AAMP

Bacteriophages and application in the meat industry

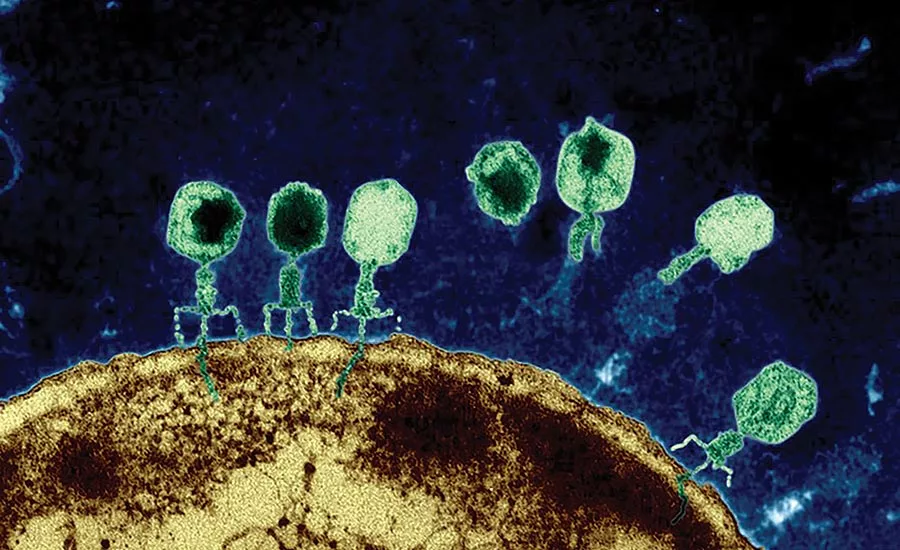

Figure 1: A group of phages, in green, attacks an E. coli cell, injecting their DNA through the cell membrane. (Source: Image from Eye of Science / Science Source)

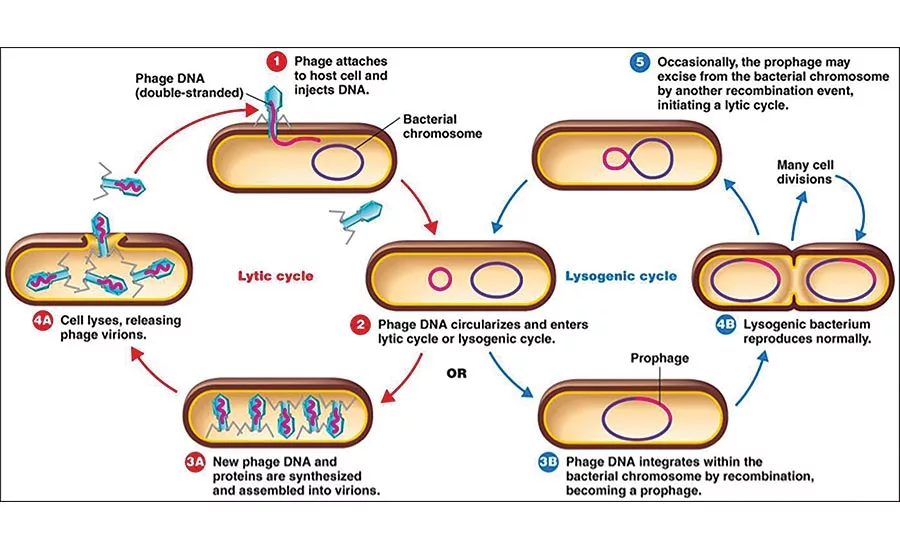

Figure 2: The Lytic and Lysogenic Cycles of Bacteriophage. (Source: https://bit.ly/2HUUIBk)

Today the concerns of environmental and product contamination and potential foodborne illness have never been greater. Increasing concerns of the overuse of antibiotics and the negative consumer perception of chemical preservatives in the food industry have spurred an interest for more “natural” antimicrobial compounds.

Bacteriophage, also known as phage (/fãj/) fit into this growing category.

Phages are viruses that infect bacteria, and only bacteria (Figure 1). They are ubiquitous, meaning there are found everywhere with an estimate of more than 1031 (ten million trillion trillion on the planet); that’s more than the sum of every other living organism on Earth. These viruses are highly specific and only target a certain species of bacteria. They do this by recognizing very specific receptors on the surface of bacteria and then attaching. A phage that attacks Listeria would have no effect on Salmonella or E. coli. Phages are also harmless to all other organisms such as eukaryotic (human and animal) cells, plant cells and fungi.

Phages are classified as obligatory parasites meaning they cannot reproduce and complete their life cycle without a host. Phages can infect a bacterial host through two different life cycles: the Lytic Cycle and the Lysogenic Cycle.

The steps of each life cycle can be seen in Figure 2.

Some phages can only reproduce through the Lytic Cycle where they burst out of and kill their bacterial host (lyse). This entire process can take between several minutes to several hours depending on the environment and other factors like: the amount of phage or bacteria present, type of bacteria targeted and how well the phages are distributed. Other types of phages can alternate between the Lytic Cycle and the Lysogenic Cycle where the host cell is not killed but kept alive to pass along the phage DNA. Phages that strictly follow the Lytic Cycle are more applicable in the food industry.

Phages have four main applications in the agricultural industry (from Sillankorva et al, 2012):

- Therapy – reduce colonization in living animals during production

- Sanitation – disinfect food contact surfaces and equipment

- Control – reduce colonization on food products at processing facilities

- Preservation – prevent contamination and pathogen growth on foods during storage and transportation

The last three are very applicable in the meat industry. The dose of phages applied, how it is distributed, and the dwell time are important factors to consider when spraying phage onto food products, food packaging or food contact surfaces. Phages themselves are not motile, meaning they cannot move independently so they require moisture to travel and come in contact with bacteria. This also means that phages are only effective on the surface of meat and other food products. Phages can be sprayed onto the surface of raw materials, onto Ready-to-Eat (RTE) products or into packaging materials before the product is placed inside and sealed. Below is a list of benefits and limitations to using phage.

Benefits:

- High specificity when targeting bacteria, which leaves human, animal and plant cells as well as “good bacteria” untouched

- Are self-replicating and self-limiting microorganisms, meaning that they will continue to replicate and kill bacteria as long as their target bacteria is present

- Continuously mutating and adapting to their bacterial hosts’ defense mechanisms

- Cocktails of different phages have been shown to be effective together

- Approved by both the FDA and USDA and certified GRAS

- Shown to work on a wide range of temperatures including refrigeration

- Shown to work well on biofilms

- Impart no taste or smell on food products

- No worker safety issues

- Non-corrosive to equipment and environmental surfaces

- Generally carry a positive perception with consumers since other “good microorganism” are known to aid in the production of alcoholic beverages, yogurt and fermented meat products.

Limitations:

- Completely ineffective if targeted bacteria are not present

- Bacterial resistance can develop

- Vulnerable to all factors that can harm bacteria such as: heat, salt, low pH, and sanitizers

- Phages, unlike bacteria, lack repair mechanisms so any damage taken from the factors above is permanent. This means phage populations typically will be more heavily killed off than bacteria

- Requires moisture to help transport

- Can’t differentiate between pathogenic and non-pathogenic bacteria (ex. E. coli) and can unintendedly kill beneficial bacteria.

Bacteriophages are not an end-all permanent solution to bacterial contamination and foodborne illness, but it can be an effective addition to your hurdle technology system. Future research in this area is growing and looks promising.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →