AllergenControl™ Detection Kits Have Features Found Nowhere Else

For the majority of the general public, the consumption of food is beneficial and harmless. Nonetheless, food allergies are highly dangerous for consumers, because they are caused by errant immune reactions, which are usually triggered by proteins. Indeed, they may cause life-threatening reactions in food-allergic subjects and dramatically restrict the quality of life. Scientists estimate that approximately 2–3% of adults and 6–8% of children suffer from food allergies.

Allergens in Food Must Be Labeled

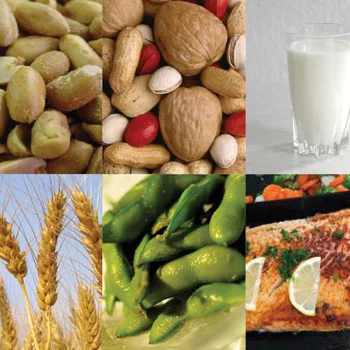

The U.S. Food and Drug Administration says undeclared allergens cause the majority of recalls. The “Big 8” foods account for 90% of allergic reactions: milk, eggs, fish, crustacean shellfish, tree nuts, peanuts, wheat and soybeans.

Food labels must identify whether a product contains any of these major food allergens. Since products not specifically formulated with these allergenic ingredients may still contain traces of them as a result of cross-contamination during processing—for example, as a result of inadequate cleaning during changeover of equipment—food and beverage manufacturers and ingredient suppliers must therefore test for the presence of these allergens in their products.

Why a Food Business Needs a Food Allergen Management Plan

Most production lines process more than one item. This may result in unintended contamination with allergens. The only certain way to avoid a recall for mislabeling is testing as low as possible for any indication of allergen residue. Current regulations have not established a threshold for defining allergen residue levels. Under these circumstances, processors are advised to use test methods that are highly sensitive as a best practice to avoid a recall for mislabeling.

ELISA Systems® kits have a limit of detection (LOD) that ranges from 0.1 to 1.0 ppm targeted protein. According to Fred Weber, president of Weber Scientific, “The ELISA Systems’ Lateral Flow Device [LFD] has been thoroughly validated. Additionally, they offer superior benefits over other kits. They are available for either environmental or food residue in a single kit configuration, and with our competitive custom pricing, they are also the most affordable test available.”

Assay Principles

The AllergenControl™ residue LFD features polyclonal antibodies directed against targeted proteins configured in both sandwich and competitive formats. To operate the kit, the sample is first subjected to a short extraction step. The sample extract is then directly applied to the LFD sample port, where it is allowed to migrate across the reagent zone, thus enabling visualization of the sandwich test line (T) and competitive test line (0) results. In addition, the reagent zone includes a procedural control line (C) to minimize the potential for false-negative outcomes.

The reagent zone contains three distinct print lines that must be considered together when interpreting the test lines. The T will become clearly visible at the LOD value defined for the kit and continue to strengthen in intensity with increasing target analyte concentration up to the point where it will then start to fade and eventually disappear at high analyte levels. The 0 will be intense if the sample is negative for the target analyte and fade with increasing amounts of analyte, disappearing completely at high analyte levels before the T does. This feature allows the operator to distinguish samples with no or low levels of target analyte from those with high levels. The C also enables detection of target analyte that is highly hydrolyzed and poorly detected by the T. Failure of the C to appear denotes an invalid test, requiring repeat testing. Performance characteristics:

• Verified to avoid cross-reactivity

• LOD of 1.0 µg protein/g

• Sample extraction time: 1–15 minutes

• Test operation time: 15 minutes

Why ELISA Systems Kits Are Special

Avoid waste: Kits are available for either environmental surface tests or food product tests. Plus, kits are available individually. Buy only what you need.

Doesn’t need refrigeration: Store at 36 °F–77 °F (2 °C–25 °C).

Simple to use: No reconstitution of reagents; simply extract and run.

Added security of the C to prevent false negatives: Some LFDs can give false negatives when high levels of food allergen are present in the sample.

Wide range of kits available for specificity: For example, you can choose from total milk, casein or beta-lactoglobulin residue. Overall, 22 kits are available.

Samples are tested against supplied known controls.

Heat-stable protein allergens are detected.

ELISA Systems products are distributed by Weber Scientific with free samples available.

www.weberscientific.com

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →