Equipment design and sanitary facilities

Equipment, technology and more featured in the "Sanitary facility and equipment design" article.

A process air handler, such as the one pictured here, can cool and dehumidify, provide outside air for room pressurization and filter the air to the level required by the process. Courtesy of: Hixson Architecture & Engineering.

Sanitary design was a key concern managed through design and engineering provided by Hixson Architecture & Engineering in this all-new $660 million poultry processing facility currently under construction for Maple Leaf Foods. Courtesy of: Hixson Architecture & Engineering.

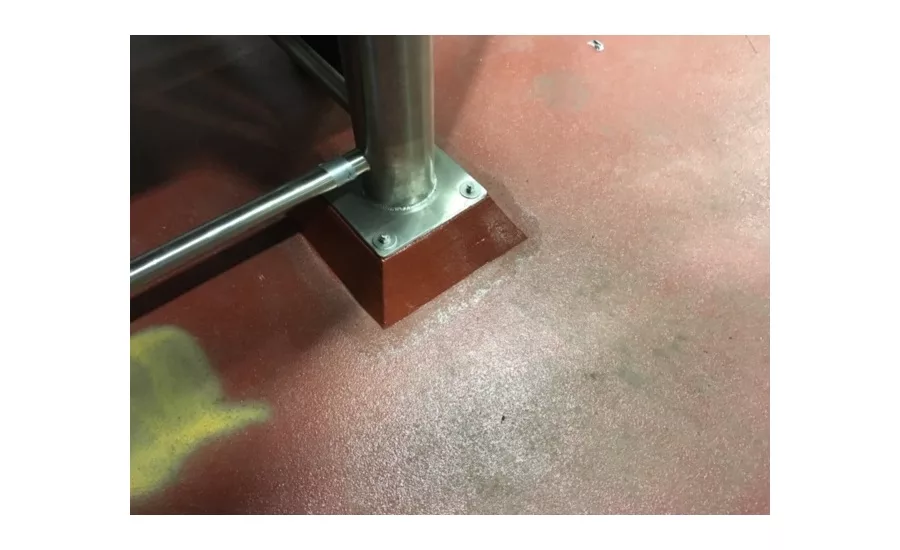

Hygienic equipment leg grouting. Courtesy of: Stonhard.

Condensation on the ceiling in a food processing area. Courtesy of: 3-A Sanitary Standards.

Another photo of ceiling condensation over open product. Courtesy of: 3-A Sanitary Standards.

Open plant. Courtesy of: Food Plant Engineering.

Never miss the latest news and trends driving the food safety industry

Newsletters | Website | eMagazine

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing