the tracebacks reported a better understanding of the traceback process and were occasionally surprised by which points in the supply chain retained different pieces of information. In all pilots, the teams augmented their requests for industry information and data beyond the scope of the key data elements identified in the traceback template. It was these other data requests that proved critical in identifying the finished product lot number associated with the purchase of interest. Here are some examples of the types of information and the value they provided:

Shopper and credit card data: These data were valuable because they included purchase dates, which created “hard stops.” In other words, product that was not yet available for purchase was easily determined to be outside the scope of the data request. There is an opportunity to standardize the way purchase information is requested by regulators so that sufficient context is provided.

Inventory, sales and other business intelligence: Based on the purchase date, each team then determined the date range for which to request records. Although two teams started with broad requests (based on assumed or reported product shelf life) and one team began more narrowly, ultimately each team based their final identification of the purchased lot code based on their understanding of product flow through the supply chain. While the industry participants captured slightly different information, each retailer still had a detailed accounting of product sales at the store level. This paired with information on replenishment (based on shipments from a distribution center, receipts at a store, and/or restocking procedures) enabled each team to accurately determine the finished product lot codes available for purchase. Buyer requirements such as the number of days of shelf life that must remain also helped narrow the scope of the request and were used in the interpretation of product movement.

Traceback Template Improvements

The main benefit of using the standard template was that it was a helpful tool in summarizing data that each supply chain participant may have had in disparate places (e.g., different software systems, different pieces of paperwork, etc.). However, the detailed information (including both master data as well as transactional data) overwhelmed many of the industry participants, and the expert teams reported that only narrow subsets of the data were used to link product as it moved through the supply chain.

Regardless of the edits and adjustments to the template, it became clear that education and training will be needed to encourage adoption and consistency in use. In some cases, participants suggested more automation of the template to provide this consistency and aid in establishing linkages to each data set. This includes drop-down menus and rules to standardize the way information is conveyed (e.g., standardizing state abbreviations, limiting the number of digits in product identification fields).

Ultimately, these pilots are by no means representative of the multitude of supply chains configurations and nuances associated with traceability. However, this exercise was important to show that, despite criticisms of the ability to trace leafy greens through the supply chain, each pilot team was able to narrow down the lot code of the hypothetical “contaminated product” purchased by the consumer, which allowed for the identification of inputs into the finished product. In this regard, the association partners view the pilot as a call to collaborate and encourage interested stakeholders to collaborate on similar tests or mock recalls to gain additional learnings.

Angela Fernandez is Vice President of Community Engagement at GS1 US.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →