Fine-tuning industry-specific inspection/detection lines

Inspection and detection lines are extremely important in the food safety industry, for obvious reasons—there already are enough recalls that occur, so if a machine can help prevent those, it can be highly useful.

Unique features for specific industries

“Equipment that processes dairy, meat, and/or poultry will often require special USDA certification,” says Todd Grube, product manager, inspection systems, Heat and Control, Hayward, CA.

CEIA now offers their THS/MS21 metal detector with optional USDA construction compliance certification for installations that must meet the USDA’s stringent hygiene and sanitation guidelines, he says.

“This USDA Dairy and Meat & Poultry-approved design eliminates any difficult to clean areas, which could harbor bacteria,” he explains.

Mettler Toledo’s Profile Advantage metal detector has features that make it capable of inspecting baked products that are changing in their conductive characteristics as they change temperature after being baked, or meats that are moisture-laden as they thaw after being frozen. These are challenges that can defeat traditional metal detectors, which work best when the products being inspected are stable.

By suppressing those false signals, the Profile Advantage inspects products at full sensitivity, ensuring more effective inspection, maximizing product safety and protecting a company’s brand image.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Profile Advantage metal detectors also incorporate advanced Condition Monitoring technology that assesses the performance and operation of key detector components and circuitry. Operators are alerted of adverse trends or changes in performance that can potentially cause system downtime, giving them advanced warning before a problem occurs. When fitted with METTLER TOLEDO’s optional Due Diligence Enhancement Software Package, Profile Advantage can provide an even higher level of system integrity that delivers total system performance and ensures the highest level of metal detection.

The nature of meat and poultry products and processing environments calls for certain considerations in inline x-ray inspection and fat analysis, says Christy Draus, marketing manager, Eagle Product Inspection, Lutz, FL.

“For example, it can be hard to find bone fragments as well as metal and other contaminants in meat products, a challenge that is overcome with technologies like Eagle’s Material Discrimination X-Ray (MDX) technology,” she explains.

MDX uses differential x-ray energy absorbance to discriminate between organic and inorganic materials, a capability that is crucial in “busy” images of meat, Draus says.

“The latest generation of MDX technology features new detector configurations and advanced algorithms. The technology was recently incorporated into the Eagle RMI 400 system. This versatile system can inspect raw and unpackaged products and enables reliable bone and contaminant detection, including the detection of non-bone materials like tendon and quall,” she adds.

The new technology improves the level of bone and contaminant detection with a 3-4 times resolution improvement and reduced false rejects, Draus notes.

“For enhanced safety and sanitation, the machine includes an innovative incline design with no curtains, which limits the number of surfaces with which the product comes into contact,” she explains.

In the dairy sector, environments pose unique challenges, particularly for sanitation, Draus says.

“To help dairy manufacturers comply with regulations and meet their own continuous improvement goals, Eagle recently updated its Pack 400 HC, a hygienic machine that has passed third-party verification for 3-A symbol authorization,” she remarks.

The 400 HC is designed for harsh washdown environments like dairy processing plants, with features like welded stainless steel plates, tool-less belt removal, interlocked hinged louvers, and a specially designed cabinet that deflects water away from the machine. The hygienic machine conforms to 3A sanitary design standards and is ideal for inspecting items like raw unpackaged blocks of cheese. It allows for easy and efficient cleaning in harsh wash-down environments, says Draus.

“The multifunctional 400 HC also helps dairy manufacturers improve productivity by conducting important quality checks like fill level, mass measurement and seal inspection, including cap or closure placement. Manufacturers can utilize the system to determine if there are any voids within products like blocks of cheese and to prevent costly giveaway.”

In the beverage industry, those who produce beverages in cans and bottles can take advantage of application-specific inspection system, like the Eagle’s Tall PRO XS, she says.

“That machine provides 100 percent inspection for hard-to-find contaminants in tall, rigid containers including glass, metal and ceramic. The system can run at line rates in excess of 1000 PPM and is multi-functional in its ability to simultaneously scan for foreign bodies and perform inline product integrity checks such as fill level and cap or lid detection for bottles. By conducting fill level checks, with automated adjustment, a beverage maker can avoid under or overfilled containers and improve line efficiencies.”

In the snack industry, the increasing number of bakery products on the market, driven by consumers’ changing eating habits and preferences, includes a greater diversity of product and package types, comments Draus.

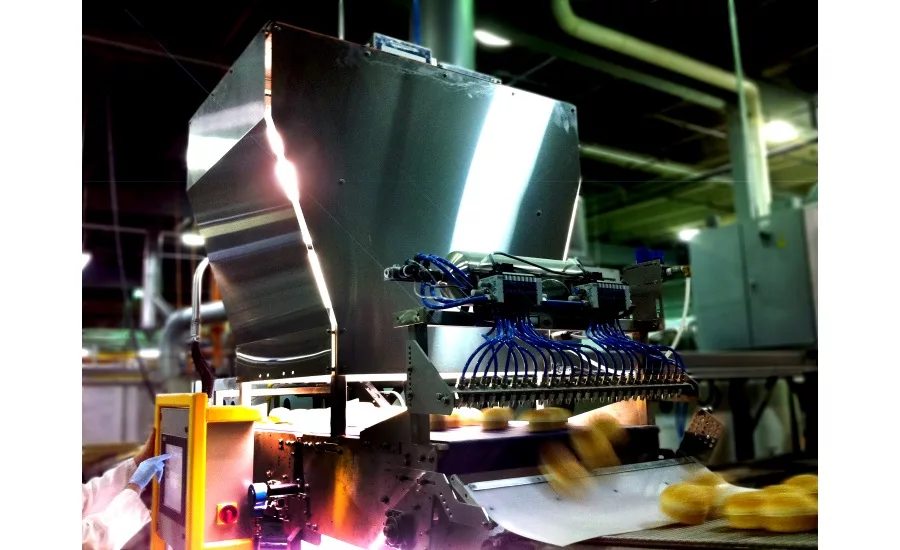

“Many manufacturers are running more products, often in shorter cycles, leading them to look for greater versatility from their inspection systems for safety and quality. Advanced inspection systems can be used to inspect bulk-flow (loose) products before they are packaged or added as an ingredient to a finished product as well as unpackaged foods like donuts, baguettes, buns, crackers and bread. For packaged products, x-ray systems ensure high levels of safety and integrity for a variety of items, spanning cartons/boxes, pouches, bags and trays, in addition to rigid containers in upright formats.”

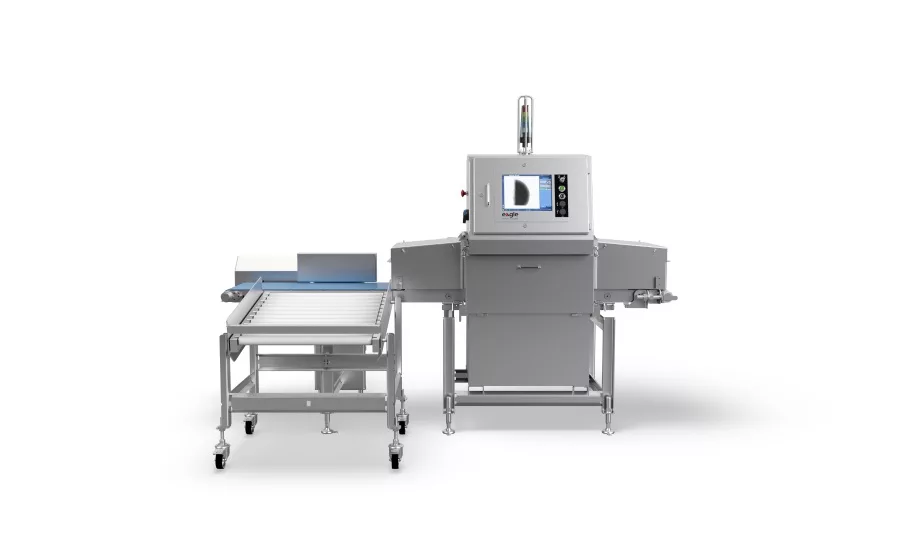

One example of a system that addresses the need for versatility in the bakery industry and other marketplace factors is the new EPX100 from Eagle, says Draus.

“Designed to inspect a broad range of packaged foods, the machine uses x-ray technology to detect and reject contaminants including glass shards, metal fragments, mineral stone, some plastic and rubber compounds and calcified bones, in packages including cartons, boxes, plastic containers and pouches. The smaller-footprint EPX100 has a lower-energy x-ray environment and doesn’t require extra or extensive radiation shielding. “

Many bakery and snack lines are multi-lane operations, which can be a challenge for inspection and rejections, she adds.

“The Eagle Pack 720 coupled with proprietary SimulTask PRO x-ray image analysis software allows manufacturers to inspect each lane independently and reject products for contaminant or quality issues resulting in improved production efficiencies and product quality.”

For ready-to-eat meals, because they meals usually contain multiple ingredients, including those sourced from different suppliers, and because they are often produced in different phases, these products are especially vulnerable to foreign contaminants, explains Draus.

“As demand for ready meals increases, x-ray systems can help find contaminants in packages with multiple ingredients and in multiple compartments, including glass shards, metal fragments (including metal within foil and metalized film packaging), mineral stone, calcified bone, and some rubber and plastic compounds. Eagle’s proprietary SimulTask software allows for more reliable detection in ready meals that inherently have more variation.”

Among other systems for ready meal applications, Eagle offers the Pack 320 PRO machine that enables enhanced contaminant detection and package inspection in high-speed flow-wrap lines and in small to mid-sized packaged products, she says.

“In addition, Eagle’s new EPX100 is used in ready meal inspection to enhance food safety and product quality in cartons, pouches, plastic containers and items wrapped in foil or metalized films.”

More reliable, faster, accurate

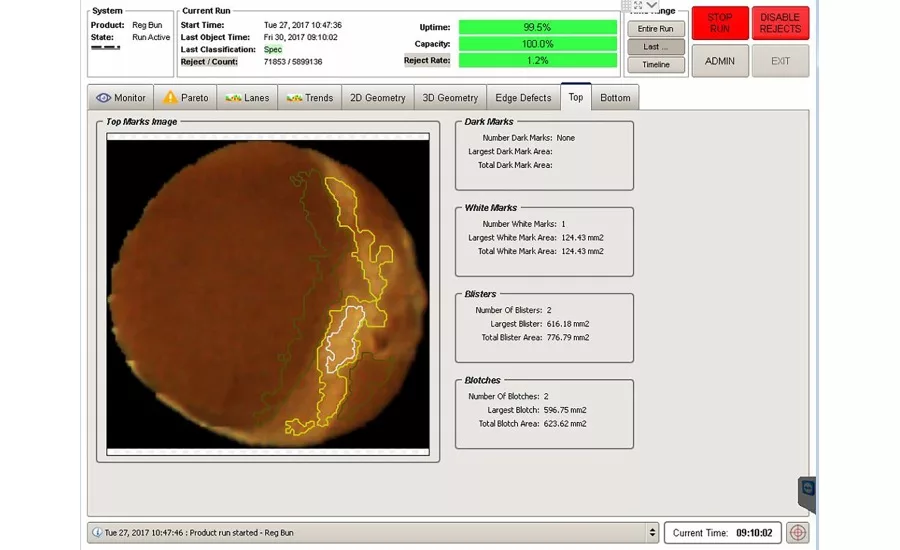

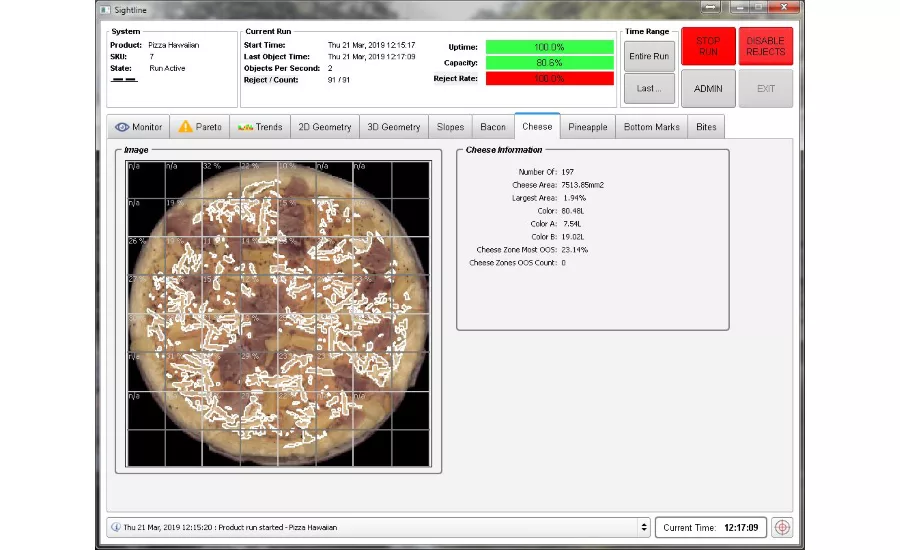

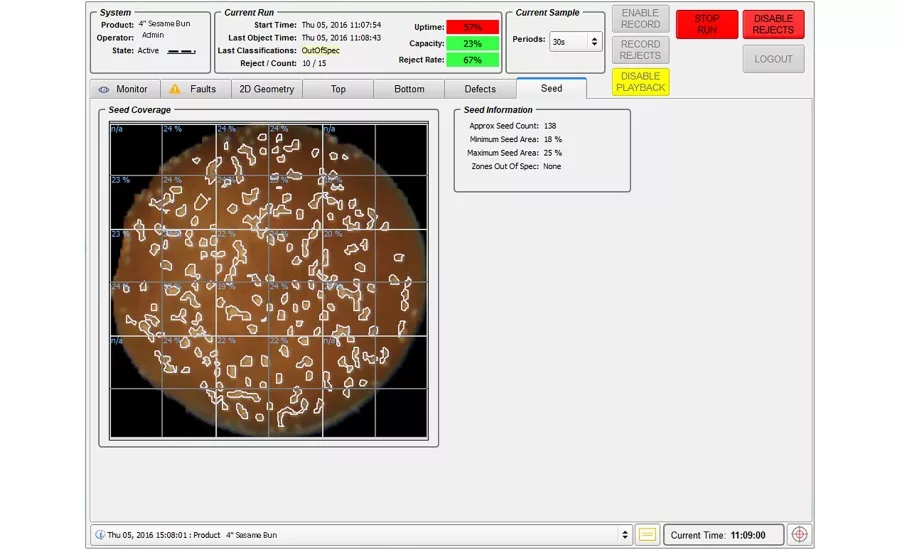

“Sightline systems are non-contact inspection systems that use a series of high-resolution/high-speed cameras, along with imaging software to detect and measure random objects as they move along a conveyor belt. Virtually any size, shape or color attribute can be extracted from the object images and converted into standard units, providing real-time 100 percent inspection of any production line,” says John Lawrence, CEO, Sightline Process Control, Inc., Ottawa, ON, Canada.

The manufacture of baked goods provides many challenges since there is a multitude of variables that can affect product quality, he says.

“The ability to continuously monitor key product attributes (e.g. bake color, peak height, slopes, blister area, etc.) in a quantifiable way, based on user-defined specification and rejection limits, provides the opportunity to respond to changes faster and more effectively. Sightline’s Measura real-time inspection software and can handle hundreds of unique products and each product can be “setup” to measure several attributes. Each active measurement can have its own specification limits (LSL/USL) and, if desired, separate rejection limits (LRL/URL) that will drive automatic rejection of objects that are outside these limits,” Lawrence notes.

The problem with manual measurements is that results are based on subjective analysis, he adds.

“Each person may measure an object differently based on opinion, physical ability, personal experiences, etc. Data collected manually takes more time and may not provide accurate representations of product quality and processes. Sightline inspection systems are designed to provide critical measurements faster and with better accuracy & repeatability than manual measurements, while providing the ability to measure and quantify product attributes that are difficult or impossible to calculate manually (e.g. surface area, color, volume, topping, etc).”

The highly optimized acquisition software allows objects to be captured at speeds of up to 100 per second, and 400 ft/min, so no matter what you make or how fast you make it, the software can keep up, he states.

“Deploying a Sightline system eliminates the need for data entry and manual charting, saving time and ensuring more reliable and repeatable QA results. All data is automatically recorded and saved to an SQL database on your network. Multiple report formats are available and can be served via automated emails as needed. More data for less effort.”

The Ishida checkweighers’ high output load cells along with precision guaranteed maximum price construction provide enhanced sensitivity over all other conventional strain-gauge technology, says Bill Nutting, product manager/sales-DACS, Heat and Control.

“Ishida load cells allow weight to stabilize quickly, providing best accuracy and faster weighing speeds. The Ishida human machine interface (HMI) is one of the most user-friendly HMIs on the market, reducing operator time and errors during operation. Also, it provides a full range to statistical information for data management,” he explains.

Heat and Control offers a complete line of checkweighing solutions manufactured by Ishida to cover small lightweight products as well as large cases in dry and washdown environments.

“These highly accurate systems provide unparalleled accuracies in any production environment, and their patented load cell technology insures the highest level of performance, while user-friendly interfaces provides customers with detailed performance data. A fail-safe function prevents defective items from being mixed in with products for shipment—even if there is a fault in the connected sorting device,” Brian Barr, sales manager, packaging systems division, Heat and Control, adds.

Ishida IX-GN and IX-EN X-ray detectors incorporate their patented Genetic Algorithm (GA) image processing which delivers superior accuracy, Grube says.

“In addition to the flexible customization options for GA setting creation, many typical GA settings are already stored on the machine, streamlining set-up. Also, up to four (4) different GA settings can exist at the same time on the IX-GN series units, and up to two (2) different GA on the economically priced IX-EN models.”

In addition to the industry's highest sensitivity to all magnetic and non-magnetic metals, including stainless steel, CEIA THS/MS21 metal detectors accurately differentiate between product effect and metal contaminants with no need to reduce sensitivity, Grube remarks.

“Designed for the most difficult products with strong product effect, only CEIA THS/MS21 multi-spectrum metal detectors use multiple detection frequencies simultaneously, along with advanced autolearn functions, to deliver the greatest sensitivity to all magnetic and non-magnetic metals and accurately compensate for product effect to reduce waste and false reject signals without reducing sensitivity.”

.webp?t=1721343192)