Antimicrobial Phage Spray Effective Against Foodborne Bacteria, Including Multidrug Resistant E. Coli

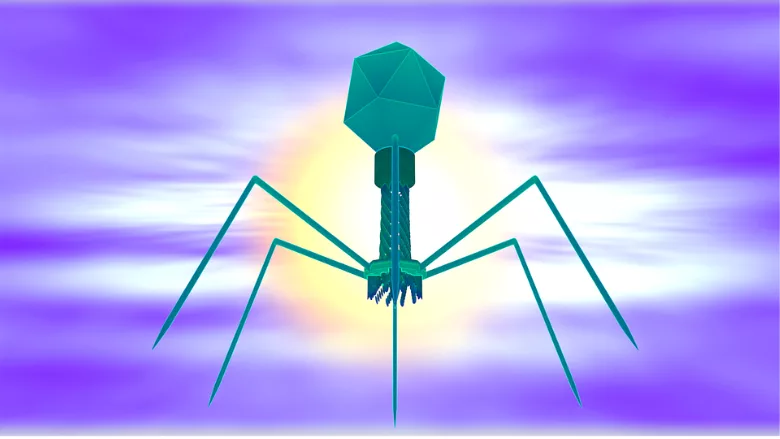

Credit: sbtlneet (sbtlneet-3591002) via Pixabay

Researchers at McMaster University have developed a new, highly effective tool to mitigate bacterial contamination of foods, including pathogens displaying antimicrobial resistance (AMR). The technology involves the application of bacteriophages (phages)—benign viruses that eat bacteria—to goods in the form of microgels.

Phages are natural predators to bacteria, and because phages attack bacteria in a highly targeted manner, they can be used in food and agriculture without disturbing the balance of microbial communities. Phage products have been approved by the US Food and Drug Administration (FDA) for controlling dangerous bacterial contaminants such as Escherichia coli in food products. Though they do not affect the taste, texture, and nutritional quality of foods, phages are not widely used by industry due to challenges with delivery and stability of phage products.

The researchers discovered a method of facilitating linkage between phages so that they form microgels made up entirely of viral nanoparticles, preserving phage bioactivity in the process. Microgels have advantages when it comes to the application of phages, such as larger surface areas enabling more contact points for contaminating bacteria. Microgels can also be applied as a pray or via injection, making them a versatile tool. The researchers’ high-throughput method was able to produce over 35,000 phage microgels in every square centimeter, with each microgel containing half a million phages.

The researchers demonstrated the antimicrobial activity of the phage microgels against multidrug resistant Escherichia coli O157:H7. Microgels were applied via a spray to lettuce, resulting in a reduction of E. coli to undetectable levels after 9 hours. The microgels were also sprayed on meat samples and eliminated 99.4 percent of the pathogen.

The technology has great potential for food safety, as the researchers are confident in the microgels against other important foodborne pathogens, such as Listeria monocytogenes and Salmonella. Phage sprays can also be used in a variety of contexts, including in food processing, packaging, and cleaning, and as a treatment for irrigation water and equipment.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →