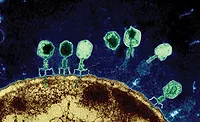

Bacteriophages: Natural disinfectants

As consumers increasingly demand antibiotic-free meat and poultry (and processors look to avoid antimicrobial resistance), alternative treatment and disinfection methods such as bacteriophages should become more popular in food and medicine.

Just this spring, a dying patient with multidrug-resistant bacterium was saved with emergency cocktails of bacteriophages.

Simply put, phages are viruses that target and attack bacteria. “Phages are everywhere so they are not inherently dangerous,” says Jason Gill, Ph.D., assistant professor of bacteriophage, biology and microbiology and program director of the Center for Phage Technology at College Station, Texas-based Texas A&M University. Gill’s team assisted with the sick patient. “But all companies working with them need to know what they’re doing, so there are no deleterious side effects.”

Generally phages are disseminated in a spray or nebulizer, he says.

“Processors prefer to use them on product surfaces,” notes Gill. “The phages won’t change the product or taste, but create a diluted buffer. Often, they are put on right before the item is vacuum packaged.”

While most phages are applied post-harvest, they can also be used pre-harvest to control the hot spots in beef facilities, such as drainage spots, or on hides before slaughter.

The drawback to using phages as sanitizers is that bacteria in processing facilities could develop resistance to them, says Laurence Goodridge, Ph.D., associate professor and Ian and Jayne Munro Chair in Food Safety at McGill University, based in Montreal, Quebec.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

“If phages are sprayed on meat, even if the bacteria becomes resistant, the difference is that they [pathogens] can’t reinfect a surface in the plant,” Goodridge says.

Formulating better applications

Phages can also be used to detect pathogens faster. “During the enrichment step of the testing protocol, phages can speed up the detection process,” says Bruce Applegate, Ph.D., professor of food science and associate professor food science, at Purdue University, in Lafayette, Ind., whose team created NanoLuc phages.

The NanoLuc cells cause E. coli O157:H7 bacteria to glow if they connect, so processors can see whether the product is contaminated.

“Phages can be very effective for some applications, but there’s a huge range of conditions that phages might encounter in foods and food processing plants,” says Thomas Denes, Ph.D., assistant professor in molecular food microbiology at University of Tennessee, in Knoxville, Tenn. “We might be able to further improve the efficacy of phage-based biocontrol by formulating phage cocktails for use under specific conditions.”

Targeting more pathogens

Clustered regularly interspaced short palindromic repeats (CRISPR) technology aims to increase the functionality of phages so they can infect more than one pathogen, amongst other initiatives, he notes.

“There’s a lot of work being done with genetic modification of phages so they can target more pathogens,” he says. “Generally, they only target one type of bacteria, but we know any contaminant can be in animals at the same time.”

Treating the original source — animal health — with phages before pre-treatment intervention may be the next logical step.

“The challenge for animals is different because bacteria is hidden in their biofilm — a carpet of bacteria,” Goodridge says. “So it’s hard for bacteriophages to target this bacteria.”

Will consumers be on board with the increased use of phages?

“When phages were approved for use in the United States 11 years ago, there was huge backlash,” Goodridge says. “People saw the word ‘virus,’ and they got nervous. But now they realize phages are natural, naturally occurring, everywhere and where pathogens are, so they are more accepting.” NP

This article was originally posted on www.provisioneronline.com.