Food Manufacturer & Processor

Chobani Expands Idaho Innovation Center

New facility to deepen company's commitment to employees, local communities and the future of US manufacturing

November 13, 2017

Materials Technology: Shelf-life extending packaging

How spoilage-stopping solutions can combat a global crisis

Packaging technologies fight food waste

November 10, 2017

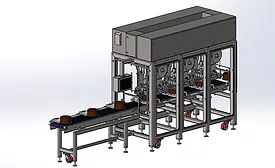

A step change in digital sorting

As technology evolves, there are times when changes are incremental and times when step changes occur in a way that massively disrupts the status quo. Digital sorting has recently experienced such a step change.

November 9, 2017

CoreFX Ingredients Opens Chicago Innovation Center

Company inaugurates 5,000-square-foot Innovation Center after just over a year in business

November 7, 2017

Good cleaning practices start before a plant is even built

Experts offer advice on creating food and beverage processing facilities that are easy to clean, while also looking to a future that includes automating the process.

November 6, 2017

Never miss the latest news and trends driving the food safety industry

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing