Risk Assessment

Several challenges are associated with newer plant-based foods, including allergen, chemical, quality, and microbiological concerns

Read More

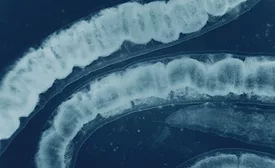

The Rise of Antimicrobial Coatings Usage and Standards

A renewed interest in the use of antimicrobial coatings in the food sector has been observed with the COVID-19 pandemic

February 22, 2022

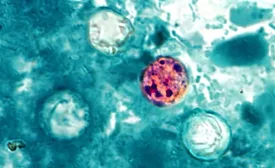

Foodborne Parasites: An Insidious Threat to Food Safety and Public Health

Often neglected in risk assessments, foodborne parasites deserve more scrutiny—and prevention

October 18, 2021

Improving the Safety of Meal Kits: A Holistic Approach

Popularity of meal kits necessitates heightened food safety vigilance

October 18, 2021

Coliforms vs. Cybersecurity: How Metrics Can Help Food Safety “Compete” with Cybersecurity and Other Enterprise Risks

Empowering food safety professionals to fight enterprise risks

August 22, 2021

Beyond HACCP and Preventive Controls: Promoting True Risk-Based Thinking Tied to Public Health Outcomes

Rethinking preventive approaches to food safety

June 20, 2021

Never miss the latest news and trends driving the food safety industry

Newsletters | Website | eMagazine

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing