Atmospheric Plasma Technology in the Meat Industry

Food technology has reached new levels of innovation in the effort to ensure product safety, driven by consumer demands and government regulations to produce “bacteria-free” foods. Consumers are seeking more nutritious, less processed foods, while simultaneously expecting “bacteria-free” products of high quality and long shelf life.

According to Centers for Disease Control and Prevention (CDC) findings as of 2011, foodborne illnesses have been estimated at 48 million, with 128,000 hospitalizations and 3,000 deaths in the United States each year alone.[1] Of these, an estimated annual 9.6 million illnesses (20%), 56,320 hospitalizations (44%) and 1,320 deaths (44%) have been caused by known foodborne pathogens.[1] The meat and poultry industry has been a leader in the development and implementation of new processing technologies. Some of the novel food processing technologies growing in use include high-pressure processing (HPP), pulsed light, ultraviolet (UV) light, e-beam and X-ray. Another recently developed technology that shows significant potential to meat and poultry processing is atmospheric plasma.

The Promises of Plasma

Atmospheric plasmas containing high levels of bactericidal molecules (> 100 ppm ozone, nitric oxides, peroxides, etc.) are generated with minimal power under room-temperature conditions in seconds to minutes, with little or no product heating. Atmospheric plasma technology (APT) requires a few hundred watts of power and a supply of compressed air or other gas; sometimes, a gas blend is used depending on the reactive gas species being generated. APT can generate bactericidal molecules in situ very efficiently solely from air with product temperature increases less than 5 °C.[2] This flexibility and unique processing capabilities are driving the technology into new markets and applications. Atmospheric plasma offers a number of advantages over existing food safety technologies, including the following: 1) it is a dry process; 2) it is readily adaptable to a food manufacturing environment; 3) it requires very little energy; 4) reactive gas species revert back to original gas within minutes to hours after treatment and 5) it requires short treatment times. This article will highlight atmospheric plasma systems, the current state of the technology, its regulatory status and future opportunities in the meat industry.

Just What Is Atmospheric Plasma?

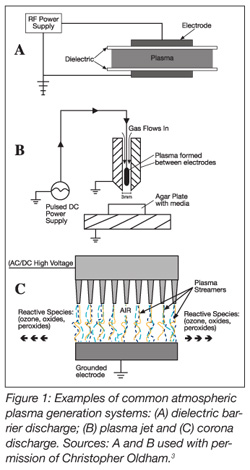

Plasmas are recognized as the fourth state of matter and result from applying energy (heat, voltage or light) to a gas, initiating a breakdown of individual gas molecules into free electrons, ions and metastable species.[3] Industrial plasma systems have been in use for more than 150 years. The first atmospheric pressure plasma was invented by Werner von Siemens in 1857.[3] This system was a dielectric barrier discharge (DBD) system that passed air between two parallel plates with a voltage differential to generate ozone. This method is still in use today in ozone generation systems. Over the years, many adaptations have been developed, including corona discharge, atmospheric plasma jet, pulsed plasma, microplasma, nanopulse plasma and many more.[4]

A major driving force in the development of industrial plasma systems has been the semiconductor industry. Initially, silicon wafers used in the computer industry were cleaned in chemical baths until recognition that low-pressure (i.e., vacuum) plasmas could meet this need in a completely dry—that is, less polluting—process. Further development generated atmospheric pressure, low-temperature air plasmas with unique capabilities to clean surfaces and alter surface properties (e.g., change a hydrophobic surface to a hydrophilic surface). This process is currently being used on the surface of packaging materials to improve adhesion of printing inks.[4] Atmospheric low-temperature plasma has attracted significant interest in the last 10 years because of its ability to inactivate biological agents, reduce foodborne microorganisms and aid in medical treatments.[5]

Food safety intervention technologies used in the meat industry encompass many areas of manufacturing. These include slaughter, meat product fabrication (e.g., cutting, blending and extruding), further processing (e.g., cooking, curing, drying and freezing) and packaging. In addition, numerous prerequisite programs also utilize intervention technologies to ensure a sanitary manufacturing environment, such as operational sanitation, preoperational sanitation, air handling and preventive maintenance. Decontamination of food and food contact surfaces is necessary to meet food safety regulations and industry standards. Ease of implementation into existing processing lines, compatibility with existing sanitation practices and rapid decontamination make APT a cost-effective measure for meeting consumer demands as well as mounting government food safety requirements.

APT offers a wide selection of gas compositions, generation methods and methods of product exposure, which all influence the concentration of the generated reactant products (e.g., ozone, peroxides and monoxides) and their resultant impact on the meat or poultry product. Nonthermal plasmas are produced under conditions in which the bulk gas temperature is much lower than the free-electron temperature (~ 5,000 K). For food exposure, plasma bulk gas temperature should be around room temperature (25 °C–50 °C). Ionized gases generated from APT can create unique conditions that have no thermal equivalent. For example, using air, one can generate high levels (> 1,000 ppm) of reactive oxygen and nitrogen species (e.g., ozone, oxides, peroxides and monoxides) in seconds with minimal power, heating and time.[6] Plasmas can be generated in any gas composition (e.g., air, He, N{2}, Ar, Ne, CO{2}) with either direct or alternating current voltages. APT lifetimes for reactive species of oxygen, N{2}, H{2}O and CO{2} range from a few seconds to hundreds of minutes. Many of these species have significant bactericidal properties. Because of its low power requirement, low temperature and short treatment times, APT shows promise for bactericidal treatment without harming food quality.

APT systems come in three general categories: DBD, plasma jet and corona discharge. DBD utilizes a high-voltage field applied between two electrodes, ionizing the gas passing between them. A schematic of a DBD is shown in Figure 1A. Like the DBD, a plasma jet generates plasma between two plates; however, this plate gap is very narrow and pressurized gas is passed through the ionization field, creating plasma that is exhausted out a nozzle onto the surface to be treated. A schematic of a plasma jet is shown in Figure 1B. A microscale version of a plasma jet is referred to as a microplasma jet. Large numbers of plasma jets (or microplasma jets) can be assembled to create systems capable of uniformly treating very large areas, such as conveyors. Another common system of plasma generation is a corona discharge. A corona discharge results when a minimal electrical resistance is present; a high voltage is applied that generates streamers (i.e., miniature lightning bolts). These streamers are high-temperature plasma “bursts” that are used primarily to clean surfaces or alter surface properties. The corona discharge is less likely to be used in direct processing of food because the streamers probably would produce localized product defects (e.g., burn spots, discoloration, oxidation, etc.). A schematic of a corona discharge is shown in Figure 1C.

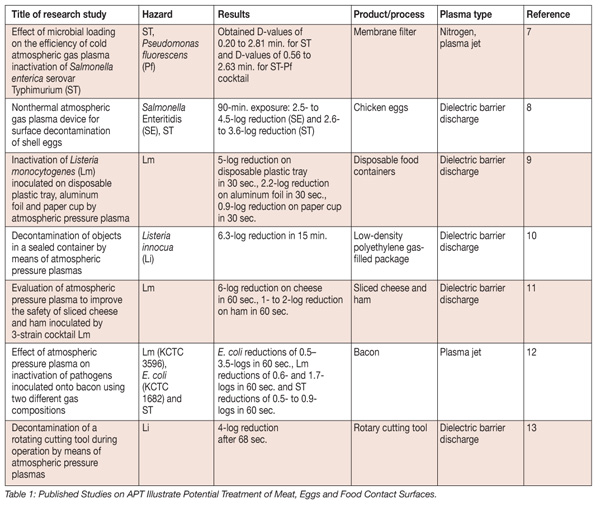

Table 1[7–13] highlights some recently published studies on APT treatment of meat and meat-related bacteria. These studies are a snapshot of ongoing food safety research on APT. These studies demonstrate the use of APT in meat and poultry processing, including in-line disinfection for food contact surfaces (e.g., feeder lines, cutting blades, conveyor belts), pathogen and/or biofilm reduction control of ready-to-eat meat and poultry products and effective treatment/disinfection of package materials and in-package products. While the studies are limited, results have shown bacterial reductions from APT range between 0.5 logs to greater than 6 logs (reduction of 1,000,000). Further research is still needed to determine APT’s effects on food quality. In addition, further reduction in treatment times and optimization of APT processes are needed before it can be used in meat and poultry processing plants. Because food safety is the primary driver of regulatory policy, increased studies on APT are expected with more exciting results yet to be discovered.

APT Consensus

As with any new technology, regulatory review and a letter of nonrejection are necessary to begin commercial trials. One of the primary reactive oxygen species generated with APT is ozone (considered GRAS: generally recognized as safe) along with many other reactive gas species (e.g., oxides, monoxides and peroxides) that require characterization. If the plasma generated directly contacts the food, then characterization of the food-plasma chemistry is required. This regulatory review process may take considerable time and effort.

To further develop and evaluate this technology for the U.S. meat and poultry industry, an association or organization needs to take the lead and develop a consortium of interested parties, including participation of the U.S. Food and Drug Administration (FDA) and/or U.S. Department of Agriculture (USDA). This consortium can then coordinate the design of research studies to satisfactorily address questions posed by FDA and USDA to clearly demonstrate adequate safety and effectiveness of APT for meat and poultry products, food contact surfaces and the packaging materials. The extensive list of potential applications for this technology outweigh the regulatory hurdle that lay ahead.

APT’s benefits for the meat and poultry industry are numerous. APT allows for product customization from container capacity, ionization levels and package types to the combination of APT treatment in tandem, or in combination, with current traditional processing methods. This adaptability of product customization will allow APT to further enhance meat processing by increasing safety, maintaining quality and extending product shelf life. The current advantages that atmospheric plasma offers include increased product safety by reducing or eliminating foodborne pathogens such as Listeria spp., E. coli strains and Salmonella spp. (protecting a company’s bottom line and reputation); increased product quality and freshness by the destruction of spoilage organisms and increasing product shelf life; increased preservation of organoleptic properties of meat product due to nonthermal treatment processes and reduction or elimination of chemical preservatives (resulting in cost savings to companies), yielding a “clean” labeled product (all natural, organic, etc.), which is a favorable outcome to many consumers.

While a “bacteria-free” food acceptable to consumers is not practical at present, consumer and government expectations will continue to demand enhancements in our existing food safety strategies. Furthermore, the battle between man and microorganisms is ongoing, with an ever-changing landscape. For the prudent processor, APT may be another weapon against food bacteria.

Kevin Keener, Ph.D., P.E., is the director of the Food Processing Environmental Assistance Center at Purdue University and an associate professor in the department of food science at Purdue University with an associate faculty appointment in agriculture and biological engineering. He provides educational training and technical assistance to government agencies, food companies, equipment manufacturers and food entrepreneurs in food safety, food technology, food regulations, food sanitation and energy conservation. His research interests include development and commercialization of food processing technologies.

Jean Jensen is a research scientist in the department of food science at Purdue University and holds a B.Sc. in biochemistry. Her expertise lies in research and development, analytical chemistry, and quality control and assurance evaluation. She is the lab manager of the Food Technology Development Laboratory at Purdue and the coordinator of the Food Processing and Environmental Assistance Center.

References

1. www.cdc.gov/foodborneburden/2011-foodborne-estimates.html.

2. Klockow, P. and K.M. Keener. 2009. Safety and quality assessment of packaged spinach treated with a novel ozone generation system. Lebensmittel-Wissenschaft und Technologie 42(6):1047–1053.

3. Keener, K.M. 2010. Atmospheric, nonequilibrium plasma, in Encyclopedia of Agricultural, Food and Biological Engineering, 2nd ed., eds. Heldman and Morarau. 1:1–5.

4. enviro.fmph.uniba.sk/nato/html/ documents.html.

5. plasticsnetwork.files.wordpress.com/2007/ 12/corona-treatment.pdf.

6. Keener, K.M., J.L. Jensen, V.P. Valdramidis, E. Byrne, J. Connolly, J.P. Mosnier and P.J. Cullen. 2011. Decontamination of Bacillus subtilis spores in a sealed package using a non-thermal plasma system. Presentation # O5. NATO Advanced Research Workshop: Plasma for Bio-Decontamination, Medicine and Food Security. Jasna, Slovakia.

7. Fernandez, A., N. Shearer, D.R. Wilson and A. Thompson. 2011. Effect of microbial loading on the efficiency of cold atmospheric gas plasma inactivation of Salmonella enterica serovar Typhimurium. Int J Food Microbiol [Epub ahead of print].

8. Ragni, L., A. Berardinelli, L. Vannini, C. Montanari, F. Sirri, M.E. Guerzoni, A. Guarnieri. 2010. Nonthermal atmospheric gas plasma device for surface decontamination of shell eggs. J Food Eng 100:125–132.

9. Yun, H., B. Kim, S. Jung, Z.A. Kruk, D.B. Kim, W. Choe and C. Jo. 2010. Inactivation of Listeria monocytogenes inoculated on disposable plastic tray, aluminum foil, and paper cup by atmospheric pressure plasma. Food Control 21:1182–1186.

10. Leipold, F., N. Schultz-Jensen, Y. Kusano, H. Bindslev and T. Jacobsen. 2011. Decontamination of objects in a sealed container by means of atmospheric pressure plasmas. Food Control 12(8):1296–1301.

11. Song, H.P., B. Kim, J.H. Choe, S. Jung, S.Y. Moon, W. Choe, C. Jo. 2009. Evaluation of atmospheric pressure plasma to improve the safety of sliced cheese and ham inoculated by 3-strain cocktail Listeria monocytogenes. Food Microbiol 26:432–436.

12. Kim, B., H. Yun, S. Jung, Y. Jung, H. Jung, W. Choe and C. Jo. 2011. Effect of atmospheric pressure plasma on inactivation of pathogens inoculated onto bacon using two different gas compositions. Food Microbiol 28:9-13.

13. Leipold, F., Y. Kusano, F. Hansen and T. Jacobsen. 2010. Decontamination of a rotating cutting tool during operation by means of atmospheric pressure plasmas. Food Control 21:1194–1198. >

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →